Document 376721

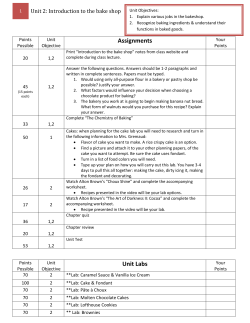

no; ‘763,089. 7 , PATENTED' JUNE 21, 1904.. W. B. CRANE, DEC’D. ' A. B. Jonson. Anu'm'iswumon. APPARATUS FOR THE PRODUCTION OF ICE. ' APPLICATION npnn SEPT.18,'1899. I0 MODEL. V _ ' ‘ 3 SHEETS-SHEET 1. (éM/Jfw-mVm/rm. * WMAMW ATTORNEY: No. 763,089. PATENTED JUNE 21', 1904.’ W. E. GRANRDEG'U A. n. Jonson. Anmms'rmwon. APPARATUS FOR THE PRODUCTION 0]? ICE. ~ no MODEL. ' “53' ‘ APPLICATION FILED SEIPTJBLNQQ. 3 sums-sum‘ 2‘. ‘I I “$5.2. i | | II' “8.5. v ' __'____ / Q I md , .4 TTORNE x ‘m: Nonms PETERS co.. Pnoraumm WASHINGTON, o. c. Inn-763,089. ‘ PATENTED JUNE 21, 1904. W. E. CRANE, DEG’D. A. R; JOHNSON. ADMINISTRATOR. APPARATUS FOR THE PRODUCTION OF ICE. APPLICATION FILED SEPT.1B, 1899- NO MODEL. ‘ ' ' v 3 SHEETSr-SHBET 3. QA M _ may f). 4.7 / . - m: moms runs cov PHOTOJJYHOJVASHYNGTON. D c ATTORNEY . ?atented June 21, 1904. 1 No. 763,089. UNITED STATES PATENT OFFICE. WALTER ELIPHALET‘ORANE, OF MINNEAPOLIS, MINNESOTA; A. ROLAND JOHNSON ADMINISTRATOR OF SAIDORANE, DECEASED. APPARATUS FOR THE PRODUCTION OF ICE. SPECIFICATION forming part of Letters Patent No. 763,089, dated June 21, 1904. Application ?led September 18, 1899. Serial No. 730,911. (No model.) pf my invention may be brie?y stated, as fol- 50 To all, whom it may concern. Be it known that I, WALTER ELIPHALET CRANE, a citizen of the United States, resid ing at Minneapolis, in the county of Hennepin 5 and State of Minnesota, have invented certain new and useful Improvements in Apparatus for the Production of Ice, of which the fol lowing is a speci?cation. i ' ows: _, First. To provide a practical and efficient means for freezing on successive additional layers at the formative end of the cake. This object I accomplish by the provision, in con- 5 5 nection with freezing-plates, of meansfor suc- ’ cessively lowering and raising the temperature . My invention relates to the production of of said plates below and above the freezing point and means for intermittently moving by “arti?cial means,” so called, by repeatedly the progressively-formed cakes of ice away 60 freezing successive thin additional layers to from the freezing-plates by short steps of the so-called “ formative end ” of the cake be movement immediately after the last frozen IO ice in merchantable cakes or commercial form ing formed. 15 . Generally stated, this invention has for its object to provide an improved apparatus for layer of the cake is thawed loose from the said ' freezing-plates. Second. To form a series of ice-molds with 65 carrying out a novel process or method, which the freezing-plates so disposed as to obtain ' ‘20 will incidentally appear in the following de the maximum efficiency with the resulting scription, but which is the subject-matter of minimum of waste by radiation of heat, to so a separate application, ?led as a division of construct and arrange such freezing-plates this original application and bearing Serial that the impurities of the water will not be 70 No. 738,293, ?led November 27, 1899, entitled caged or caught in the freezing process, with the result that the ice is left pure, and to ef “Method of producing ice.” It is a known fact that the resistance of ice 25 to the passage of heat increases about in pro portion to the square of its thickness or the distance through which the'heat is to be con ducted. It therefore follows that ice ?ve and fect an economy in space occupied by the series of molds. , These objects I accomplish by the provision of wedge - shaped molds '75 formed between divergently and vertically disposed freezing-plates that are common to one-half inches thick, for example, would adjacent molds. These wedge-shaped molds 30 offer about four hundred and eighty-four are placed in a water tank or receptacle below times as much resistance to the passage of the Water-level thereof, and to secure the best heat as ice one-fourth of an inch in thickness ‘results the bottom of the freezing-plates and one hunched and twenty-one times as should be terminated some distance above the much as ice one-half an inch in thickness. bottom of said tank and the upper end below 35 Again, a layer of ice one-fourth of an inch in the water-level, so as to permit the free cir thickness may be easily frozen in two minutes, culation of the water and the escape of the while it requires to freeze to the center of a impurities. Third. To