THERMAL MODELS FOR PHOTOVOLTAIC

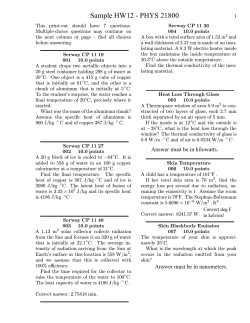

THERMAL MODELS FOR PHOTOVOLTAIC MODULES IN THE BIPV APPLICATIONS G.M. Tina Department of Electric, Electronic and Systemistic Engineering – University of Catania Viale A. Doria 6, 95125 Catania - Italy G. Notton ‘Systèmes Physiques de l’Environnement’ Laboratory, University of Corsica, UMR CNRS 6134, Route des Sanguinaires, F-20000 Ajaccio, France ABSTRACT: The operation temperature of photovoltaic (PV) modules changes constantly with the ambient variables (temperature, irradiance, wind speed and direction) as well as electrical operation point. In literature many papers describe models which estimate PV module temperature as a static one and on hourly time base but, in this paper, in order to establish a suitable model to monitor the temperature in a shorter time interval (i.e. a few minutes), a comparison among three dynamic models have been carried out. In these models many parameters have to be fixed starting from both manufacturer data and experimental tests. Numerical and experimental results, reported in this paper, refer to a semi-transparent PV module, where some thermal sensors are installed. This type of PV module is widely used as facades, roof or shading devices in office and commercial buildings. Keywords: Photovoltaic module, thermal model, efficiency 1 INTRODUCTION Photovoltaic (PV) systems are becoming larger and more diffused. Nowadays different solutions are technically and economically feasible such as building integrated photovoltaic systems (BIPVs) and concentrating PV systems. In these systems the PV cell temperature can be a critical variable. Moreover, it is well known that most of the solar radiation absorbed by a PV module is not converted to electricity but contributes to increasing the temperature of the module, thus reducing its electrical efficiency. However, there are special systems called hybrid Photovoltaic - Thermal (PV/T) collectors where the thermal energy produced by the PV cells is used to produce either hot water or hot air [1]. To predict the energy production of PV modules, it is necessary to evaluate the module temperature as a function of environmental variables. Studies show that there are many methods to calculate the module temperature: in [2] the method is based on a simple energy balance, where there is a parameter (empirically determined) that depends on the wind speed, in [3] starting from the temperature measured in the back of the PV module, the method determines an expression to calculate the cell temperature. The most well-known method is based on the knowledge of NOCT (Normal Operating Cell Temperature), that is provided by the PV module manufacturers. But this simple method is the most approximate, especially if the operating temperature of free-standing PV arrays is predicted as it is a straight proportion between the ∆T (cell temperature minus ambient temperature) and G (irradiance) and it does not take into account the real ventilation of the PV modules. The simplifying hypothesis assumed in the NOCT methodology, seems at first prohibitive for the use in the BIPV modelling/design area. In other models ([4], [5], [6], [7]) the panel is considered formed by a single layer, so one equation to describe it is used, whereas in [8] and [9], the PV panel is divided into horizontal sections and an equation of the thermal balance is written for each layer. When evaluating the efficiency of a PV system, the temperature variations are often regarded as instantaneous or use hourly steady state models. However, the changes in temperature due to varying solar radiation levels do not occur immediately. The PV module heats up and cools down gradually from step changes in solar radiation changes, following an exponential response. If the power output from PV module is modeled in short time periods, for example, on a minute by minute basis, the temperature response becomes considerably more important compared to the period of interest. In this context, it is crucial to determine the thermal time constant of a PV module (i.e. the time taken for the panel temperature to reach 63% of the total change in temperature in response to a step change in the solar radiation). It ranges roughly from 5 min to 15 min, depending on the PV composition and mounting arrangements. In order to develop a suitable multi layer thermal model of PV modules that can be used in BIPV applications, and in particular to on-line applications (e.g. monitoring or diagnostic), a comparison between three models of the literature ([8]÷[10]) is reported. 2 THERMAL MODELS OF PV MODULES Normally a PV module is encased in glass, the entire ensemble consists of five mediums: glass, resin, silicon, resin and glass. However, as the optical and thermal properties of glass and resin are almost identical and the thickness of the resin is very small, only three mediums must be considered, glass, silicon and glass. The following three isothermal regions are considered (see Fig. 1): front (glass), central (silicon) and the rear one (glass) Back Glass (bg) EVA Glass Fibre Cells (PV) EVA Front Glass (fg) Figure 1 Layers of a PV module with the correspondent subscripts. Some common hypothesis are considered in the following models: - The exchanges heat from the sides of the photovoltaic module are negligible (this assumption may be less true in the case of modules with aluminum frame, it is very realistic in the case of panel without frame). - All of the thermal materials properties considered homogeneous, are independent of temperature. - The part of solar radiation that is not converted into electrical energy