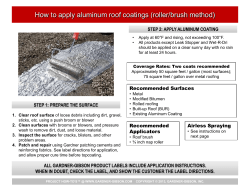

R o of ing TODAY e in