provide a form of freezing-plate can of ice eleven inches thick or to freeze progressively five and one-half inches, for in which the freezing will be slightly more 40 example, sixty hours in ordinary practice. rapid at the central or intermediate portion ' Hence it is of course desirable for the sake of thereof, so that the impurities-in the water economy in time, cost, and space to limit to a will be forced outward and ejected from the minimum the distance through which heat region wherein the freezing of the water is must be conducted in the progressive forma taking place. This I accomplish by forming 45 tion of the ice cakes. My improved appa the hollow freezing plate or member with in ratus, hereinafter described, has been designed gress and egress passages and with expansion to especially accomplish this result. 30 35 90 95 chambers or compartments that progressively ~ In accordance with the desired ends above increase in capacity from the point of ingress ~ indicated several of the more speci?c objects to the point of egress. 2 ‘763,089 Fourth. To provide an apparatus for the ness of the cake of ice it is desired to make, as manufacture of ice in which the operation is eleven inches thick, the plates 2)’ and p2 are bent very rapid, with the result that a large quan outward at an angle one-half as great as the an tity of ice per day may be turned out or pro duced from a comparatively small and inex gle between adjoining plates that this portion 1f’ and p6 of the plate may lie approximately pensive plant, thereby making possible the parallel with the sides of the cake of ice 1. production of ice at a comparativelylow cost. The width of this slanting portion 195 and )2“ 10 Other minor objects and features of my in vention will appear in the detailed description of the apparatus. The invention consists of the novel devices and combinations of devices heretofore noted and to be hereinafter noted, and to be particu larly set forth in the claims. The invention is illustrated in the accompa 70 of the plate P is made about equal to the nec essary movement of the cake outward to pro duce the desired separation of the cake I from 75 the freezing-plates P. The shaping of the plates thus is to insure the side surfaces of the cake being made smooth. The end' pieces [)7 and p“ of the plate Pare so shaped as to con form to the shape of the opening between the nying drawings, wherein, like characters in— side plates p’ and 122, Fig. 7, and the riveting dicating like parts throughout the several together of these four parts to constitute the views‘ ’ Figure 1 is a plan view of the circular freez 20 exterior of the plate is to be so done as to make the plate perfectly gas-tight. ing-tank, showing the series of twelve freez Secured in any desired manner, as by screws 85 ing-plates, also the twelve cakes of ice being or rivets, to the interior of one or both of the formed, and one of the controlling-frames with plates 1)’ and p2 are partitions p" and p10, bent its guides. Fig. 2 is a side elevationof one U-shaped, and also partition 19“. These par of the controlling-frames with a portion of a titions are of the same width as the end pieces 25 cake of ice inclosed therein. Fig. 3 is an end 127 and p8 and are intended to make approxi 90 elevation, partly in section, of the so-called mately tight joints with the side plates in or “ controlling — frame” or “ ice - controlling” der to effectually direct the movement or ?ow frame shown in Fig. 2, showing the means for securing the cake _of ice in the frame. Fig. 4 is a plan view of the controlling-frame, show ing also a portion of one of the guides which support it in position in the tank. Fig. 5 is a view similar to Fig. 3 of a portion of the 397 of the plate P are the inlet-pipe p12 and the larger outlet~pipe pm, which are provided with controlling-frame, showing the securing de through the top end piece 127. 