gulf intracoastal waterway barge gate

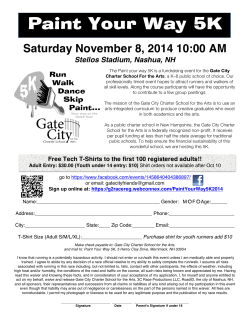

# 33 newsletter DECEMBER 2014 Gerwicknews Gulf Intracoastal Waterway BARGE GATE Barge gate photos: top – structure nearing completion in dry dock, middle – under tow, bottom – trial fit-up installation during flood wall construction period. Top photo courtesy of USACE Team New Orleans. Bottom photos courtesy of CB&I (formerly Shaw E&I). president’s message As part of the 2014 Outstanding Civil Engineering Achievement (OCEA) Award from ASCE for the Inner Harbor Navigation Canal Surge Barrier, the Gulf Intracoastal Waterway Barge Gate reduces the risk of hurricane storm surge flooding in New Orleans. gulf intracoastal waterway barge GATE PHILLIPS 66 RICHMOND TERMINAL MOTEMS AUDIT AND UPGRADES Content MOORING ANALYSES TECHNICAL REVIEW OF THE MID-BARATARIA SEDIMENT DIVERSION EMPLOYEE SPOTLIGHT Gerwick designed a unique, reinforced, lightweight concrete barge gate to close a 150 foot-wide navigation channel in the Gulf Intracoastal Waterway (GIWW). Among other awards, the floating gate won the 2013 National Council of Structural Engineers Award of Excellence for Bridges and Transportation structures. Originally the barge gate was intended to close a temporary navigation channel during construction of the overall project. However, analysis of the tidal fluctuation revealed that large flow velocity would hamper navigation through an adjacent sector gate. Therefore the barge gate was revised to function as a permanent, operational gate to normally remain open to decrease the flow velocity. It is closed for maintenance or a storm. In addition, the barge gate provides a navigation channel during maintenance of the sector gate. CONTINUED ON PAGE 3 # 33 newsletter DECEMBER 2014 2 PRESIDENT’S MESSAGE Winston Stewart, PE [email protected] locations 1300 Clay Street, 7th Floor Oakland, CA 94612 Tel: (510) 839-8972 3780 Kilroy Airport Way #200 Long Beach, CA 90806 Tel: (562) 598-9888 220 West Mercer St., #W-100 Seattle, WA 98119 Tel: (206) 588-2735 400 Poydras St., #1160 New Orleans, LA 70130 Tel: (504) 528-2004 CONTACTS Offshore Marine Structures Dale Berner, PhD, PE, FASCE [email protected] Tunnels, Pipelines, and Immersed Tubes Henrik Dahl, PE [email protected] Wharves, Piers, Ports, and Harbors This issue of GerwickNews may become a souvenir for many, as it will be the last issue published under the Ben C. Gerwick, Inc. banner. On January 1, 2015, Gerwick will formally merge with sister COWI NA, Inc. company, Ocean & Coastal Consultants to form COWI Marine NA. The legal entity will be COWI NA, Inc. and COWI Marine NA will be a business unit thereof. I will head the new company and my counterpart at OCC, John Chapman, will be the market director. Our clients can expect the same quality of service to which they are accustomed. In addition, our clients will have direct access to a wider menu of professional engineering services through one company, COWI Marine NA. In essence, they will have a one-stop shop. Inside this issue, our readers are provided an insight into some of the most challenging and interesting projects that Gerwick is privileged to be engaged in. The Gulf Intracoastal Waterway Floating Gate is a signature feature of the IHNC Storm Surge Barrier in New Orleans. It is the winner of one of the highest honors in the structural engineering world, the 2013 National Council of Structural Engineering Associations (NCSEA) Excellence in Structural Engineering Award (New Bridges & Transportation Structures). The Phillips 66 Richmond Terminal MOTEMS Audit and Upgrades article is a real gem, engagingly and limpidly describing the audit and the solutions that we engineered. The Mid-Barataria Sediment Diversion (MBSD) for the Coastal Protection & Restoration Authority (CPRA) in Louisiana is the first major diversion initiated by the CPRA. Here, we developed Value Engineering (VE) concepts to reduce costs and improve quality using “in-thewet” and “offsite pre-fabrication” construction techniques. The mooring analysis article introduces the procedures and benefits of doing such analyses. Gerwick has performed mooring analyses throughout the U.S. and internationally. Our staff keeps abreast of the latest methods and tools for mooring analyses, thereby ensuring that our clients profit from the most relevant industry practices. I encourage readers to peruse the lists of Gerwick’s recent awards and presentations as well as Paul Guenther’s biography. In closing, may this holiday season be especially gratifying for all of our employees, clients and friends of the company. Ted Trenkwalder, PE, SE [email protected] Water Resources, Waterways, and Concrete Technology Sam Yao, PhD, PE [email protected] Geotechnical and Foundations Winston Stewart, PE [email protected] www.gerwick.com www.cowi.com www.b-t.com www.ocean-coastal.com www.jennyeng.com about ben c. gerwick, inc. Gerwick is an internationally renowned engineering consulting firm that has specialized in the design of marine structures for over 80 years. Our highly qualified staff of civil, structural, geotechnical and coastal engineers has worldwide design and construction engineering experience with piers and wharves, bridges, inland navigation waterways, offshore terminals and platforms, dry docks, harbor facilities, and deep foundations. We have a proven record of accomplishment for producing reliable, economical, innovative, and constructible designs for some of the most challenging design-build and design-bid-build projects. We are experienced in delivering both small and large projects locally, nationally and globally. We were proud to be included in the Engineering News-Record Design Firms Sourcebook 2013, where we were ranked as one of the top ten firms under Marine and Port Facilities. Since 1987, Gerwick has been affiliated with COWI A/S of Denmark. COWI provides services within the field of marine, geotechnical and coastal engineering from six worldwide centers of excellence. Gerwick is a member of the COWI North America group of companies, which also includes Vancouver-based firm Buckland & Taylor Ltd., and two east coast-based firms Ocean and Coastal Consultants, Inc. and Jenny Engineering Corporation. Together we collaborate on marine structures, bridges, tunnels and coastal engineering projects around the world. 