Lockout... Tagout... Tryout !

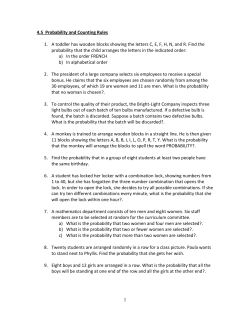

Lockout... Tagout... Tryout ! Failure to lock, tag and try electrical equipment is one of the top 5 causes of all fatal mining accidents. A presentation of... Metal and Nonmetal Safety & Health Count the Cost of Not Locking Out... Metal-Nonmetal Electrical Lockout Injuries over 10 Years: 30 6 257 45 Fatalities Permanent disabilities Lost time injuries Restricted day injuries A miner was fatally injured in this log roller when the motor was started while he worked inside. Electrical power had not been disconnected. This tragedy could have been avoided had the victim locked out the power to the machine. A miner was electrocuted when his hand came in contact with 480 volts. He did not lock, tag & try, nor was he wearing electrically rated gloves. Two men were injured when this distribution panel shorted out during a repair. Electrical energy had not been disconnected and locked out. Energy Sources to Control • • • • • Electricity Machinery Pressure lines & vessels Sliding / falling material Miscellaneous Hazardous energy must be controlled when: • • • • • Removing guards, covers, shields Performing maintenance Inspecting equipment internally Troubleshooting Unchoking Workers At-Risk The vast majority of electrical accidents occurs while work is being performed on energized circuits during maintenance or troubleshooting. Even the most qualified personnel sometimes seem to disregard the dangers and risks involved. Reasons Given for Not Locking Out • Waste of time - lost production time • Supervisor praise for fast repair • Only takes a ‘minute’ for repair on “energized” equipment • Fatigue: too far or too much trouble to turn off power • Finish undesirable task quickly • Finish before going home Why to Lock Out For myself For my family For my co-worker For my profession For my company Federal Regulations Distribution Boxes 30 CFR 56/57.12006 • Distribution boxes shall be provided with a disconnecting device for each branch circuit. Such disconnecting devices shall be equipped or designed in such a manner that it can be determined by visual observation when such a device is open and that the circuit is deenergized, and the distribution box shall be labeled to show which circuit each device controls. A “distribution box” is an enclosed portable apparatus through which an electric circuit is carried to one or more cables from a single incoming feed line. Each cable circuit must be connected through an individual overcurrent protective device. The distribution box should be observable to indicate when the device is open and the circuit is deenergized. Where plugs are used to provide power, the plugs and cables need to be positively identified prior to any work on the equipment. Positive identification is essential to prevent an accident from occurring. The following photo displays why this is so important. Many distribution boxes and power centers have a window at each individual circuit where circuit deenergization can be visually determined Work on power circuits 30 CFR 56/57.12017 • Power circuits shall be deenergized before work is done on such circuits unless hot-line tools are used. Suitable warning signs shall be posted by the individuals who are to do the work. Switches shall be locked out or other measures taken which shall prevent the power circuits from being energized without the knowledge of the individuals working on them. Work on electrically powered equipment 30 CFR 56/57.12016 • Electrically powered equipment shall be deenergized before mechanical work is done on such equipment. Power switches shall be locked out or other measures taken which shall prevent the equipment from being energized without the knowledge of the individuals working on it. 30 CFR 56/57.12016, continued • Suitable warning notices shall be posted at the power switch and signed by the individuals who are to do the work. • Such locks or preventive devices shall be removed only by the persons who installed them or by authorized personnel. Electrically Powered Equip. • De-energize before mechanical work • Lock out power switches • Post warning notice – ID tag on lock is OK • Lock must be installed and removed only by person to whom it is issued BRANCH CIRCUIT DISCONNECTING DEVISES 30 CFR 57.12084. • Disconnecting switches that can be opened safely under load shall be provided underground at all branch circuits extending from primary power circuits near shafts, adits, levels and boreholes. Lockout Hardware Locks Multi-lock adapters Tags To quickly identify the worker who is using the lock Lockout Procedures Prepare • Pre-plan • Coordinate w/ others – Operators, co-workers, contractors • Erect barricades / warning signs Shutdown • Use stop switch • If multiple switches, use one closest to equipment • Do not use disconnect switch to stop: arcing could cause injury / damage Isolate • Disconnect from all energy sources • Insulate self from electrical power – non-conductive platform, gloves, dry clothes • Stand to side of disconnect device, not in front • Avert eyes & face Left Hand Disconnect Eyes Averted, Insulating Platform for Wet Conditions Right Hand MCC Disconnect Stand Aside, Eyes Averted Insulated Gloves for Higher Voltage Lockout • Affix lock or appropriate device to disconnect switch • Do not lock out start / stop switch • Latch shackle & remove key • Personal locks: keep key • System locks: key placed in system lock box Field Disconnect Lockout Right Wrong Main Disconnect Lockout • This shows how a main disconnect should be locked and tagged. Motor Starter Lockout • This shows how a motor starter should be locked and tagged. Single Pole Circuit Breaker Lockout • This shows how a single pole circuit breaker should be locked and tagged. Double Pole Circuit Breaker Lockout • This shows how a double pole circuit breaker should be locked and tagged. Single Pole Switch Lockout • This shows how a single pole switch should be locked out and tagged. Cable Plug Lockout • This shows how a cable plug should be locked and tagged. Latch the Lock’s Shackle !! But don’t lock through another person’s lock ! Independent Power Sources • Lock out all independent, related parts of unit or system being repaired – Valves: lock or chain – Tag & sign • Block parts that may drop, creep, drift or turn System Lockout • For related equipment groups • Provide marked locks & keys in lockable box in central location • Person in charge confirms all necessary equipment has its lock installed & key is returned to system box • Install personal locks on system box System Lock Boxes System Locks in Use #3 #1 #2 Tagout Tryout • Verify & Test – Push “Start” switch – Equipment should not start – If equipment starts, shut down & verify proper equipment is locked out – If starts & proper equipment is locked out, warn, post guard & notify immediately Release Stored Energy • Block non-electrical devices that could release stored energy • Release spring, hydraulic or pneumatic pressures Machinery Guards • Keep them in place until: – Machine is stopped – Power supply de-energized – Padlocks installed by each person Start Up Authority After Repairs • Reinstall guards first • Do not start without authority & training • Communicate with co-workers and contractors • Be certain no one is in position to be injured Lock Removal • Personal lock to be removed only by person to whom it is issued • System locks may be removed by authorized persons Emergency Lock Removal • Locks may be removed if a person has been positively determined to be in the clear. Suggestions if person is absent: – Contact via telephone at home – Time card punched out ? – Vehicle gone from parking lot ? • Complete written lock removal report Summary • Turn off equipment and disconnect power. • Lockout energy source. • Tagout the disconnecting device. • Tryout - test to assure the power is off. • Release any stored energy. • When complete… restore power and remove tag.

© Copyright 2026