35 vice in a released position. of the refrigeri?c element. ‘ Projecting ‘down through the top end piece suitable stop-valves p“ and p15, and these pipes are made perfectly tight where they pass Fig. 6 is a verti One object of the partitions p“ and 12"’ is to cal elevation of one of the hollow freezing partially con?ne the ammonia or other refrig plates with the front side of the same re eri?c agent used as it ?rst expands at the en moved to show the arrangement of the pipes tering-nozzle 321“ by means of the partition 1)”. and partitions of the interior. Fig. 7 is a sec Then let it ?ow into the larger space at both 4.0 tional view of a freezing-plate on line 3/ 12/ of I00 sides of partition 12” and nearly inclosed by Fig. 6. Fig. 8 is an elevation similar to Fig. the partition 1910, then into the still larger 6 of a freezing-plate, showing the partitions space outside of that inclosed by partition 121°, and inlet-pipe in a modi?ed form. Fig. 9 is thus not allowing the expansion to take place a sectional view of a freezing-plate on line :0 :20 wholly at one spot and providing also for a 45 of Fig. 8. Fig. 10 is a section view of a freez nearly uniform circulation within all parts of ing-plate, showing a modi?ed form of con the plate P. With the above arrangement of structing the outer shell of the plate. Fig. 11 the partitions within the plate there will still is a View of the inlet or outlet pipes (which be somewhat greater expansion of the refrig may be similar) for the freezing-plates, show eri?c element in the vicinity of the center of ing the valves for the alternate admission or the plate than toward the edges thereof, and exit of the freezing or thawing agents. this is desired to a certain degree in order I10 The freezing-plate P, Figs. 1, 6,yand 7, is a that the freezing of the “additional layers” hollow rectangular plate of a length fully as may be ?rst completed at the center and then great as the length of the cake of ice it is de progress rapidly outward, that the impurities 55 sired to make, and its outer shell or exterior will be discharged rather than imprisoned and I20 is constructed, preferably, of two thin sheets frozen in. The outlet-pipe 321'" receives and of metal 12’ and p2, bent, as shown, so as to be conducts away from the plate P the fully-ex riveted together at the two vertical edges of panded ammonia~gas or other refrigeri?c ele the plate 1)“ and 1)‘, and also of two end pieces ment and has holes or perforations p" for the p7 and j)“ at the top and bottom of the plate reception of the gas, as well as the opening at :25 and through which the side plates 12’ and p2 the lower end of the pipe. are also riveted together. At such a distance In Fig. 8 is shown a modi?ed form of con radially outward upon the plate P (see Fig. 1) struction of the partitions ‘within the plate P, as will make the divergence between the sur in which the refrigeri?c element is admitted 65 faces of two adjacent plates equal to the thick to the plate through a double nozzle 1218 into 130 763,089." 3. the gradually-expanding compartments in iron. These angle-iron frames are secured closed by the E-shaped partitions p1” and p20. together at the corners by small plates f‘“. The partitions p21 are designed to divert a The controlling-frame F is provided with a portion of the refrigerant to the extreme cen seeuring- frame composed of the bent bars 5 tral right-hand portion of the plate. f6 and f7, connected together by the bars f3' and f9, and‘ in these are securely ?xed the struction of the plate P from that shown in spikes f”. A support f“ is secured to the Fig. 7, in which the side plates 1)’ and p2 ter top of the controlling-frame, and in this is ful minate at the edge of the slanting portion 1)“ crumed a lever f 12, which is connected by link IO and p“, and instead of their being bent so as f13 to a casting f“, secured ?rmly to cross-bar 75 In Fig. 10 is shown a modi?ed form of con to be secured together, as at 793, they are con nectcd by a separate piece ?anged at both edges 1)“, through which they are riveted or otherwise secured to the side pieces at p23 and 15 192*. The advantage of this form over that shown in Fig. 7 lies chie?y in the ease and convenience of construction. Fig. 1 shows twelve of these freezing plates P placed on suitable supports and ar 20 ranged equidistantly spaced in a circle about a common center and concentric with the cir cular tank T, in which they are placed. This tank T is of sufficient depth to have the plates P set up from the bottom upon the timbers g‘, 25 Figs. 2 and 3, which also support the guides G, as will hereinafter be explained, and in f8 of the securing-frame. The leverf12 is pro vided with a. pawl f“, connected in the usual manner with handle-piece f1“, and to the top of the frame F is securely fastened a sector f 17, provided with notches for engagement with the pawl f“. The lever f 12 extends