3 Final Preparations for Launch in the Drydock in Sulphur, LA, 1/2011 barge gate (continued from cover) Barge Gate Description The barge gate is 190 ft long, 62.5 ft wide, 43.5 ft tall, weighs 5,200 dry tons, and floats at a 14 ft draft. When closed to resist storm surge, it is ballasted to rest on an underwater foundation and abutment. The design requirements include ability to withstand hydrostatic and hydrodynamic loading up to EL +26 ft, allow some wave overtopping, provide for uneven foundation contact, provide a roadway for a truck to access the flood wall, float with a maximum draft of 14.5 ft, and to withstand a tow in the Gulf of Mexico. Intended design life is 100 years in a marine environment using a marine lightweight concrete mix, normal steel reinforcing bars, and construction joints that can be resealed with embedded injection hoses in the event of future leaks. Significant design features include vessel impact resistant walls, a 1 ton/ft2 pressure hull, 1 ksf deck loads, 1,200 kip surge brackets, and 400 kip (ultimate) towing bollards. Other features include an electro-mechanically operated chain-windlass system for opening and closing and a fiber-reinforced epoxy (FRE) ballast system. The ballast system includes marine grade stainless steel embeds and FRE anchor flanges cast into the structure to achieve 100-year design life. Structural Layout The barge gate has four deck levels: a keel deck (bottom at EL -17.5 ft), a middle deck (at EL +5 ft), a mechanical deck (at EL +15 ft) and a top deck at EL +26 ft. Transverse frames and walls are provided on 17’-6” maximum spacing and a watertight longitudinal centerline wall is provided between the keel and middle decks. The longitudinal centerline wall combined with two internal transverse shear walls located at 1/3 of the distance from each end form six internal tank compartments for ballast water. Above the middle deck the transverse cross section is asymmetrical saving structural weight to reduce vessel draft. The cross section geometry eliminates heel and trim. When open, resistance to vessel impact on the barge gate wall parallel to the bypass channel is provided by a 19 inch thick vessel impact wall with embedded steel sections. When closed, the top deck provides a roadway for an AASHTO HS-10 truck to access the flood wall for maintenance. aggregate (Stalite) with low water absorption. After processing in a rotary kiln, it has a 24 hour water absorption of 6% whereas other lightweight aggregates have water absorptions ranging from 15% to 30%. Water absorption for Stalite increases to 9% during mixing or pumping concrete. Stalite meets the requirements of ASTM C330 which covers lightweight aggregates intended for use in structural concrete in which the prime considerations are reducing the density while maintaining the compressive strength of the concrete. For the 3,250 cubic yards of concrete placed, the average unit weight was 110.3 pcf (wet) as determined in accordance with ASTM C 138. The average 28 day compressive strength was 6,700 psi. To ensure this high-strength, lightweight mix could be placed properly and satisfy testing requirements, the specifications required the contractor to conduct trial wall pours prior to constructing the barge gate. The final successful trial wall pour using the Stalite mix design was placed using a tower crane with a 4 cubic yard bucket and tremie pipe within the wall formwork. Concrete Mix Design To achieve a draft limit of 14.5 ft, a maximum concrete unit weight of 115 pcf (wet) was specified. The concrete mix design required a maximum water to cement ratio of 0.4, a slump range of 6 inch to 8 inch. The concrete mix design used a lightweight slate # 33 newsletter DECEMBER 2014 Structural Layout # 33 newsletter DECEMBER 2014 4 Operations Illustration of Barge Gate at Open Position Foundation 100-Year Design Life & Corrosion Resistance To address corrosion, the project specifications provided contractors options to obtain 100-year design life, such as stainless steel reinforcement or cathodic protection. The contractor selected for the project, Baker Concrete, opted to use normal steel reinforcing bars with a concrete mix design containing a calcium nitrite corrosion inhibitor admixture. The use of a corrosion-inhibiting admixture such as calcium nitrite increases the corrosion threshold of carbon steel using 6-15 lb/yd3 (0.15%-0.40%) per unit volume of concrete depending on dose. This admixture chemically reacts with normal reinforcing steel, forming an improved oxide layer on the steel that increases the tolerance of the steel to chloride. Corrosion initiation is delayed and corrosion rates are reduced. The possibility of chloride ion migration is greatest at construction joints due to the potential for irregularities such as honeycombing, air voids, and microcracks. Therefore construction joints are protected from chloride ion migration and water intrusion with PVC waterstops