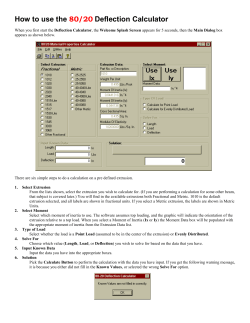

Document 364116