above the ?oor (not shown) of the tank T, and by means of it the operator may easily secure the cake of ice within the frame F by placing the lever in the position shown in Fig. 3 or 85 release the cake of ice by placing the lever in the position shown in Fig. 5, which shows the securing-spikes withdrawn from the cake of ice. In operation the frame F is released from the cake of ice immediately after the two additional layers have been frozen fast to addition is deep enough to allow of the com-, the cake, is then moved a short distance toplete submerging of the plates P without ward the center of the tank, and is then over?owing the tank. With the freezing‘ again secured to the cake of ice. The cake of 30 plates thus raised from the bottom of the tank ice is then thawed loose from the freezing 95 T the cakes of’ ice I will be formed entirely plates I by ?rst cutting off the refrigeri?c above the sediment in the water which accu ?uid and then letting a relatively warm gas or mulates in the bottom portion of the tank. ?uid for a. short interval of time circulate The tank T is provided with a supply-pipe 25’, through the said so-called “ freezing-plates.” 35 through which water,preferably cooled nearly The cake of ice is then, by means of the frame 100 to the freezing-point, is admitted and kept at the proper level in the tank. The tank is s also provided with an overflow-pipe t2, which leaves the tank at the distance from the top 40 where it is desired to maintain the surface of the water. The tank is also supplied with one or more discharge-pipes 29, leaving the tank at the bottom, by means of which the scttlings may be drained off from the bottom 45 of the tank or by which the tank may be en F, moved the proper short distance away from 5° the. cakes of ice are formed are twelve con freezing-plates. The guide 92 for the left 115 the freezing- plates. Thctmovement of the cake of ice separates it from the freezing-plates sufficiently for the formation of the succes sive additional layers of ice. The frame F is 105 provided with projections f’ 18, extending out ward from the sides at the bottom in position and adapted to project into grooves g’ in the sides of the guides G, Figs. 1, 2, and 3. The guides G are made double-that is, a right tirely emptied for the purpose’ of washing it and a left guide together in the form of a V~ out or to obtain access to any of the ordina and are ?rmly secured to the top of tim rily submerged parts. Located opposite each bers g‘, which are placed in the bottom of the opening between the freezing-plates where tank for the support of the guides G and the trolling-frames, (only one of which is shown side of the frame F has formed integral there in Fig. 1,) by means of which the cakes of with a raised portion provided with the ver ice are held in, proper position with reference tical teeth or rack (3, and the frame F is pro to the freezing-plates and are moved radially vided with bearings f1” and f2“, in which is 55 to separate the cakes from the plates after mounted an upright shaft 3”‘, having secured each successive freezing operation. This con to it a hand-wheel f22 and pinion f23 in posi trolling-frame has an opening through it in a tion and adapted to engage with the rack g", radial direction of sufficient height and width . and by means of these the frame F is moved I10 I20 to freely admit through it a cake of ice as by the operator after each freezing operation, 60 large as may be frozen by the freezing as beforemention ed. The securing-spikesf 1" 125 plates. This controlling-frame F is composed pass through the holes in the frame F, and of top plate f’, bottom plate f2, and side therein act as vguides for the movement of plates f’f", which are properly secured to the securing-frame when moved by the lever the inner side of two end frames, composed, f”. For the sake of greater clearness the 65 preferably, of side and end strips of angle guides Ur and timber g‘1 in Fig. 3 are both. 4.» ‘763,089 shown in section, as at line 10 Figs. 2 and 4». ively - formed cake may be said to be the The tank T is made of sufficient diameter to allow of the extension of the cakes of iceI to such a distance radially from the frame F as will admit of a block of ice of a desired width, “formative” end of the cake. 1n virtue of the fact that the freezing-plates which form the wedge-shaped molds are vertically dis posed and are