and an innovative reinjectable-resin Fuko hose system manufactured by Greenstreak. The Fuko system injects resin into any irregularities or voids in the construction joint; thus providing additional protection to chlorideion penetration for bars crossing the joint. Approximately 8,000 ft of Fuko hose was installed, making the barge gate the largest application of Fuko product in Greenstreak’s history. The Fuko system allows future reinjection of resin into the construction joints should the need arise. Outfitting of the barge gate to meet the design life requirement used stainless steel for railings, access platforms, watertight doors, and embedded structural plates. The barge gate mechanical systems meets the 100 year design life requirement through the use of: fiberglass reinforced epoxy pipes (FRE) for ballast system, fiberglass pipe spools (embedded in walls/slabs), fiberglass sea chest intakes, stainless steel valves, stainless steel pipe supports and embedded unistruts. Ballast System The ballast system includes three deep well pumps which provide a net pumping capacity of 7,500 gallons per minute. Included is a bilge system and washdown system to remove unwanted sediment and marine debris. These systems have a total of 430 supports, approximately 1/6 of the supports required custom designs. Controls and equipment are provided on board and located within a control room (240 ft2) and mechanical equipment room (740 ft2) underneath the top deck. An opening/closing chain pull system is mounted on the barge gate using two on-board electro-hydraulic powered chainwindlass units with top deck fairleaders and two underwater swivel fairleaders. The chain is 1 3/4 inch diameter stud link oil rig quality with a minimum breaking strength of 380 kips. The chain ends are anchored to a pulling point in the abutment and to a pulling structure adjacent to the open position foundation. The barge gate will normally be ballasted and rest on its open-position foundation at EL -17.5 ft. The open position foundation consists of thirteen reinforced concrete grade beams, pile supported and located to correspond to the barge gate transverse structural support frame lines. This grade beam foundation was constructed in the wet to save the expense of constructing a temporary cofferdam with tremie slab seal. When the barge gate needs to be moved from its open-position foundation to the closed position, ballast water is pumped out of its six internal tank compartments and the gate floats. Once afloat, it pivots 90 degrees about a pin-pile structure and is pulled open or closed by the chain-windlass system. It takes 15 minutes to pull the barge gate from its open position to the closed position. As the barge gate nears the foundation abutment walls, the four stainless steel fabricated pintel brackets embedded into the ends of the barge gate align over four abutment pintels (pins). Contact with the pins is made as the barge gate is ballasted down to its closed position foundation. The pins are sloped to pull the barge gate into contact with a vertical seal on the abutment walls. As the barge gate nears the foundation base it makes contact with a foundation perimeter seal. After this seal is compressed 1 inch the barge gate vertical loads are transferred Mechanical Room 5 to foundation base risers which correspond to the structural framing. The base seal and vertical seal reduce the hydrostatic and hydrodynamic uplift on the barge gate, thereby decreasing the ballast water needed for a storm event closure and reducing the time to close the gate (6 hours). The foundation base risers transfer the dead load of the ballast water and barge gate into a pile supported mat foundation. Lateral load on the barge gate from a storm is resisted by the foundation sill in contact with the barge keel slab and by the two vertical abutment reaction walls parallel to the channel. This was verified with finite element modeling. The abutments and mat are supported by 312 battered piles with a length of 115 ft and 114 vertical piles with a length of 109 ft. Piles are prestressed concrete (2 ft square). Weight Control One of the biggest challenges in the design and construction of the floating barge gate was monitoring its weight and center of gravity. Three feet of minimum clearance from the underwater foundation to the bottom of the barge gate was required, resulting in a maximum draft limit of 14.5 ft. This requirement was complicated by the functional requirements (added weight) due to vessel impact walls, strength to withstand uneven foundation contact, and on-board equipment. Gerwick developed a 3D CAD model including internal reinforcement, and railings/stairs/platforms to aid the calculation of the center of gravity and draft. The calculated draft left little margin for construction inaccuracies; therefore the project specifications included tight construction tolerances, a weight control program and trial pour mock-up walls. Each concrete pour was documented by the contractor for its volume and unit weight while the center of gravity calculation was updated and tracked to predict where ballast would be needed to trim and heel the barge gate to a level floating plane. During construction, concrete formwork was surveyed for compliance with tolerance specifications to ensure walls were plumb and bulging did not occur. Launch and Tow The barge was built on a floating drydock in Sulphur, Louisiana. When launched from the floating drydock the barge gate floated with slightly less draft than predicted demonstrating success in weight control procedures. It was then towed approximately 500 miles through the