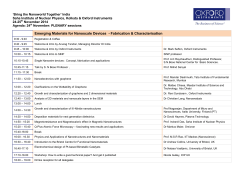

Three-Dimensional Porous Graphene-Metal Oxide

Nano Research Nano Res DOI 10.1007/s12274-014-0646-1 Three-Dimensional Porous Graphene-Metal Oxide Composite Microspheres: Preparation and Application in Li-Ion Batteries Seung Ho Choi1,2, Jung-Kul Lee2(), and Yun Chan Kang1() Nano Res., Just Accepted Manuscript • DOI: 10.1007/s12274-014-0646-1 http://www.thenanoresearch.com on November 24 2014 © Tsinghua University Press 2014 Just Accepted This is a “Just Accepted” manuscript, which has been examined by the peer-review process and has been accepted for publication. A “Just Accepted” manuscript is published online shortly after its acceptance, which is prior to technical editing and formatting and author proofing. Tsinghua University Press (TUP) provides “Just Accepted” as an optional and free service which allows authors to make their results available to the research community as soon as possible after acceptance. After a manuscript has been technically edited and formatted, it will be removed from the “Just Accepted” Web site and published as an ASAP article. Please note that technical editing may introduce minor changes to the manuscript text and/or graphics which may affect the content, and all legal disclaimers that apply to the journal pertain. In no event shall TUP be held responsible for errors or consequences arising from the use of any information contained in these “Just Accepted” manuscripts. To cite this manuscript please use its Digital Object Identifier (DOI®), which is identical for all formats of publication. 1 TABLE OF CONTENTS (TOC) Three-Dimensional Porous Graphene-Metal Oxide Composite Microspheres: Preparation and Application in Li-Ion Batteries Seung Ho Choi1,2, Jung-Kul Lee2,*, Yun Chan Kang1,* [1] Department of Materials Science and Engineering, The new three-dimensional (3D) porous graphene-metal oxide Korea University, Republic of Korea. composite microspheres are prepared by a one-pot spray pyrolysis [2] Department of Chemical Engineering, Konkuk process. 3D porous SnO2-graphene microspheres selected as the first University, Republic of Korea. target material showed superior electrochemical properties as anode materials for lithium ion batteries. Discharge capacity of the 3D porous SnO2-graphene microspheres after 500 cycles at a high current density of 2 A g-1 is 1009 mA h g-1. Nano Research DOI (automatically inserted by the publisher) Review Article/Research Article Please choose one Three-Dimensional Porous Graphene-Metal Oxide Composite Microspheres: Preparation and Application in Li-Ion Batteries Seung Ho Choi1,2, Jung-Kul Lee2(), and Yun Chan Kang1() Received: day month year ABSTRACT Revised: day month year The use of new three-dimensional (3D) porous graphene-metal oxide composite microspheres that has been studied as anode material for lithium ion batteries (LIBs) is firstly introduced here. 3D graphene microspheres are aggregates of individual hollow graphene nanospheres composed of sheet graphene. Metal oxide nanocrystals are uniformly distributed over the graphene surface of the microspheres. The 3D porous graphene-SnO2 microspheres were selected as the first target material for investigation because of their superior electrochemical properties. The 3D porous graphene-SnO2 and graphene microspheres, and bare SnO2 powders, deliver discharge capacities of 1009, 196, and 52 mA h g-1, respectively, after 500 cycles at a current density of 2 A g-1. The 3D porous graphene-SnO2 microspheres have uniquely low charge transfer resistances and high lithium ion diffusivities before and after cycling. Accepted: day month year (automatically inserted by the publisher) © Tsinghua University Press and Springer-Verlag Berlin Heidelberg 2014 KEYWORDS Graphene • Metal oxide • Nanostructures • Electrode material• Batteries 1. Introduction Two-dimensional (2D) graphene-metal oxide phenomenon, but also introduces desirable composites with unique combinations of electronic, characteristics of fast ionic and electronic transport, chemical, and mechanical properties are considered high specific area and strong mechanical properties promising materials for various applications such [10-20]. as batteries, supercapacitors, sensors, and catalysts In energy storage fields, various 3D [1-9]. In continuous and large-scale production of graphene-metal oxide structures, such as porous 2D processes, graphene film, graphene foam, and graphene ball graphene-based composites are subject to serious hybrids, are more significant than the 2D forms. 