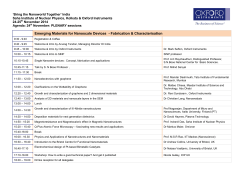

TRANSPARENT ELECTRODES FOR OPTOELECTRONIC DEVICES BASED IN ZnO AND GRAPHENE