Gulf of Mexico and up the Mississippi River to the GIWW. The barge gate arrived at the GIWW in time for the 2011 hurricane season so that the barge gate could be installed on its foundation using tug boats. After arrival at the site, installation of mechanical and electrical equipment along and final outfitting were conducted. The barge gate was installed at its pivot pile and commissioned for operations in early 2012. # 33 newsletter DECEMBER 2014 Haskoning of the Netherlands. The barge gate was also closed in October 3, 2013 for Tropical Storm Karen. Summary The marine lightweight concrete mix design with corrosion inhibitor, normal reinforcing steel, PVC waterstop system with Fuko hoses, stainless steel embeds, FRE embeds, and FRE ballast system, produced an economical structure meeting a 100 year design life. Gerwick reduced the amount of ballast and the time to close the gate before a storm hit, by using an innovative base seal underneath its perimeter. The seal also allowed a structural configuration with a reduced weight to minimize the draft. The barge gate is able to withstand storm event waters up to EL +26 ft, a tow through the Gulf of Mexico, navigation vessel impacts, and bridge over any potentially uneven foundation contact points. These features will help ensure New Orleans is ready for the next storm. 2012 Hurricane Isaac On August 28, 2012 Hurricane Isaac made landfall on the Louisiana coast as a Category I hurricane with 80 mph winds. This resulted in a 15 ft storm surge at the barge gate. This gate prevented an estimated $5 billion of flood damage as estimated by Royal project credits Engineer of Record for Barge Gate Civil, Structural, and Mechanical: Ben C. Gerwick Inc., Oakland, CA Mechanical Systems Designer: Herbert Engineering, Alameda, CA Engineer of Record for Barge Gate Electrical: Siver Engineering, Concord, CA IHNC Project Joint Venture Design Partner: INCA Engineers, Bellevue, WA Barge Gate Foundation Designer: CB&I (Formerly Shaw E&I), Baton Rouge, LA Barge Gate Contractor: Baker Concrete Construction, Houston, TX Barge Gate Mechanical Contractor: Tepsco, Deer Park, TX Barge Gate Electrical Contractor: RES Contractors, LLC, Plattenville, LA Concrete Supplier: Port Aggregates, Westlake, LA Concrete Consultant to Designer: George C. Hoff Consulting, Clinton, MS Concrete Consultant to Contractor: Concrete Engineering Specialists, Charlotte, NC Concrete Testing: Louisiana Testing and Inspection, Lafayette, LA Owner: United States Army Corps of Engineers New Orleans District DALE BERNER, PHD, PE, FASCE [email protected] MICHAEL O’SULLIVAN, SE [email protected] MICHAEL GEBMAN, PHD, PE [email protected] # 33 newsletter DECEMBER 2014 6 phillips 66 Richmond terminal motems audit and upgrades Phillips 66 retained the services of Ben C. Gerwick, Inc. for performing the MOTEMS (Marine Oil Terminal Engineering and Maintenance Standards) Initial Audit of their Richmond marine terminal located in the Santa Fe Channel of the Richmond Inner Harbor in the San Francisco Bay. The terminal was built in 1956 and consists of two reinforced concrete wharves, one 228 feet long by 50 feet wide wharf for berthing tankers and one 148 feet long by 50 feet wide wharf for berthing barges. The wharf deck is a cast-in-place reinforced concrete structure supported on 16” octagonal precast prestressed concrete piles. A pipeway structure runs parallel to the shore side of the wharves. The pipeway consists of cast-in-place reinforced concrete beams supported on 16” precast prestressed concrete piles. An overhead steel pipeway, built on top of the concrete pipeway, provides support for the pipelines that run from the tanker wharf to the Kinder Morgan facility, which is adjacent to the Phillips 66 terminal (See Fig. 1). The two wharves and pipeway have a total of 190 vertical piles and 64 battered piles. Gerwick had the role of prime consultant, responsible for planning the audit and putting together the audit team, collecting the existing terminal information, coordinating the above and below water inspections, coordinating the sub-consultant work, and assembling the audit report for submittal to Phillips 66 and the California State Lands Commission (CSLC). Halcrow participated in the project as sub-consultant, being responsible for the audit of the fire protection BERNARDO WAISMAN, PE [email protected] system, the piping, and the mechanical and electrical equipment. The audit report was completed and submitted to the CSLC within the period specified by MOTEMS for a medium risk facility. The terminal is classified per MOTEMS as a medium risk facility because the exposed total volume of oil during transfer is less than 1,200 barrels, the number of transfers per year is greater than 90 and the maximum vessel size is greater than 30,000 DWT. Phillips 66 uses the terminal for loading and unloading liquid bulk hydrocarbon products, including bunker fuel, marine diesel oil, and cutter stock. Adjacent to the Phillips 66 terminal, Kinder Morgan operates a storage and distribution facility for liquid bulk products that include one pipeline for handling propylene tetramer, a hydrocarbon that falls within the MOTEMS jurisdiction. Kinder Morgan has an agreement with Phillips 66 for using the tanker wharf for handling these products. During the Initial MOTEMS Audit, the following berthing and structural items were identified as not being in compliance with MOTEMS requirements: 1) Fender System, 2) Seismic Performance, and 3) Condition of Concrete Beams, Pile Caps, Columns, and Piles. Upon evaluating the results of the audit, Phillips 66 initiated a proactive upgrades program