3D aggregation between the graphene sheets owing to graphene structures maintain the superior intrinsic van der Waals forces [10-14]. A change to properties of graphene sheets, such as large surface material by liquid solution three-dimensional (3D)tographene from [email protected]; 2D graphene areas, Lee, novel physical properties and excellent Address correspondence Yun Chan Kang, Jung-Kul [email protected]. sheets is not only a good solution for aggregation electrochemical properties, and can further exhibit Nano Res. improved functions through addition of metal spherical hybrids remains a large and essential oxides [21-34]. For example, a 3D graphene challenge. In this study, we first synthesized the structure with porous morphology has many new structured 3D graphene-metal oxide spherical advantages such as easy electrolyte penetration and powders with macroporous structure for anode fast Li diffusion for lithium ion batteries [26-34]. applications Also, 3D graphene sheets with their outstanding microspheres are aggregates of individual hollow electrical conductivity and flexibility act as an graphene nanospheres formed by graphene sheets. excellent support, and as a buffer layer that Metal mitigates Li-ion distributed over the graphene sheets forming the insertion/extraction by absorption of stress, thus microspheres. The hollow graphene nanosphere improving the structural stability and cyclability of structure accommodates the volume change of electrode materials [26-34]. In particular, 3D metal oxides during repeated lithium insertion and graphene-metal extraction and prevents growth of active material + reported volume to changes oxide possess during composites excellent have been electrochemical properties through a range of energy storage applications [21-34]. Choice of graphene-metal a of oxide LIBs. 3D porous nanocrystals were graphene uniformly crystals during cycling. In this study, 3D graphene-SnO2 microspheres with porous structure were selected as the first synthesis target material because SnO2 nanostructured continuous, and large-scale production is extremely widely studied as anode materials for LIBs. important. In previous reports, 3D graphene-metal Polystyrene (PS) nanobeads were used as sacrificial oxide composite structures were mainly prepared templates in creating a porous structure [14,29]. 3D using a chemical vapor deposition (CVD) process or porous graphene-SnO2 composite microspheres a multistep solution process [15-18,35-39]. CVD showed high reversible capacity and excellent synthesized graphene-metal oxide is commonly cycling and fast rate performance. Our approach to grown on a flat metal foil or thin film greatly fabricating limiting its application in energy storage due to low powders may be valuable in developing this production yield [16-18]. Compared with the CVD application for energy storage devices. processes, for 3D materials with various morphologies have been solution architectures of facile, method, oxide method a 3D porous graphene structure including hydrothermal, self-assembly, and freeze-drying 2. Experimental techniques, are large scale and less costly, and the 2.1 resulting 3D graphene-metal oxide architectures composite microspheres. Synthesis of 3D porous graphene-SnO2 have desirable features of high porosity and pore Graphene oxide (GO) was synthesized using a structure with meso and macropores [35-39]. modified Hummer’s method [40]. 3D porous However, obstacles to use of the solution process graphene-SnO2 are the multiple steps, long reaction times, and use prepared by ultrasonic spray pyrolysis at 800 oC; a of a toxic reducing agent for graphene oxide schematic of the apparatus is shown in Figure S10. reduction [35-39]. As potential commercial products A quartz reactor of length 1200 mm and diameter 50 for industrial applications, 3D graphene-metal mm was used, with a nitrogen flow rate (carrier oxide spherical powders with regular morphology gas) of 10 L min-1. The as-obtained GO was and non-aggregating properties are attractive. redispersed in distilled water and exfoliated by Therefore, development of a new continuous and ultrasonication to generate GO sheets. 500 mL of the one-step process for 3D graphene-metal oxide exfoliated GO solution (1 mg ml-1) was added to 1.4 | www.editorialmanager.com/nare/default.asp microspheres were directly Nano Res. g of Sn oxalate (13 mM) in H2O2 solution. Then, 4.2 analysis of nitrogen adsorption measurements g of 100-nm PS nanobeads was added into the (TriStar 3000). The powders were also investigated solution of GO sheets and Sn. Subsequently, the using X-ray photoelectron spectroscopy (XPS), prepared PS (ESCALAB-210) with Al K radiation (1486.6 eV). nanobeads, and GO sheets was dispersed in Thermal gravimetric analysis (TGA, SDT Q600) was performed in air at a heating rate of 10°C min-1 to determine the amount of graphene in the composite microspheres. solution with Sn oxalate salt, distilled water by ultrasonication. 2.2 Characterizations The crystal structures of the powders were investigated by X-ray diffractometry (XRD), (X’pert 2.3 Electrochemical Measurements PRO MPD), using Cu Kradiation (= 1.5418 Å ). Capacities and cycling properties of the powders were determined using a 2032-type coin cell format. The electrode was prepared from a mixture containing 70 wt% of the active material, 15 wt% of Super P, and 15 wt% of sodium carboxymethyl cellulose (CMC) binder. Lithium metal and microporous polypropylene film were used as counter electrode and separator, respectively. The electrolyte was 1 M LiPF6 in a 1:1 mixture by volume of ethylene carbonate/dimethyl carbonate The morphological features were investigated using field-emission scanning electron microscopy (FE-SEM, Hitachi S-4800), and high-resolution transmission electron microscopy (HR-TEM, JEM-2100F), at a working voltage of 200 kV. The specific surface graphene-SnO2 areas composite of the 3D porous microspheres were calculated from a Brunauer–Emmett–Teller (BET) Scheme 1. Schematic diagram for the formation process of 3D porous graphene-SnO2 composite microsphere. (EC/DMC) with Charge-discharge were determined range 0.001–3.0 V 5% fluoroethylene carbonate. characteristics of the samples through cycling in the potential at various fixed current densities. www.theNanoResearch.com∣www.Springer.com/journal/12274 | Nano Research Nano Res. Cyclic voltammetry (CV) measurements were carried out at a scan rate of 0.1 mV s-1. Dimensions of the negative electrode were 1 cm × 1 cm and mass loading was approximately 1.2 mg cm-2. 