is absorbed by cells as heat. - The thermal exchange among cells and EVA are negligible. - The ambient temperature is postulated as equal on all sides of the module. The models consider each layer as a homogenous slab, thus in the layer which contains both PV cell and glass fiber (see Fig. 1), calculation is carried out assuming it as a layer of PV cell. However, it is clear that PV cell and glass do not have the same thermal behaviour. Thus, this difference is accounted for in the models by adjustment of the radiation absorption/transmission factor of the layer according to the percentage area of PV cell and fiber glass. Verification with field measurement data proved it is a sufficient representation of the actual thermal behaviour of a semi-transparent PV panel [9]. The considered models are one-dimensional they are made of a serial assembling of one-dimensional elementary models, which explains the essential thermal transfers. In fact, for each layer just one temperature is assigned, so distribution of the temperature along the three dimensions of the module is neglected. A more detailed model is reported in [9], where the heat balance at the centre of each layer is calculated. The thermal mechanisms of a PV panel can be considered in terms of their electrical equivalents by correlating the electrical resistance and capacitance to the thermal resistance qTh and thermal capacitance CTh. The heat balance at each node is equivalent to a current Kirchhoff law. The equivalent circuit is reported in Fig. 2, where both current and voltage ideal generators are reported. The resistances determine the thermal steady state answer of the PV module, whereas the capacitances, together with resistances, intervene during the transients. Using the electrical circuit, five equations can be written at the corresponding nodes: T’fg (outside surface of front glass), Tfg (internal temperature of front glass), TPV (temperature of central layer, Tbg (internal temperature of back glass), T’bg (external temperature of back glass), whereas a circuit, made up of three nodes is used in [8] and [10] (see Fig. 3). Figure 2 five nodes equivalent electrical circuit of a PV module Tsky Tgro qr,fg,sky qr,fg,gr Tfg qcd,fg Ta qconv,fg Cfg qcd,PV TPV 1 2 CPV qcd,bg Cbg Tbg qr,bg,sky qr,bg,gr Tsky Tgro qconv,bg Ta Figure 3: three nodes equivalent electrical circuit of a PV module Actually the voltage generator “Tsky” (temperature of the atmospheric filter) is complex and rarely available, several expressions allows to calculate this temperature depending on Ta and other atmospheric variables (air pressure and humidity) [8]. It was made a comparison between three models in literature [8 ], [9] and [10]. In particular the model reported in [10], has been improved with the introduction of the thermal capacities of the module. The symbols used in the equations are different in the three references, so they have be changed into the corresponding ones used in [8]. So the set of equations is the following: εg J 1+ cos β 1− cos β 1+ cos β 1− cos β +εg Jg ≅ εg J +ε g J = εg J 2 2 2 2 (4) Where J g : ground-emitted longwave radiation, (1) (2) Jg is assumed as equal to J. εg is the glass emissivity The expression in the parenthesis accounts for correction factor of outdoor long-wave radiation absorption in a sloped panel. The first phrase shows absorption of the downwards longwave radiation while the second phrase (3) Each equation has been normalized respect with the Surface of layer that in this case, of course, are equal. On the other hand, it is worth noticing that the current “Φ2” has to be calculated considering that the global photovoltaic surface is smaller than the surface of the module. The studied models present many differences in the expressions of the coefficients of the set of first order differential equations; in particular the coefficients that model the convective heat transfer from the PV panel surface show the most important differences. Generally, in the literature, we note a wide discrepancy in the value taken for the convective coefficient [11]. In the following some other differences concerning the radiative coefficients and the flux received per unit area by the PV cells are described. 2.1 frontal layer In the frontal layer, the main differences among the studied models are about the radiative terms, the correspondent terms are reported in Table 1. Table 1 thermal balance of frontal layer: radiative terms shows absorption of the ground-emitted longwave radiation, though essentially it adds up to 1. It means that the radiative term between front glass and ground is included in (4) J, i.e. the atmospheric radiation, is a long wave radiation emitted by the atmosphere with an almost constant amount throughout the day. It does not contribute to PV power generation but it heats up the panel, thus it is included in the thermal equilibrium. Moreover, it is a measured entity given in the weather data, thus we do not need to calculate it from the sky temperature or other weather data. The amount of thermal radiation from the PV panel only depends on its temperature and emissivity, but not on the surrounding temperature so the sky temperature is not included in the equation. [10]: the radiative term between front glass and ground does not appear because the experiments were ran with the PV module in a horizontal position, but it was also neglected because not only the difference of temperature between front glass and ground normally is small but also the optimal tilt angle of the modules in the regions where the yearly solar radiation is high enough the tilt angle ranges from 0 (equator) to 35-40 ° (mid latitude) so the configuration factor between the front glass and cover and the ground ranges from 0 to 0.3. Also the configuration factors do not appear. 