designed to correct the identified deficiencies. Gerwick was contracted for performing the engineering design and construction support required for the terminal upgrades. Figure 1 - Phillips 66 Richmond Marine Terminal 7 # 33 newsletter DECEMBER 2014 Fender System Upgrade The original fender system at the tanker and barge wharves consisted of vertical timber piles spaced at 6’-0” on centers with a timber waler at the top and steel coil springs that provided the energy absorption capacity for the berthing of tankers and barges. During the audit, it was found that this fender system did not have the capacity for dissipating the kinetic energy of the vessels at berthing in accordance with the MOTEMS requirements. It is important to indicate that the size of the vessels calling at the terminal has increased since it was built in 1956. As a result, the approach angle and velocity of the vessels currently berthing at the terminal had to be restricted in order to avoid damage to the wharf and vessels. The new fender system consists of rubber cone fenders with a steel frontal panel of closed box construction with a UHMW-PE facing of low coefficient of friction (See Fig.2). Each fender unit is mounted on a steel frame supported by two steel wide-flange piles. Three rubber cone fenders were installed at the tanker wharf and two rubber cone fenders were installed at the barge wharf. This new fender system was designed to receive vessels of up to 76,000 DWT at the tanker wharf and tank barges of up to 10,000 DWT at the barge wharf. The design of the new fenders was performed in strict conformance with the MOTEMS standards, which require that each rubber cone fender be capable of dissipating the total berthing energy of the design vessel. For the 76,000 DWT tanker, the design berthing angle and velocity, normal to berth, were 6 degrees and 0.26 feet per second, respectively. For the 10,000 DWT barge, the design berthing angle and velocity, normal to berth, were 15 degrees and 0.33 feet per second, respectively. The rated energy absorption capacities are 318 kip-ft for the tanker wharf fenders and 122 kip-ft for the barge wharf fenders. An additional third rubber cone fender was recently installed at the barge wharf, for accommodating tug boats that use the new fueling services provided by Phillips 66. Figure 2 – New Rubber Cone Fender structures, including the tanker and barge wharves, concrete pipeway and overhead steel pipeway. The overhead steel pipeway, which supports the pipelines that run from the tanker wharf to the Kinder Morgan facility, has an offshore segment built on top of the concrete pipeway that runs parallel to the shore side of the wharves and an onshore segment that starts at the north end of the barge wharf and ends at the Kinder Morgan tank farm. The seismic loads and displacements (demand) were calculated performing a linear modal site-specific response spectrum analysis. The analysis indicated that the structures did not meet the MOTEMS seismic performance criteria. The lateral seismic displacements of both wharves where high, creating strains of the pile materials above the limiting values specified in MOTEMS. The calculated maximum seismic displacement demand at top of existing piles was 9 inches for a Level 1 earthquake and 24 inches for a Level 2 earthquake. The analysis was done using the computer program SAP 2000. Push-over analyses of the piles were performed to obtain the maximum allowable displacements without exceeding the strain limits. The soil spring values representing the soil resistance on the piles were based on the p-y and t-z curves provided by Treadwell & Rollo. Upper bound and lower bound spring values and upslope, downslope and horizontal direction cases were analyzed to obtain the worst case for top of pile displacement. All the piles failed for a Level 2 earthquake and a number of piles (the shorter piles close to shore) failed for a Level 1 earthquake. Gerwick evaluated two seismic strengthening schemes. The first scheme consisted of installing 2 foot diameter steel pipe battered piles with cast-in-place concrete caps to resist the seismic loads. The second scheme consisted of installing large diameter vertical steel pipe piles Seismic Upgrade As part of the MOTEMS Initial Audit, Gerwick performed a seismic analysis of the terminal Figure 3 – Upgraded Tanker Wharf Framing Plan # 33 newsletter DECEMBER 2014 8 Figure 4 – Driving 66” Diameter Pile at Tanker Wharf working as cantilever beams. The vertical pile scheme was selected for the seismic upgrade because of its simpler construction and lower cost. The design consisted of installing 66 inch diameter by 1-1/2 inch thick steel pipe piles, eight piles at the tanker wharf and three piles at the barge wharf. The installed length of the piles varied from 102 feet to 106 feet. The cast-in-place concrete pile caps were designed to transfer only horizontal loads from the wharf to the pile, avoiding the transfer of vertical loads and the application of bending moments at the top of the pile. This connection was achieved with cylindrical steel sleeves cast in the concrete before driving the piles. With this strengthening system, it was possible to reduce the seismic displacements to a maximum of 3 inches for a Level 1 earthquake and 12 inches for a Level 2 earthquake. (See Figures 3 and 4). At the start of the design process, Gerwick recommended conducting a pull-out test program of the existing pile prestressing strands, with the Figure 5 – Pipeway Pile Cap with Complete Bottom Repair purpose of determining if the 24 inch embedment of the strands into the pile caps had enough bond capacity