3. Results and discussion 3D porous graphene-metal oxide composite microspheres were prepared by a one-pot spray pyrolysis process. The SnO2 nanocrystals of active material for lithium storage were distributed inside individual hollow graphene nanosphere consisting of graphene sheets. A schematic diagram for the formation of 3D porous SnO2-graphene microspheres by one-pot spray pyrolysis is shown in Scheme 1. Droplets containing PS nanobeads, fragments of graphene oxide sheets, and tin oxalate, were formed by an ultrasonic nebulizer. Drying these droplets produced the PS-tin oxalate-graphene oxide composite powder, in which PS nanobeads were uniformly distributed among the graphene oxide sheets and tin oxalate. Graphene oxide binds with PS nanobeads in water through a hydrophobic interaction [41,42]. In consequence, PS nanobeads improve the stability of a colloidal solution of graphene oxide sheets. Elimination of the PS nanobeads by thermal decomposition into CO2 and H2O resulted in 3D porous graphene microspheres with numerous tiny hollow individual nanospheres. Decomposition of tin oxalate and thermal reduction of graphene oxide sheets resulted in SnO2-graphene composite microsphere [40]. Overall, 3D porous SnO2-graphene microspheres were formed from single droplets by one-pot spray pyrolysis, where process conditions included a short residence time of 3 s in a hot wall reactor maintained at 800°C under a nitrogen atmosphere. Ultrafine SnO2 nanocrystals were uniformly distributed over the 3D porous graphene microspheres. The size of nanospheres making up a 3D porous microsphere could be easily manipulated by controlling the PS nanobeads’ size, Figure 1. Morphologies of the 3D porous graphene-SnO2 composite microspheres: a,b) SEM images, c-e) TEM images, f) SAED pattern, and g) elemental mapping images of Sn and C components. composite microspheres prepared by the one-pot spray pyrolysis method described above are shown in Figure 1. The concentration of tin oxalate was 13 mM. SEM images of the composite microspheres show an embossed structure, and TEM images show numerous tiny hollow graphene nanospheres. The high resolution TEM image shown in Figure 1e reveals graphene sheets with multiple layers forming the skin of individual graphene nanospheres. Ultrafine SnO2 nanocrystals of several nanometers in size were uniformly distributed over the graphene sheets, as shown in Figure 1e. The Figure S2 exhibits clear lattice fringes with d spacings of 0.34 nm and 0.26 nm, which can be attributed to the (110) and (101) planes of rutile SnO2, respectively [29]. The selected area electron diffraction (SAED) pattern of the composite powders as shown in Figure 1f shows the ring-like mode characteristic of polycrystalline SnO2 [43]. The elemental mapping images in Figure 1g show that the uniform distributions of the Sn and C components originated from the SnO2 nanocrystals as shown in Figure S1. Morphologies of the 3D porous SnO2-graphene and graphene sheets, respectively, uniformly | www.editorialmanager.com/nare/default.asp Nano Res. Figure 3. Morphologies and SAED pattern of the 3D porous graphene microspheres: a,b) SEM images, c,d) TEM images, and e) SAED pattern. SnO2-graphene composite microspheres. The high resolution TEM image in Figure 3d shows graphene sheets with multiple layers forming the skin of individual drupelets. The SAED pattern in Figure Figure 2. TEM images and elemental mapping images of the 3e shows sets of bright spots and faint spots, 3D porous graphene-SnO2 composite microspheres prepared indicating that the sample consists of randomly from spray solution with (a-d) low and (e-h) high concentration oriented graphene layers [44,45]. of Sn oxalate (8 mM and 18 mM): a-c) TEM images of low SnO2, d) elemental mapping images of low SnO2, e-g) TEM images of high SnO2, and h) elemental mapping images of high SnO2. Figure 4a shows the XRD patterns of both the 3D porous graphene and graphene-SnO2 microspheres prepared directly by spray pyrolysis at temperatures of 800 °C. The XRD pattern of the distributed over the 3D porous SnO2-graphene graphene composite diffraction peak around 23 microspheres. Figure 2 show the microspheres shows o a broadened similar to reduced morphologies and elemental mapping images of the graphene graphene-SnO2 composite microspheres prepared microspheres exhibits pure crystal structure of from the spray solutions with low (8 mM) and high rutile SnO2 (JCPDS card no. 41-1445) [46]. The mean (18 The crystallite size of SnO2 nanocrystals dispersed on graphene-SnO2 composite microspheres had 3D graphene microspheres calculated from the (110) porous of peak using Scherer’s formula was an ultrafine 4 nm. ultrafine SnO2 nanocrystals over the microspheres The pore-size distributions of the 3D porous regardless