set slightly above the bottom (as twenty-two inches,) 12, being sawed off or of the tank and below the level of the water, otherwise severed from the continuous cake thus leaving the mold open at its top and bot being formed by any suitable means, (not tom, permits the natural circulation of the 'shown,) approximately where shown by the water due to convection, and hence in “freez dotted line 13. As one after another f the ing'on the additional layers” the impurities 75 cakes of ice attain the proper length they are of the water are free to settleor to ?oat from severed by the operator and the separated the freezing zone up to the‘very last stage of cakes removed by any suitable means from the these comparatively short operations. Those impurities which settle may be drawn off Fig. 11 represents an arrangement of the from the bottom of the tank from time to admission-pipe pm, which is provided above time and an additional supply of fresh water the stop-valve p“ with a T and opposite substituted for the water Wasted by this oper tank. 20 ' _ branch pipes 1225 and pm‘, each having an ad ation. Likewise those impurities which ?oat mission or regulating valve 19277228. One pipe, may be skimmed from the surface of the as p25, connects with the supply of liquid am water within the tank, and it will be under 85 monia or other refrigeri?c element, and the stood that the water in the tank will be kept other pipe, 12%, connects with a thawing agent, at such a level that it will fully cover or sub as heated expanded ammonia- gas or other merge the freezing-plates. ?uid or gas having a temperature above the 25 freezing-point. The arrangement of the exit It will of course be understood that the ap paratus above described is capable of a large pipes may be exactly the same as to branches range of modi?cation in construction within and valves as those for admission. During the scope of my invention. I do not, of course, . the continuance of the freezing operation the limit myself to any de?nite number of freez valve 111" is open, the valve 1927 partially open ing-plates in the series or circle or to the cir or regulated to admit the proper amount of refrigeri?c element, and the valve p28 closed cular or radial arrangement thereof, as the 95 number might be greater or less than shown ‘ to shut out the thawing agent, while the valves in the drawings, and the said freezing-plates of the exit-pipe are in a similar position. At might be differently disposed, although there the time of completion of the freezing opera are advantages in the circular or radial dispo 35 tion the valve 1227 is closed and the valve 122“ sition of the said plates. Also, so far as the opened and regulated to allow the admission broad idea of my invention is concerned, the of a proper amount of the thawing agent, and so-called s‘adjusting-frames ” for moving the the valves of the exit-pipes are similarly re cake of ice progressively might be very con versed to deliver the warmer or thawing siderably modi?ed. I00 , agent instead of the expanded refrigeri?c ele The timbers g‘, which support the freezing 105 ment to its appropriate receptacle. plates and the guides in the tank, are cut down If deemed desirable, the twelve inlet-pipes for the guides, the portion which supports the for the whole series of freezing-plates may freezing-plates being of substantially the same be joined together and combined to form the height as the top of guide G, as shown at the 45 pipe 171?, that they may be manipulated simul left side in Fig. 3. This brings the bottom I10 taneously and as one. The exit-pipes may also be joined and operated as a unit. As a matter of convenience it may be deemed de sirable to connect the inlet and outlet pipes, respectively, into two or three groups for the series, that the attention of the operator may be given to the manipulation of the control ling-frames more promptly after the thawing loose of the freezing-plates. 