to develop the yield strength of the strands and allowing the creation of a moment-resisting plastic hinge. The results of the tests indicated that the 24-inch embedment could develop the yield strength of the strands. Based on these results, the pile to cap connections were modeled as moment-resisting connections, which resulted in a simpler and more cost efficient design. at both wharves, and seven prestressed concrete piles. Gerwick performed a second and more detailed inspection of the damaged elements to obtain the information necessary for preparing drawings with the repair procedures and details. In addition, Gerwick provided construction support for the repairs. The materials for the repairs of beams, pile caps, columns, and vaults were manufactured by Sika Corporation. The materials for pile repairs were manufactured by Fox Industries and Sika Corporation. All the damaged elements were successfully repaired and it is estimated that the repairs will extend the useful life of the structures for at least fifteen years (See Figures 5 and 6). Concrete Repairs During the field inspections performed for the MOTEMS audit, it was found that a number of concrete elements had damage caused mainly by the corrosion of the reinforcing steel. The typical damage consisted of open spalls, closed spalls, cracks and corrosion of the reinforcing steel. The observed damage was in the pipeway pile caps and beams, columns that run between the pipeway level and the deck level, utility vaults Figure 6 – Pile Horizontal Crack Repaired with Epoxy Injection 9 # 33 newsletter DECEMBER 2014 Mooring analyses Ben C. Gerwick, Inc. (COWI Marine) routinely performs comprehensive mooring analysis to inform the structural performance requirements of a berthing facility, or to establish the limits for safe operations at an existing or new marine terminal. A mooring analysis describes the response of moored vessels subjected to wind, waves, currents, and passing vessel effects. These loads may lead to excessive vessel motion, and line breakage, with serious consequences. In fact, pursuant to the Lempert-Keene-Seastrand oil spill prevention and response act of 1990, California State Law requires that a mooring analysis be an integral part of any upgrade or design of a Marine Oil Terminal (MOT). Figure 1 - An Aframax tanker is moored at a berthing facility in Kenai, Alaska. The harsh environmental conditions required a dynamic mooring assessment capable of evaluating the effects of gale-force winds and ice loads on the tanker. Deliverables The typical outcome of a mooring analysis generally falls within two categories. New or upgraded facilities. If the terminal is being repaired or upgraded, a mooring analysis provides tension loads on bitts, bollards, quick-release hooks, compression loads on fenders. Upon completion of the analysis, vessel restrictions may be enforced or a client may elect to proceed with structural upgrades. In challenging environments, performance standards may require upgrading fenders, placing additional mooring points (e.g. “storm bollards”) or increased mooring line capacity. Existing facilities. For an existing port or terminal with no planned upgrade, a mooring analysis is usually warranted before a new vessel can safely berth. In those cases, the analysis will generate the maximum loads and vessel excursion expected during operational and extreme conditions. A typical product is a terminal operating limits (TOLs) document, describing the optimal mooring arrangements for each vessel or class of vessels, environmental limits, and product line disconnection requirements. Modeling Capabilities The assessment of vessel motion in six degrees of freedom under a combination of meteocean conditions can be complex and computationally intensive. To generate reliable results efficiently, Gerwick employs modern software packages like OPTIMOOR that are capable of handling the large collection of input parameters required to conduct a mooring analysis. Meteocean Conditions. A thorough environmental data review usually accompanies a mooring analysis to provide the conditions under which the facility should safely operate. To do so, Gerwick often uses meteocean data collected and processed by international and federal agencies (USACE, NOAA, NWS, WMO) and commercial data. Gerwick then performs meteocean condition assessments using wave transformation and # 33 newsletter DECEMBER 2014 10 hydrodynamic packages such as Mike 21 FM, HD, STWAVE, CMS-WAVE, Delft3D. Vessel parameters cover the vessel type (RO-RO, cargo vessel, oil tanker, barge, etc.) and particulars (e.g. length, beam, and draft). Each vessel possesses individual aero- and hydrodynamic characteristics that are assessed using hydrodynamic packages (AQWA and WAMIT). Mooring hardware and fender types all affect the behavior of the moored vessel. Fenders thrust reaction must be low enough to be withstood by the structure and limit hull pressure. Choosing the right material is critical. While a softer rubber fender will generate smaller loads on both structure and vessel hull, its lower energy absorption capacity can limit the maximum permissible vessel size at the facility. To supplement performance assessments, COWI Marine provides berthing analyses. Mooring line specifics, such as type, mechanical properties and strength are incorporated within the mooring analysis. Line type should match the intended end result: for example, steel wires are appropriate to limit excursion but generate high tension loads, while flexible, synthetic lines can reduce tension loads at the cost of greater vessel movement. Maximum permissible