of SnO2 contents in the composite SnO2-graphene and graphene microspheres were powders. Morphologies of the 3D porous graphene investigated by nitrogen isothermal adsorption, and microspheres, not containing SnO2, prepared by the the results are shown in Figure 4b. Both samples one-pot spray pyrolysis method from a spray had similar pore size distributions, including both solution of PS nanobeads and graphene oxide sheets, mesopores (2–50 nm) and macropores. BET surface are shown in Figure 3. The graphene microspheres areas had microspheres were 120 and 200 m2 g-1, respectively. mM) concentrations structure similar and of tin uniform structure oxalate. distribution to the of oxide, the while the SnO2-graphene SnO2-graphene and www.theNanoResearch.com∣www.Springer.com/journal/12274 | Nano graphene Research Nano Res. thermal reduction of GO sheets containing oxygen functional groups into graphene occurred when the preparation temperature was set to 800 °C [47]. The overall XPS spectrum of the 3D porous SnO2-graphene microspheres (Figure S4) showed clear Sn 3d5/2 (487.3eV) and Sn 3d3/2 (495.8eV) peaks [48]. The electrochemical properties of the 3D porous SnO2-graphene microspheres were evaluated by assembling a coin-type half-cell. In addition, we tested electrochemical properties of 3D Figure 4. Properties of the 3D porous graphene and graphene-SnO2 composite porous microspheres: a) XRD patterns, b) pore size distributions, c) XPS spectrum of C1s of 3D SnO2 microspheres, both prepared by spray pyrolysis under composite microspheres. graphene microspheres without SnO2 nanocrystals, and porous graphene microspheres, and d) XPS spectrum of C1s of 3D porous graphene-SnO2 bare The graphene content in the 3D the same conditions; the bare SnO2 porous SnO2-graphene microspheres was evaluated to be microspheres had a spherical shape and dense 19.5 wt% by thermogravimetric analysis (Figure S3). structure as shown in Figure S5. Figure 5a shows Figures 4c and 4d show the XPS profiles of C1s the cyclic voltammogram (CV) curves for the first 5 acquired cycles from the 3D porous (Figure 4c) and graphene of the 3D porous SnO2-graphene porous microspheres at a scan rate of 0.1 mV s-1. In the first graphene-SnO2 microspheres (Figure 4d). The C1s cathodic step, the apparent reduction peak at 0.9 V peak in the XPS profile could be attributed to sp2 is attributed to form Li2O and Sn metal and solid bonded carbon (C–C), epoxy and alkoxy groups electrolyte interphase (SEI) layers when SnO2 (C–O) and carbonyl and carboxylic (C=O) groups, nanocrystals react with Li+ [48-54]. Low-potential which corresponded to peaks at 284.6, 286.6, and peaks (at < 0.6 V) corresponding to the Li xSn alloy 288.1 eV, respectively [47]. The XPS profiles showed formation sharp peaks at around 284.6 eV, which could be oxidation peaks at 0.25 V and 0.6 V during the assigned to graphitic carbon [47]. The relative anodic scan are related to dealloying of Li xSn carbon content of the sp2 bonded carbon at 286.4 eV [43,48-54]. In the second cycle, the decomposition was SnO2-graphene peak of SnO2 at 0.9 V disappeared and the related microspheres. The carbonyl and carboxylic (C=O) peaks of Li-Sn alloy and dealloying reactions were groups were not observed in the XPS C1s profile of seen repeatedly. Reduction peaks at 1.5 V in the first the graphene-SnO2 composite microspheres due to cathodic step were observed in the CV curves for the complete reduction of GO sheets into reduced 3D porous SnO2-graphene microspheres and 3D GO sheets. Analysis by XPS indicated that the porous graphene microspheres and the peaks microspheres 83% in the 3D porous 3D | www.editorialmanager.com/nare/default.asp are also observed [43,48-54]. The Nano Res. storage at highly active defect sites [49-52]. 3D porous SnO2-graphene microspheres delivered discharge and charge capacities of 1586 mA h g-1 and 1010 mA h g-1 in the first cycle, and the corresponding initial CE was 64%. Bare SnO2 delivered discharge and charge capacities of 1397 mA h g-1 and 935 mA h g-1 in the first cycle, Figure 5. Electrochemical properties of the 3D porous graphene and graphene-SnO2 composite microspheres and bare SnO2 powders: a) CV curves, b) initial charge/discharge curves at a current density of 2 A g-1, c) cycling performances at a current density of 2 A g-1, and d) rate performance and Coulombic efficiencies of 3D porous graphene-SnO2 composite microspheres. with of 67%. The irreversible capacity loss of the bare SnO2 powders attributed disappeared from the second cycles as shown in a corresponding initial CE to is the Figures 5a and S6. The reduction peak at 1.5 V in formation of Li2O from SnO2 and SEI layers at the the first cathodic step is attributable to irreversible electrode–electrolyte interface [43,48-54]. lithium insertion into graphene layers of the 3D Cycling performances of the 3D porous porous structure. Figure 5b shows the initial charge SnO2-graphene and graphene microspheres and and porous bare SnO2 powders at a constant current density of SnO2-graphene and graphene microspheres and discharge curves of the 3D 2 A g-1 are shown in Figure 5c. In comparison, after bare SnO2 powders. The operating cut-off voltages 500 cycles the 3D porous SnO2-graphene and were 0.001 and 3 V at a current density of 2 A g-1. graphene