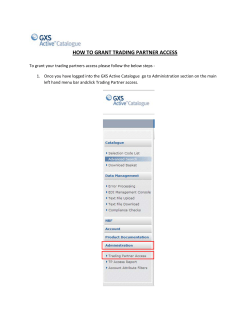

The Value of Information