line loads and vessel excursions are specific to each project but should follow locally applicable standards. Dynamic vs. Static Assessments A static approach to mooring analysis is appropriate when only maximum loads and excursions are needed. More demanding projects usually call for a dynamic approach. In locations with nearby heavy ship traffic, passing vessel effects may be significant. In extreme instances, the amount of displaced water by a passing vessel may become sufficiently large to mobilize a moored vessel and induce several feet of sway and surge. COWI Marine incorporates these effects by forcing a mooring system with a timehistory of these loads derived from NAVFAC guidelines. A vessel traffic analysis may be required to assist in deriving these loads. At exposed locations subject to the combined effects of incoming swell and wind-sea waves, anchored barges may experience excessive motions, which can limit utilization during construction or diving operations. Vessels moored improperly may undergo unusual hydrodynamic responses, such as fender bouncing, wave-induced resonance, and line slack. These phenomena may cause premature mooring hardware fatigue and early failure or create unsafe operating conditions that a regular static analysis may not capture. In locations with large tidal amplitudes, or during a tsunami drawdown, steep line angles between the vessel and the berthing facility may develop rapidly. A dynamic analysis is also useful to assess flexible mooring systems such as nested vessels (ship-to-ship mooring), Single & Multiple Point Mooring (SPM/MPM) and Catenary Buoy Mooring (CBM) systems. Unlike a traditional mooring arrangement, these systems achieve an “in-the-mean” steady state that requires time-domain capabilities. Signature Projects COWI Marine provides mooring analysis services for private and public clients in the Americas, in the Middle East and South East Asia, through COWI A/S. A few projects are highlighted below. ›Single-point mooring to multiple-point mooring upgrade, Chiriqui Grande, Panama. COWI Marine evaluated the performance of a flexible MPM system for the mooring of VLCC tankers in Panama at a location exposed to storm winds, wind-sea and swell waves. Owner: Petroterminal de Panama, 2011. ›Pier 12, Port of San Diego, CA. COWI Marine (COWI Marine) assessed mooring demand and associated loads on structure for a range of US Navy vessels in the Owner: Port of San Diego, CA. US Navy, 2012. ›Mooring system evaluation, Semarang, Java, Indonesia. COWI Marine performed a feasibility study assessing the relative performance of a yoke tower and an island berth as tentative mooring solutions for a floating storage and re-gasification unit (FSRU) requiring ship-to-ship mooring. Owner: PT Pertamina, 2014. JEAN O. TOILLIEZ, PHD, PE [email protected] Figure 2 - Sample mooring arrangement as modeled in OPTIMOOR featuring fenders (in green), lines (black) and wire tails (orange) and mooring points (lettered blue dots). SOREN MORCH, PE [email protected] 11 # 33 newsletter DECEMBER 2014 Mid-Barataria Sediment Diversion Site Location technical review of the midbarataria sediment diversion The Coastal Protection & Restoration Authority (CPRA) commissioned Atkins North America, Inc. (Atkins) and Ben C. Gerwick, Inc. (Gerwick) to perform an Independent Technical Review (ITR) of the major design deliverables for the 30% design of the BA‐153 Mid– Barataria Sediment Diversion (MBSD) project. Together, the Atkins/ Gerwick team worked with the CPRA staff to evaluate the 30% design deliverables as presented by the primary project designer, HDR, Inc. (HDR), during the summer of 2014. The MBSD is the first major diversion design initiated by the CPRA. When commissioned, the MBSD would restore the natural deltaic system of the Barataria Basin. Louisiana’s Comprehensive Master Plan for a Sustainable Coast (CPRA 2012) concluded that sediment diversions are one of the critical elements to addressing the land loss crisis along Louisiana’s coast. Sediment diversions such as the proposed MBSD provide a conveyance mechanism for delivering riverine sediment to areas of degraded coastal wetlands. The 30% design submittal correctly points out that for the case of the “FutureWithout- Project”, FWOP, the Mid‐ Barataria Basin will be seriously degraded within a few decades. The MBSD is just north of the community of Ironton, with the intake located at river mile (RM) 60.7 above the Head of Passes (AHP), see figure. The MBSD would traverse the Mississippi River and Tributary (MR&T) Levee, Belle Chase Highway (LA 23), New Orleans and Gulf Coast Railway (NOGC), the Non-Federal Levee (NFL), low-lying agricultural land, and would terminate in the Barataria Basin. Major design components of the base design of the MBSD diversion consist of an inlet channel, diversion structure, conveyance complex (conveyance channel, guide levees, and associated structural elements), back structure, and outfall channel. The 30% MBSD design process employed state-of-the-art, sitespecific data collection methods in the Mississippi River and a sophisticated suite of numerical models of a portion of the Mississippi River, the diversion and the receiving area. The 30% base design was laid-out to accommodate 75,000 cubic feet per second (cfs) design flow and to use traditional in-the-dry construction methods. Additional preliminary alternate designs were developed with a variety of targeted design flow rates and associated inlet configurations. In reviewing the alternates generated by HDR, we were able to develop variations on the VE concepts that the CPRA and HDR could consider in order