microspheres and bare SnO2 powders The initial discharging and charging specific delivered discharge capacities of 1009, 196, and 52 capacities of the 3D porous graphene microspheres mA h g-1, respectively, and the corresponding were 1244 and 389 mA h g , respectively. capacity retentions measured after the first cycles Coulombic were 96, 47, and 5%. Coulombic efficiency of 3D -1 efficiency (CE) of the graphene microspheres observed in the first cycle was low at porous 32%, which is an unavoidable phenomenon in approximately 99% after the tenth cycle and reduced graphene oxide materials SnO2-graphene microspheres reached [55,56]. remained at this value in subsequent cycles. The Electrochemical properties of reduced graphene average Coulombic efficiency from 100th to 500th oxide are affected by synthesis methods, and cycles of these SnO2-graphene microspheres was various lithium storage properties have been 99.8%. The increase in the discharge capacities of previously reported [6-8]. However, most reduced the 3D porous SnO2-graphene microspheres after graphene oxide has low initial CE due to the high 100 cycles had been attributed to the formation of a production of SEI layers resulting from the high gel-like reversible polymer film on the microsphere specific surface area and to irreversible lithium ion www.theNanoResearch.com∣www.Springer.com/journal/12274 | Nano Research Nano Res. surfaces [57-59]. The 3D porous SnO2-graphene good conductivity and morphological uniqueness composite excellent of of contribute microspheres electrochemical properties have regardless SnO2 3D porous to graphene-SnO2 their excellent were contents (see Figure S7a). The long-term cycling performance, and performance electrochemical impedance of 3D porous SnO2-graphene microspheres electrochemical confirmed by spectroscopy (EIS) microspheres at a high value of the current density, measurements. Nyquist plots of the electrodes 5 A g-1, is shown in Figure S7b. The 2nd and 1000th consisted of a semicircle in the medium frequency discharge porous region and an inclined line at low frequencies. The graphene-SnO2 microspheres were 905 and 730 mA medium-frequency semicircle was attributed to h g , and the Coulombic efficiency was reached at charge-transfer resistance between active material 99.7% after 50 cycles. The discharging and charging and electrolyte, and the low frequency portion of rate performance of the 3D porous graphene-SnO2 the trace corresponded to the lithium diffusion microspheres are shown in Figure 5d. As can be process within the electrodes [62-64]. The charge seen, the average reversible discharge capacities transfer resistance of 3D porous graphene-SnO2 were 1020, 875, 785, 716, and 660 mA h g at current microspheres was much smaller than that of bare densities of 1, 3, 5, 7, and 9 A g -1, respectively. After SnO2 powders before cycling, as shown in Figure high-rate discharge S9a. Figure S9b shows the relationship between the capacity recovered to a value as high as 941 mA h real part of the impedance spectrum Zre and ω-1/2 g-1 for a lower current density of 1 A g-1. (where ω = 2πf is angular frequency) in the capacities of the 3D -1 -1 charge-discharge cycling, TEM images as shown in Figure S8 showed that low-frequency region, before cycling. The gradual 3D porous graphene-SnO2 microspheres maintained low-frequency slope (the Warburg impedance their overall morphology after cycling, but bare coefficient) of Zre versus ω-1/2 indicates high lithium SnO2 powders lost their original morphologies after ion diffusivity for 3D porous graphene-SnO2 the 200th cycle. The 3D graphene backbone of the microspheres [63,64]. The unique structure of 3D graphene-SnO2 microspheres was maintained, as porous graphene-SnO2 microspheres resulted in shown in the TEM images. The Sn component low charge transfer resistance and high lithium ion remained dispersed over the diffusivity. Figures S9c and S9d show the Nyquist aggregation even after plot and the Zre - ω-1/2 relationship after 200 cycles. cycling, as shown in the elemental mapping images The microspheres continued to have low charge in Figure S8b. The 3D porous graphene structure transfer resistance and high lithium ion diffusivity suppressed the aggregation of SnO2 nanocrystals even after 200 cycles. On the other hand, the charge during repeated cycling. The graphene increases the transfer resistance of bare SnO2 powders increased electrical conductivity of the electrode and is able to after accommodate the strain induced by volume change performance of SnO2. It also facilitated fast transportation of microspheres is due to their structural stability and electrons and lithium ions, which is responsible for graphene’s synergy effects. uniformly microspheres without cycling. The of excellent electrochemical porous graphene-SnO2 3D the good cycling stability and rate capability [59-61]. On the other hand, changes in the bare SnO2 4. Concluisons powders caused disconnection between active material, conducting carbon, and copper foil, In this study, electrochemical properties of 3D porous resulting in rapid capacity fading upon cycling. The graphene-SnO2 microspheres were compared with | www.editorialmanager.com/nare/default.asp Nano Res. those of 3D porous graphene microspheres (without of the bare SnO2 powders, CV curves of the 3D SnO2) and bare SnO2 powders, prepared by the same porous graphene, Cycling performances of the 3D process. 