55 The series of ice-controlling frames F may be said to alternate with the series of freez ing-plates, as they occupy intervening radial positions with reference to the freezing end of the freezing-plates on a level with the lower edge of the cake of ice formed thereby. It will be further understood that many modifications of the construction above de scribed may be made within the scope of my 115 invention. . ‘What I claim, and desire to secure by Let ters Patent of the United States, is 'as follows: 1. In an apparatus for the production of ice in cakes, the combination with a tank adapted to contain the water to be frozen, of a series of separated, vertical, radiating, substantially ?at freezing-plates, ?xedly sustained below plates. The freezing-plates being arranged the water-level of the said tank, and forming equidistantly disposed in a circle from the the water into V-shaped portions between the I25 center of which they radiate, they are there adjacent plates of the series; a like series of fore uniformly divergent one from another. ingress and egress pipes connecting the said The cake of ice as it is formed from between plates respectively with the refrigeri?c ele the diverging f reezin g-plates is wedge-shaped, ment; and an auxiliary series of pipes in po 65 and this wedge-shaped end of the progress sition and adapted to‘ enable substitute connec 130 763,089 , 5 -' tion to be made at will, of the said plates with ing free communication between the said V shaped portions of water and the water in a thawing element. 2. In an apparatus for the production of ice the exterior and top and bottom portions of in cakes, the combination with a tank con the tank, and limited communication with taining the water to be frozen, of a series of the water in the center of the same; ingress IO 15 separated, radially-disposed, hollow freezing plates, each having substantially parallel prin passages from a source of supply of a re said plates. said plates to said blocks of ice shall be first So in cakes, the combination with a tank con taining the water to be frozen, of a series of impurities toward and past the edges of the frigeri?c element to the central portion of cipal surfaces, and ?xedly secured in vertical each of said freezing-plates; return-passages position submerged in the said water; ingress from the outer portion of each of said plates; and egress passages connecting each of said and the same being all arranged in suitable 75 plates primarily with a refrigeri?c' element, operative positions with reference to V-shapcd and secondarily with a thawing element; and blocks of ice supported with their diverging means substantially as described for sustaining faces in juxtaposition to the principal sur and advancing V-shaped cakes of ice from the faces of said plates, that the freezing from 3. In an apparatus for the production of ice completed in the central portion, expelling cakes of ice being formed. ‘ 7. In an apparatus for the production of ice freezing-plates, fixedly submerged in the said in cakes, the combination with a tank contain 85 Water; ingress and egress refrigeri?c commu ,ing the water to be frozen, of a radiatingse nication with each of said plates; substitute ries of separated, vertical, substantially ?at radially-disposed, separated, vertical, hollow, , 20 ED thawing-element communication with each of said plates; a series of radial guides alternat ing with said freezing-plates; and a like series of sustaining and controlling frames mounted in the said guides, and adapted to alternately hold and advance the cakes of ice progressively formed by the said freezing-plates. freezing-plates submerged in the said water; ingress and egress refrigeri?c communication with each of said plates; substitute circula 9O tory thawing-element communication with each of said plates, the same being .in suitable operative relation and position to a like se ries of blocks of ice having V-shaped' inner 4. In an apparatus for the production of ice ends, supported with their diverging faces in 95 .30 in cakes, the combination with a tank adapted juxtaposition to the principal surfaces of said to contain the water to be frozen, ofa circular plates; and minorv inclined surfaces of the said series of separated, vertical, hollow freezing plates, each substantially parallel with the plates ?xedly sustained beneath the working mating surface of the adjacent plate, and con 35 water-level of said tank; ingress - passages tiguous to the parallel sides of the inclosed 40 I00 from the source of supply of a refrigeri?c block of ice. 8. In an apparatus for the production-of ice element to the central portion of each of said freezing — plates; return - passages from the in cakes, the combination with a tank contain outer portion of each of said plates; substi ing the water to be frozen, of a series of sta tute circulatory passages from each of said tionary separated, vertical, diverging freez 105 ing plates or members of rectangular hollow dium; and means substantially as‘ described, form, radially disposed to form a series of for sustaining and intermittently advancing wedge-shaped molds or openings, the said the cakes of ice progressively formed in the plates being common to the center of the tank plates to a source of supply of a thawing me 4-5 divergent openings between the adjacent and forming vertical walls of adjacent molds, in which cakes of ice are progressively formed. 