to further reduce construction costs using more advanced “in-the-wet” and “offsite prefabricated” construction methodologies, while likely maintaining the cited objectives of the MBSD. Furthermore, our technical review indicated the potential for greater construction cost savings; the CPRA and HDR are now considering invert elevation and flow rate variations to the design. The Atkins/Gerwick team recommended that the design should proceed using the original design discharge objective of 75,000 cfs, and that the base design be suitable for expansion, if needed, in the future. The Atkins/Gerwick team also recommended that additional design information be developed before the 60% design is initiated, including more rigorous modeling of the water surface elevation in conjunction with the geomorphology studies. DENNIS LAMBERT, PE [email protected] DALE BERNER, PHD, PE, FASCE [email protected] PRESENTATIONS PAUL GUENTHER, PE, SE [email protected] (206) 588-2735 EMPLOYEE SPOTLIGHT As the Pacific Northwest Practice Leader, Paul Guenther, P.E., S.E. focuses on delivering Gerick services in Alaska, British Columbia, Washington, and Oregon. Paul was born, raised, and attended college in Wyoming, where he received his B.S. in Civil Engineering and M.S. in Civil Engineering (Structures) from the University of Wyoming. Paul has spent most of his 26-year consulting career working in the Seattle, Washington area, where he has served as a structural design engineer, task manager, project manager, and, for the last three and a half years, as Area Manager in Gerwick’s Seattle office. Paul specializes in the planning, design, and construction of bridges and marine/ port facilities. Paul has led the designs of over 20 bridge projects during his career. He recently led Design-Build efforts for a precast, post-tensioned segmental I-girder bridge with spans up to 215 feet, that utilized 100-inch deep precast girders, the largest ever used in Washington State. Paul’s other notable bridge projects include the half-mile long Vermillion Bridge between South Dakota and Nebraska, and the Wine Country Road Bridge in Prosser, WA, modeled after a vintage 1930’s slab arch bridge. On the marine/port side, Paul has been involved in numerous container terminal design and construction projects--both new facilities and upgrade projects--including project work in Oakland, Los Angeles, Seattle, Tacoma, Jacksonville, and Boston. Paul has led container wharf upgrade design work at the Port of Seattle’s Terminals 18 and 46, enabling these facilities to be strengthened to support post-Panamax container cranes. Most recently, Paul led structural design efforts for the new Elliott Bay Seawall project for the City of Seattle, engineering a unique precast concrete solution. ›› Dale Berner, PhD, PE, FASCE; April 30, 2014; ASCE Ports and Waterfront Infrastructure Technical Session; The Inner Harbor Navigation Canal Lake Borgne Storm Surge Barrier -- Protecting the Coastline from Extreme Storm Surge and Sea Level Rise ›› Dale Berner, PhD, PE, FASCE; June 1-5, 2014; PIANC World Congress; P3 Concept for an Integrated New York Bight Storm Surge Barrier & Transportation System ›› Hamid Fatehi; June 1-5, 2014; PIANC World Congress; Transformation of Old Pier 27/29 to New Cruise Terminal ›› Ted Trenkwalder, PE, SE and Jack Gerwick, PE; June 1-5, 2014; PIANC World Congress; Port of Redwood City: New Wharf and Climate Change Considerations ›› Paul Guenther, PE, SE, and Michael Gebman, PhD, PE; September 6-9, 2014; PCI Convention and National Bridge Conference; Innovative Use of Precast Concrete for the Elliott Bay Seawall Replacement Project ›› Jean O. Toilliez, PhD, PE, and Todd J. Mitchell (Fugro Pelagos, Inc.); November 10, 2014; 91st Coastal Engineering Research Board Meeting; Best Practices for Sustainable and Resilient Coastal Development through Consideration of Local Sea Level Dynamics ›› Jack Gerwick, PE and Jean O. Toilliez, PhD, PE; October 7-8, 2014; California State Lands Commission Prevention First Conference; Adaptive Measures for Sea Level Change ›› Jean O. Toilliez, PhD, PE and Jack Gerwick, PE; October 7-8, 2014; California State Lands Commission Prevention First Conference; Vessel Traffic Analysis in the Carquinez Strait ›› Ted Trenkwalder, PE, SE; October 7-8, 2014; California State Lands Commission Prevention First Conference; Crescent City, CA: Tsunami Damage and Lessons Learned. ›› Jean O. Toilliez, PhD, PE and Todd J. Mitchell (Fugro Pelagos, Inc.) and Austin Becker (Univ. of Rhode Island); November 6-8, 2014; ASCE 2014 International Conference on Sustainable Infrastructure (ICSI); Sea-level Change Considerations for Marine Civil Works COPRI Committee Update on Best Practices ›› Sam Yao, PhD, PE and Hamid Fatehi, PE, SE; November 11, 2014; SEAONC November Dinner Meeting; Floating Cofferdam for Repair of the Washington State SR-520 Floating Replacement Bridge AWARDS FIDIC Award ›› 2014 FIDIC Outstanding Project of the Year Award (International Federation of Consulting Engineers) for the Inner Harbor Navigation Canal Lake Borgne Surge Barrier Project ›› 2014 SEAOC Award of Merit in Structural Engineering (Infrastructure): Floating Cofferdam for Repair of the Washington State SR-520 Floating Replacement Bridge ›› 2014 NCSEA Excellence in Structural Engineering Award Outstanding Project (New Bridge and Transportation Structures) for the Floating Cofferdam for Repair of the Washington State SR-520 Floating Replacement Bridge Copyright: For permission to reprint articles or for any marketing related questions, email [email protected] © 2014 Ben C. Gerwick, Inc. All rights reserved.

© Copyright 2026