3D porous graphene-SnO2 microspheres porous graphene-SnO2 composite, TEM images of the were formed from single droplets using the one-pot porous graphene-SnO2 composite after cycling, EIS spray pyrolysis method. Ultrafine SnO2 nanocrystals data of the 3D porous graphene-SnO2 composite and were found to be uniformly distributed within the the bare SnO2, Schematic diagram of spray pyrolysis individual graphene nanospheres, which consisted of process, TEM image of the 3D porous graphene-SnO2 graphene layers. The size of individual graphene composite microspheres prepared using 40-nm PS nanospheres forming the 3D porous microspheres, nanobeads, SEM image of the crushed 3D porous and the content of SnO2 active material, were easily graphene-SnO2 composite microspheres) is available controlled through the size of polystyrene (PS) in nanobeads used as sacrificial templates, and the http://dx.doi.org/10.1007/s12274-***-****-* concentration of tin salt dissolved in the spray (automatically inserted by the publisher). solution, respectively. 3D porous graphene-SnO2 composite microspheres showed high reversible capacity and good cycling performance at high current density. morphological The good conductivity uniqueness of 3D and porous graphene-SnO2 microspheres contribute to excellent electrochemical performance. The process developed here could be applied in the preparation of various types of 3D porous graphene-metal oxide composite microspheres for a wide range of applications, including energy storage devices. the online version of this article at References [1] Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J. W.; Potts, J. R.; Ruoff, R. S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [2] Huang, X.; Zeng, Z.; Fan, Z.; Liu, J.; Zhang, H. Graphene-Based Electrodes. Adv. Mater. 2012, 24, 5979–6004. [3] Guo, S. J.; Dong, S. J. Graphene Nanosheet: Synthesis, Molecular Engineering, Thin Film, Hybrids, and Energy and Analytical Applications. Chem. Soc. Rev. 2011, 40, 2644–2672. [4] Liu, Y. X.; Dong, X. C.; Chen, P. Biological and Chemical Sensors based on Graphene Materials. Chem. Soc. Rev. 2012, 41, 2283–2307. Acknowledgements [5] Jiang, J.; Li, Y. Y.; Liu, J. P.; Huang, X. T.; Yuan, C. Z.; Lou, This work was supported by the National Research X. W. Recent Advances in Metal Oxide-based Electrode Foundation of Korea (NRF) grant funded by the Architecture Design for Electrochemical Energy Storage. Adv. Korea Mater. 2012, 24, 5166–5180. government (MEST) (No. 2012R1A2A2A02046367). This work was supported [6] Wu, Z. S.; Zhou, G. M.; Yin, L. C.; Ren, W. C.; Li, F.; Cheng, by the Energy Efficiency & Resources Core H. M. Graphene/Metal Oxide Composite Electrode Materials for Technology Program of the Korea Institute of Energy Storage. Nano Energy 2012, 1, 107–131. Energy Planning [7] Huang, X.; Tan, C. L.; Yin, Z. Y.; Zhang, H. 25th Anniversary (KETEP), granted financial resource from the Article: Hybrid Nanostructures Based on Two-Dimensional Ministry of Trade, Industry & Energy, Republic of Nanomaterials. Adv. Mater. 2014, 26, 2185–2204. Technology Evaluation and Korea (201320200000420). [8] Armstrong, M. J.; O’Dwyer, C.; Macklin, W. J.; Holmes, J. D. Evaluating the Performance of Nanostructured Materials as Electronic Supplementary Material: Supplementary Lithium-Ion Battery Electrodes. Nano Res. 2014, 7, 1-62. material (Schematic diagrams of 3D graphene, [9] Leng, K.; Zhang, F.; Zhang, L.; Zhang, T.; Wu, Y.; Lu, Y.; HR-TEM, TG, and XPS data of the 3D porous Huang, graphene-SnO2 composite microsphere, SEM image Supercapacitors with Ultrahigh Performance. Nano Res. 2013, Y.; Chen, Y. Graphene-Based Li-Ion www.theNanoResearch.com∣www.Springer.com/journal/12274 | Nano Hybrid Research Nano Res. 6, 581–592. Graphene/MnO2 Composite Networks As Ultralight and Flexible [10] Supercapacitor Electrodes. ACS Nano 2013, 7, 174–182. Huang, X.; Qian, K.; Yang, J.; Zhang, J.; Li, L.; Yu, C.; Zhao, D. Functional Nanoporous Graphene Foams with [22] Cao, X.; Yin, Z.; Zhang, H. Three-Dimensional Graphene Controlled Pore Sizes. Adv. Mater. 2012, 24, 4419–4423. Materials: [11] Supercapacitors. Energy Environ. Sci. 2014, 7, 1850–1865. Luo, J.; Jang, H. D.; Sun, T.; Xiao, L.; He, Z.; Katsoulidis, Preparation, Structures and Application in A. P.; Kanatzidis, M. G.; Gibson, J. M.; Huang, J. X. [23] Dong, X. C.; Cao, Y. F.; Wang, J.; Park, M. B. C.; Wang, L. Compression and Aggregation-Resistant Particles of Crumpled H.; Huang, W.; Chen, P. Hybrid Structure of Zinc Oxide Soft Sheets. ACS Nano 2011, 5, 8943–8949. Nanorods [12] Mao, S.; Wen, Z. H.; Kim, H. J.; Lu, G. H.; Hurley, P.; Chen, Supercapacitor and Electrochemical Sensor Applications. RSC J. H. A General Approach to One-Pot Fabrication of Crumpled Adv. 2012, 2, 4364–4369. Graphene-Based Nanohybrids for Energy Applications. ACS [24] Wang, X. B.; Zhang, Y. J.; Zhi, C. Y.; Wang, X.; Tang, D. M.; Nano 2012, 6, 7505–7513. Xu, Y. B.; Weng, Q. H.; Jiang, X. F.; Mitome, M.; Golberg, D.; [13] Chen, Y.; Guo, F.; Jachak, A.; Kim, S. P;. Datta, D.; Liu, J.; Bando, Y. Three-Dimensional Strutted Graphene Grown by Kulaots, I.; Vaslet, C.; Jang, H. D.; Huang, J.; Kane, A.; Shenoy, Substrate-Free