2.2 Central layer In central layer the main difference is into the energy flux Φ2 on the photovoltaic cells (i.e. the current generator in figures 2 and 3). The correspondent terms are reported in Table 2 [8] Not [9] present Table 2 Thermal balance of central layer [8] [9] [10] qr , fg , sky = 4 σ ⋅ ε g ⋅ (Tfg4 − Tsky ) Tfg − Ta Not [10] present Some remarks about the expressions reported in Table 1 are reported: [9]: Concerning the radiative component it is made of two terms. The first one assumes the following expression, where the two configuration factors appear: 2.3 Rear layer In the rear layer, the main differences among the studied models are about the radiative terms, the correspondent terms are reported in Table 3 experimental ones. The model [9] underestimates the PV module temperatures. Table 3 Thermal balance of the rear layer [8] [9] 45 Not present model [8] model [9] model [10] measurements 40 Not present [10] Not present 35 T P V [ °C ] 30 3. VALIDATION OF THE MODELING 25 20 The photovoltaic module tested is a Photowatt PWX 500 using multi-crystalline technology with a thickness of 0.2 mm. The encapsulation of cells is made between two sheets of tempered glass with high transmittance. The dimension of the module is 1042 mm · 462 mm · 39 mm. The peak power at a junction temperature equal to 25 °C is 49 W at ±10% the electrical efficiency for this module is equal to ηref = 0.13 at 25 °C and this reference for the efficiency will be used to calculate the electrical production of the PV module. Eight thermal sensors have been integrated into the module during its manufacturing: the first one measures the temperature on the back surface of the glass cover, another one measures the temperature on the back surface of the module and six other sensors measure the temperature on six points on the back surfaces of cells [8]. The evolution and of the other environmental parameters: solar irradiance in the plane of the panel, ambient temperature and wind speed are plotted in Fig. 5, whereas the front and back glass temperatures, and the cells temperature are in Fig. 6. 100 15 10 5 0 0.5 1 1.5 Time [sec] 2 2.5 3 4 x 10 Figure 7: Evolution of the central layer: mathematical models and measurements 4. CONCLUSIONS AND PERSPECTIVES This paper presented three thermal models available in the literature to describe the behaviour of the PV cell temperature. Two models [8] and [10] give similar results in good accordance with experimental data although the assumptions used in these models are different. Such modelling is very useful to predict the productivity of PV module specially when they are integrated in building and compare it with the real production in same meteorological conditions. The final objective of ths work consists in developing a prediction model easily usable in on-line applications (e.g. monitoring or diagnostic). 90 5 80 REFERENCES 70 60 50 40 30 20 10 0 0 80 160 240 Time (min.) 320 400 480 Figure 5: Evolution of the environmental parameters (percentage values): irradiance (Gmax=909 W/m2, blue line), temperature (Tmax=15.17 °C, red line, dash-dot), wind speed (vmax=5.2 m/s, green line, dash) 45 40 Temperature (°C) 35 30 25 20 15 10 5 0 0.5 1 1.5 Time (sec) 2 2.5 3 4 x 10 Figure 6: Evolution of the PV module temperatures: front glass (blue line), central layer (red line), back glass (green line) We note that there is a good accordance between the modeled temperatures from [8] and [10] and the [1] Flat-plate PV-Thermal collectors and systems: A review. Zondag, H.A. 891–959, s.l. : Renewable and Sustainable Energy Reviews, 2008, Vol. 12. [2] Calculation of the polycrystalline PV module temperature using a simple method of energy balance. Mattei M., Notton G., Cristofari C., Muselli M., Poggi P. 2006, Renewable Energy, 31, p. 553-567. [3] D.L. Field experience with a new performance characterization procedure for photovoltaic arrays . King, J.A., Kratochvil, W.E. e Boyson, W.I. Bower. Austria : s.n., 1998 . 2nd World conference and exhibition on photovoltaic solar energy conversion . [4] Photovoltaic collectors efficiency according to their integration in buildings. Guiavarch A., Peuportier B. 2006, Solar Energy, 80, pp. 65-77. [5] Temperature fluctuation analysis of photovoltaic modules at short time interval. Matsukawa H., Kurokawa K. LAKE BUENA VISTA, FL (USA) : IEEE, 2005. Photovoltaic Specialists Conference. pp. 1816-1819. [6] Convection coefficient equations for forced air flow over flat surface. Sartori E. 2006, Solar Energy, 80, pp. 1063-1071. [7] Effect of urban climate on building integrated photovoltaics performance. Wei Tian, Yping Wang, Jianbo Rein, Li Zhu. 2007, Energy Conversion & Management 48, pp. 1-8. [8] Modelling of a double-glass photovoltaic module using finite differences. Notton G., Cristofari C., Mattei M., Poggi P. 2005, Applied Thermal Engineering, 25, pp. 2854-2877. [9] Field Study and Modelling of Semi-transparent PV in power, Thermal and Optical Aspects. Wong, P.W., et al. 2005, JAABE (4), p. 549-556. [10] Electrical and Thermal Model for PV Module Temperature Evaluation. Tina, G. and Scrofani, S. Ajaccio (FR) : IEEE, 2008. MELECON. [11] A thermal model for photovoltaic systems. Jones AD, Underwood CP. 2001, Solar Energy 70(4), pp.349– 59 Nomenclature of subscript a = ambient bg = back glass cover PV = photovoltaic cd = conduction conv = convention fg = front glass cover gro = ground g = glass pv = photovoltaic r = radiative ref = reference conditions sky = sky

© Copyright 2026