9. In an apparatus for the productionof ice 5. In an apparatus for the production of ice in cakes, the combination with a tank contain in cakes, the combination with a tank contain ing the water to be frozen, of. a series of ra ing the water to be frozen, of a horizontally 50 dially - disposed, separated, vertical, hollow disposed series of independent, stationary, sub ng freezing~plates, fixedlysubmerged in the said merged freezing-plates radiating from a com water; ingress and egress refrigeri?c commu mon center of said’ tank, to form intervening nication with each of said plates; and substi molds for the water to be frozen while the tute ingress and egress thawing-element com same is in free communication with the water I20 1 55 munication with each of said plates, the said in the tank. 1.0. In an apparatus for the production of ice communications being in position and adapted plates of the series. for greater refrigeri?c activity in the cen in cakes, the combination with a tank or recep tacle for the water, of a series of freezing-plates 6. In an apparatus for the production of ice radiating from acommon center within said tank and forming a series of wedge-shaped 60 in cakes, the combination witha tank contain ing the water to be frozen, of a radiating se molds, having vertical walls, and an alternat tral portion of the plates. \ ries of separated, vertical, substantially ?at ing series of radially-movable ice-supporting freezing-plates submerged in the said water, frames, substantially as described. 11. Ahollow freezing plate or member hav forming it into V-shaped portions between the adjacent plates of the series and allow-' ing ingress and egress passages and expansion- ’ 130 S 763,089 compartments progressively increasing in ca end of said partition; and an outlet-pipe coin? pacity from the point of ingress to the point municating with the space outside of said in of egress. 12. A hollow freezing plate or member hav ing an ingress-passage opening into the inter mediate portion of the same, and an egress IO closing partition, to provide duplex expand ing circulatory passages for the refrigerilic element. _ 15. In a hollow freezing-plate, the combina passage opening from the marginal or outer tion with an inlet-pipe opening at or near the portion of the same, and having interior ex central portion of the plate, of duplex expand pansion—compartments intermediate of said ing compartments extending from the central passages increasing in holding capacity from portion to the exterior portion of said plate, the former to the latter, substantially as de and an outlet-pipe in connection with saidex scribed. terior portion, substantially as described. 13. In an apparatus for the production of ice 16. In an apparatus for the production of ice in cakes, the combination with freezing plates in cakes, the combination with a guide pro or members constructed with a central admis vided with a parallel rack, of an ice-control sion and successively larger compartments to ling frame mounted thereon; a wheel and pin their outlet, providing greater refrigeri?c ac tivity at their center and intermediate por 20 ion engaging With said rack; ice-supporting sides at right angles with each other in said' tions, of circulating connections thereto for frame; a series of spikes adapted to sustain a 45 alternately admitting to said plates a refrig cake of ice against said supporting sides; and erilic and a thawing medium. a lever for projecting and withdrawing said 14. In a hollow freezing-plate, the combina tion with the side and end plates thereof, of a U-shaped central partition; an inlet-pipe pro jecting into the space within said partition; an inclosing U-shaped partition about the open spikes at will. , WALTER ELIPHALET CRANE. Witnesses: JOHN V. .KRANZ, O. F. GUs'rArsoN.

© Copyright 2026