V. B.; Hurt, R. H. Aerosol Synthesis of Cargo-Filled Graphene Supercapacitors. Nat. Comm. 2013, 4, 2905. Nanosacks. Nano Lett. 2012, 12, 1996–2002. [25] Xu, Z. W.; Li, Z.; Holt, C. M. B.; Tan, X. H.; Wang, H. L.; [14] Choi, B. G.; Yang, M. H.; Hong, W. H.; Choi, J. W.; Huh, Y. Amirkhiz, B. S.; Stephenson, T.; Mitlin, D. Electrochemical S. 3D Macroporous Graphene Frameworks for Supercapacitors Supercapacitor with High Energy and Power Densities. ACS Nano 2012, 6, Nanoarchitectures with Ultrahigh Power Density. J. Phys. Chem. 4020–4028. Lett. 2012, 3, 2928–2933. [15] Chen, Z. P.; Ren, W. C.; Gao, L. B.; Liu, B. L.; Pei, S. F.; [26] Wei, W.; Yang, S. B.; Zhou, H. X.; Lieberwirth, I.; Feng, X. Cheng, H. M. Three-Dimensional Flexible and Conductive L.; Müllen, K. 3D Graphene Foams Cross-linked with Interconnected Graphene Networks Grown by Chemical Vapour Pre-encapsulated Fe3O4 Nanospheres for Enhanced Lithium Deposition. Nat. Mater. 2011, 10, 424–428. Storage. Adv. Mater. 2013, 25, 2909–2914. [16] Li, C.; Shi, G. Q. Three-Dimensional Graphene and Three Sugar Dimensional Blowing Electrodes from Graphene for Foam for High-Power-Density Sponge-like Graphene [27] Luo, J. S.; Liu, J. L.; Zeng, Z. Y.; Ng, C. F.; Ma, L. J.; Zhang, Architectures. Nanoscale 2012, 4, 5549–5563. H.; Lin, J. Y.; Shen, Z. X.; Fan, H. J. Three-Dimensional [17] Cao, X. H.; Shi, Y. M.; Shi, W. H.; Lu, G.; Huang, X.; Yan, Graphene Foam Supported Fe3O4 Lithium Battery Anodes with Q. Y.; Zhang, Q. C.; Zhang, H. Preparation of Novel 3D Long Cycle Life and High Rate Capability. Nano Lett. 2013, 13, Graphene Networks for Supercapacitor Applications. Small 2011, 6136–6143. 7, 3163–3168. [28] Cao, X. H.; Shi, Y. M.; Shi, W. H.; Rui, X. H.; Yan, Q. Y.; [18] Yoon, J. C.; Lee, J. S.; Kim, S. I.; Kim, K. H.; Jang, J. H. Kong, Three-Dimensional Graphene Nano-Networks with High Quality Three-Dimensional Graphene Networks for High-Performance and Mass Production Capability via Precursor-Assisted Chemical Anode Material in Lithium-Ion Batteries. Small 2013, 9, Vapor Deposition. Sci. Rep. 2013, 3, 1788. 3433–3438. [19] Xie, X.; Yu, G.; Liu, N.; Bao, Z.; Criddle, C. S.; Cui, Y. [29] Huang, X.; Yu, H.; Chen, J.; Lu, Z. Y.; Yazami, R.; Hng, H. Graphene–Sponges as High-Performance Low-Cost Anodes for H. Ultrahigh Rate Capabilities of Lithium-Ion Batteries from 3D Microbial Fuel Cells. Energy Environ. Sci. 2012, 5, 6862–6866. Ordered Hierarchically Porous Electrodes with Entrapped Active [20] Sohn, K.; Na, Y. J.; Chang, H.; Roh, K. M.; Jang, H. D.; Nanoparticles Configuration. Adv. Mater. 2014, 26, 1296–1303. Huang, J. Oil Absorbing Graphene Capsules by Capillary [30] Liu, X.; Cheng, J.; Li, W.; Zhong, X.; Yang, Z.; Gu, L.; Yu, Molding. Chem. Commun. 2012, 8, 5968–5970. Y. Superior Lithium Storage in a 3D Macroporous Graphene [21] He, Y.; Chen, W. J.; Li, X. D.; Zhang, Z. X.; Fu, J. C.; Zhao, Framework/SnO2 C. 7817–7822. H.; Xie, E. Q. Freestanding Three-Dimensional | www.editorialmanager.com/nare/default.asp J.; Zhang, H. Preparation Nanocomposite. of Nanoscale MoS2-Coated 2014, 6, Nano Res. [31] Zhu, J. X.; Yang, D.; Rui, X. H.; Sim, D. H.; Yu, H.; Hng, H. Microsphere/Reduced Graphene Oxide/Ag Composite. J. Colloid H.; Hoster, H. E.; Ajayan, P. M.; Yan, Q. Y. Facile Preparation of Interface Sci. 2013, 402, 279–283. Ordered Binder-Free [42] Zhang, W. L.; Liu, Y. D.; Choi, H. J. Graphene Oxide Electrodes with High Li Storage Performance. Small 2013, 9, Coated Core–Shell Structured Polystyrene Microspheres and 3390–3397. Their Electrorheological Characteristics under Applied Electric [32] Cao, X. H.; Zheng, B.; Rui, X. H.; Shi, W. H.; Yan, Q. Y.; Field. J. Mater. Chem. 2011, 21, 6916–6921. Zhang, H. Metal Oxide-Coated Three-Dimensional Graphene [43] Zhou, X.; Wan, L. J.; Guo, Y. G. Binding SnO2 Nanocrystals Prepared by the Use of Metal–Organic Frameworks as Precursors. in Nitrogen-Doped Graphene Sheets as Anode Materials for Angew. Chem. Int. Ed. 2014, 53, 1404–1409. Lithium-Ion Batteries. Adv. Mater. 2013, 25, 2152–2157. [33] Ji, J. Y.; Ji, H. X.; Zhang, L. L.; Zhao, X.; Bai, X.; Fan, X. B.; [44] Stankovich, S.; Dikin, D. A.; Dommett, G. H. B.; Kohlhaas, Zhang, F. B.; Ruoff, R. S. Graphene-Encapsulated Si on K. M.; Zimney, E. J.; Stach, E. A.; Piner, R. D.; Nguyen, S. B. T.; Ultrathin-Graphite Ruoff, R. S. Graphene-based Composite Materials. Nature 2006, Porous Graphene–Metal Foam as Oxide@C Anode for High Capacity Lithium-Ion Batteries. Adv. Mater. 2013, 25, 4673–4677. 442, 282–286. [34] Li, N.; Chen, Z. P.; Ren, W. C.; Li, F.; Cheng, H. M. Flexible [45] Kim, T. Y.; Kang, H. C.; Tung, T. T.; Lee, J. D.; Kim, H. K.; Graphene-based Lithium Ion Batteries with Ultrafast Charge and Yang, W. S.; Yoon, H. G.; Suh, K. S. Ionic Liquid-Assisted Discharge Rates. PNAS 2012, 109, 17360–17365. Microwave Reduction of Graphite Oxide for Supercapacitors. [35] Gong, Y. J.; Yang, S. B.; Liu, Z.; Ma, L. L.; Vajtai, R.; RSC Adv. 2012, 2, 8808–8812. Ajayan, P. M. Graphene-Network-Backboned Architectures for [46] Seema, H.; Kemp, K. C.; Chandra, V.; Kim, K. S. High-Performance Lithium Storage. Adv. Mater. 