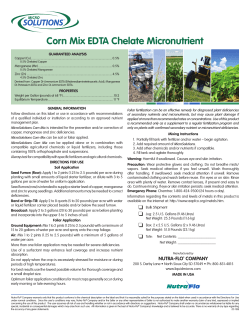

Document 439505