2013, 25, Graphene–SnO2 Composites for Highly Efficient Photocatalytic 3979–3984. Degradation of Methylene Blue under Sunlight. Nanotechnology [36] Chen, W. F.; Li, S. R.; Chen, C. H.; Yan, L. F. Self-Assembly 2012, 23, 355705. and Embedding of Nanoparticles by In Situ Reduced Graphene [47] Beidaghi, M.; Wang, C. Micro-Supercapacitors Based on for Preparation of a 3D Graphene/Nanoparticle Aerogel. Adv. Interdigital Electrodes of Reduced Graphene Oxide and Carbon Mater. 2011, 23, 5679–5683. Nanotube [37] Huang, X. D.; Sun, B.; Chen, S. Q.; Wang, G. X. Performance. Adv. Funct. Mater. 2012, 22, 4501–4510. Self-Assembling [48] Li, Y. M.; Lv, X. J.; Lu, J.; Li, J. H. Preparation of Synthesis Graphene–Transition-Metal of Oxide Free-standing Flexible Nanoporous Electrodes Composites with Ultrahigh Power Handling for SnO2-Nanocrystal/Graphene-Nanosheets Composites and Their High-Performance Lithium-Ion Batteries and Supercapacitors. Lithium Storage Ability. J. Phys. Chem. C 2010, 114, Chem. Asian J. 2014, 9, 206–211. 21770–21774. [38] Xiao, L.; Wu, D. Q.; Han, S.; Huang, Y. S.; Li, S.; He, M. Z.; [49] Li, L.; Kovalchuk, A.; Tour, J. M. SnO2–Reduced Graphene Zhang, F.; Feng, X. L. Self-Assembled Fe2O3/Graphene Aerogel Oxide Nanoribbons as Anodes for Lithium Ion Batteries with with High Lithium Storage Performance. ACS Appl. Mater. Enhanced Cycling Stability. Nano Res. 2014, 7, 1319–1326. Interfaces 2013, 5, 3764–3769. [50] Lin, J.; Peng, Z. W.; Xiang, C. S.; Ruan, G. D.; Yan, Z.; [39] Nardecchia, S.; Carriazo, D.; Ferrer, M. L.; Gutiérrez, M. C.; Natelson, Monte, F. Three Dimensional Macroporous Architectures and Nanostructured SnO2 Composite Anodes for Lithium Ion Aerogels Built of Carbon Nanotubes and/or Graphene:Synthesis Batteries. ACS Nano 2013, 7, 6001–6006. and Applications. Chem. Soc. Rev. 2013, 42, 794–830. [51] Zhang, C. F.; Peng, X.; Guo, Z. P.; Cai, C. B.; Chen, Z. X.; [40] Choi, S. H.; Kang, Y. C. Crumpled Graphene–Molybdenum Wexler, D.; Li, S.; Liu, H. K. Carbon-Coated SnO2/Graphene Oxide Composite Powders: Preparation and Application in Nanosheets as Highly Reversible Anode Materials for Lithium Lithium-Ion Batteries. ChemSusChem 2014, 7, 523–529. Ion Batteries. Carbon 2012, 50, 1897–1903. [41] Zhang, T. Y.; Li, X. Q.; Kang, S. Z.; Qin, L. X.; Yan, W. F.; [52] Huang, Y.; Wu, D.; Wang, J.; Han, S.; Lv, L.; Zhang, F.; Mua, J. Facile Assembly and Properties of Polystyrene Feng, X. Amphiphilic Polymer Promoted Assembly of D.; Tour, J. M. Graphene Nanoribbon www.theNanoResearch.com∣www.Springer.com/journal/12274 | Nano and Research Nano Res. Macroporous Graphene/SnO2 Frameworks with Tunable 3214–3223. Porosity for High-Performance Lithium Storage. Small 2014, [62] Choi, S. H.; Kang, Y. C. Yolk–Shell, Hollow, and 10, 2226–2232. Single-Crystalline ZnCo2O4 Powders: Preparation Using a [53] Lee, C. W.; Seo, S. D.; Kim, D. W.; Park, S.; Jin, K.; Kim, Simple One-Pot Process and Application in Lithium-Ion Batteries. D. W.; Hong, K. S. Heteroepitaxial Growth of ZnO Nanosheet ChemSusChem 2013, 6, 2111–2116. Bands on ZnCo2O4 Submicron Rods Toward High-Performance [63] Park, M. S.; Kang, Y. M.; Wang, G. X.; Dou, S. X.; Liu, H. Li Ion Battery Electrodes. Nano Res. 2013, 6, 348–355. K. [54] Lee, C. W.; Seo, S. D.; Kim, D. W.; Park, S.; Jin, K.; Kim, Electrochemical Properties of SnO2 Nanomaterials. Adv. Funct. D. W.; Hong, K. S. Heteroepitaxial Growth of ZnO Nanosheet Mater. 2008, 18, 455–461. Bands on ZnCo2O4 Submicron Rods Toward High-Performance [64] Ko, Y. N.; Park, S. B.; Jung, K. Y.; Kang, Y. C. One-Pot Li Ion Battery Electrodes. Nano Res. 2013, 6, 348-355. Facile Synthesis of Ant-Cave-Structured Metal Oxide−Carbon [55] Xiang, H. F.; Li, Z. D.; Xie, K.; Jiang, J. Z.; Chen, J. J.; Microballs by Continuous Process for Use as Anode Materials in Lian, P. C.; Wu, J. S.; Yud, Y.; Wang, H. H. Graphene Sheets as Li-Ion Batteries. Nano Lett. 2013, 13, 5462–5466. The Anode Materials for Li-Ion Batteries: Preparation, Structure, Electrochemical Properties and Mechanism for Lithium Storage. RSC Adv. 2012, 2, 6792–6799. [56] Yang, J.; Liao, Q.; Zhou, X.; Liu, X.; Tang, J. Efficient Synthesis of Graphene-based Powder via in Situ Spray Pyrolysis and Its Application in Lithium Ion Batteries. RSC Adv. 2013, 3, 16449–16455. [57] Li, S.; Li, A.; Zhang, R.; He, Y.; Zhai, Y.; Xu, L. Hierarchical Porous Metal Ferrite Ball-In-Ball Hollow Spheres: General Synthesis, Formation Mechanism, and High Performance as Anode Materials for Li-Ion Batteries. Nano Res. 2014, 7, 1116–1127. [58] Choi, S. H.; Kang, Y. C. Using Simple Spray Pyrolysis to Prepare Yolk–Shell-Structured ZnO–Mn3O4 Systems with the Optimum Composition for Superior Electrochemical Properties. Chem. Eur. J. 2014, 20, 3014–3018. [59] Wang, D.; Yang, J.; Li, X.; Geng, D.; Li, R.; Cai, M.; Sham, T. K.; Sun, X. Layer by Layer Assembly of Sandwiched Graphene/SnO2 Nanorod/Carbon Nanostructures with Ultrahigh Lithium Ion Storage Properties. Energy Environ. Sci. 2013, 6, 2900–2906. [60] Wang, D.; Li, X.; Wang, J.; Yang, J.; Geng, D.; Li, R.; Cai, M.; Sham, T. K.; Sun, X. Defect-Rich Crystalline SnO2 Immobilized on Graphene Nanosheets with Enhanced Cycle Performance for Li Ion Batteries. J. Phys. Chem. C 2012, 116, 22149–22156. [61] Zhou, G.; Wang, D. W.; Yin, L. C.; Li, N.; Li, F.; Cheng, H. M. Oxygen Bridges between NiO Nanosheets and Graphene for Improvement of Lithium Storage. ACS Nano 2012, 6, | www.editorialmanager.com/nare/default.asp Effect of Morphological Modification on the

© Copyright 2026