ICFD11-EG-4103

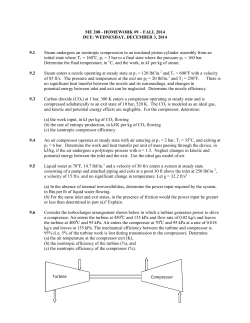

Proceedings of ICFD11: Proceedings of ICFD11: Eleventh International Conference of Eleventh International Conference of Fluid Dynamics Fluid Dynamics December 19-21, 2013, Alexandria, Egypt December 19-21, 2013, Alexandria, Egypt ICFD11-EG-4XXX ICFD11-EG-4103 Design and Optimization of a Multi-Stage Axial-Flow Compressor Prof. Dr. Atef M. Alm-Eldien Mech. Power Eng. Dept. Faculty of Eng. Vice-president for Students Affairs Port-Said University, Egypt [email protected] Prof. Dr. Ahmed F. Abdel Gawad Mech. Power Eng. Dept., Faculty of Eng., Zagazig Univ., Egypt Currently: Mech. Eng. Dept. College of Eng. & Islamic Architecture Umm Al-Qura Univ., Saudi Arabia Fellow IEF, Assoc. Fellow AIAA Member ASME, ACS, SIAM, AAAS Prof. Dr. Gamal Hafaz Mech. Power Eng. Dept. Faculty of Eng. Port-Said University Egypt Eng. Mohamed G. Abd El Kreim M.Sc. in Mech. Power Eng. Steam Turbine Maintenance Engineer Abou Sultan Power Plant East Delta Electricity Production Company Egyptian Electricity Holding Company Egypt [email protected] [email protected] I. INTRODUCTION I.1 Previous Investigations ABSTRACT The objective of this paper is to define a methodology for the design and analysis of multistage axial-flow compressors. A numerical methodology is adopted for optimizing the efficiency at the design point of a fifteenstage axial-flow compressor with inlet guide vanes (IGV). The calculations are carried out along the mean streamline using the principals of thermodynamics and aerodynamics. A computer program was developed that simulates the compressor model. By specifying the geometry specifications (tip clearance, aspect ratio, thickness-chord ratio, blockage factor, etc.) and design parameters (mass flow, rotational speed, number of stages, pressure ratio, etc.), an accurate numerical model can be generated. This modeling technique is much simpler than the usual computational methods that need much more modeling/programming effort and computer run-time. Starting from a newly-designed axial-flow compressor, an optimized version is obtained with improved design-point efficiency. So, once we get the optimized geometry of the compressor, the original geometry is altered to maximize the efficiency at the design-point. Concerning the optimized version, analytical relation between the isentropic efficiency of the compressor and the flow coefficient, the work coefficient, the flow angles and the degree of reaction are obtained. KEYWORDS Axial-flow optimization. compressor, Efficiency, There is a large volume of literature on compressor design and its design parameters. However, the design method is different from one research to another. The intention of this review is to show the reader the related work and to orient the reader where the current work stands in relation to the literature. Barbosa [1] used a streamline curvature for the flow calculation along a multi-stage axial compressor of known geometry. In his work, many streamlines are adopted from hub to tip of the blades and divided in sections applied at the inlet and outlet of each row. Hence, all flow properties can be determined at each point of the intersection among the sections of the cascade and the streamlines forming control surfaces. Teinke [13] used a mean-line stage stacking method for axial-compressor prediction. In his method, the calculations are based on the mean streamline of the axial-compressor channel. The flow properties such as temperature, pressure, velocity and the dimensions of the equipments including the balding angles are determined at half blade. He stated that his method, when simulated in computer, presented fast numeric convergence and sufficient accurate results for a first analysis of the compressors performance. Casey [3] presented a computational program to calculate the efficiency of a single-stage axial compressor to analyze the onedimensional condition with a pressure ratio of 1.2. The author described the importance of analyzing the incidence, deviation, profile losses, secondary losses and boundarylayer limits from hub tip related with the tip clearance in order to predict the axial-compressor performance. The deviation angle was obtained through Carter's rule [2]. He used Lieblein's model [10] to calculate the profile losses. The effect of the relative Reynolds number corrections to the friction losses was calculated by Koch's model [8] and Performance 1 the Mach number correction was done by Jansen, and Moffatt procedure [7]. Seyb [12] presented a program for the design and prediction of an eight-stage, constant outerdiameter, axial compressor. As can be seen from the above literature survey, there is a real need for a better direct method for the design and optimization of the multi-stage axial compressor. The method should consider all the parameters that affect the compressor performance and be reliable for all the compressor stages. Therefore, a new method is introduced in this paper to achieve these objectives. The method is fully explained in the following sections. I.2 Present Study This paper is divided in two main parts. The first part concerns the design of the axial-flow compressor. A computer program is developed for this purpose by the commercial software "Visual Basic". Figure 1 shows a layout of the program window. The input data are typed in the left portion of the window. The program uses "Engineering Equation Solver (EES)" [15] to obtain air properties at different steps of calculation. The program is developed using the thermodynamics and aerodynamics correlations. The results of the program represent an important preliminary design-step that can be further tuned using the Computational Fluid Dynamics (CFD) simulations. When the program finishes calculation, three graphs are obtained. The upper graph illustrates the variation of geometry over the length of the compressor. The lower-left graph shows the velocity diagrams (triangles) in a particular stage. The third graph (lowerright) is to check the surge situation. The user can choose the stage that he wishes to check. The results of the program were validated using the data of reference [6]. The validation covers the data of a fifteen-stage axial-flow compressor. Generally, good agreements were achieved for the geometry and dimensions as well as gas parameters. Fig. 2 Layout of the optimizing program window after finishing calculation. The second part of this paper is devoted to the optimization of design-point efficiency. A second program was developed to maximize the efficiency at design-point according to some constraints. So, the geometry of the compressor that is obtained by the first program is fed to the second program, where an analytical relation between the efficiency and different design parameters is obtained. II. ANALYSIS II.1 Axial-Flow Compressor Design The design process starts with the calculation of the areas at the channel inlet and exit to accommodate the desired mass flow-rate and pressure ratio. Then, the calculation of both the total pressure and total temperature at the inlet and outlet of each stage is carried out. Consequently, velocity triangles, blade angles and losses are calculated to end up with an estimation of the design performance. The calculation process is divided into separate modules. Figure 3 illustrates the overall structure of the calculation process for the whole compressor. Fig. 1 Layout of the program window after finishing calculation. Fig.3 Overall structure of the calculation process for the whole compressor. 2 Cx • Assumptions 1. Two-dimensional flow. 2. Identical balding (α1 = α3) at the mean radius. 3. Constant mean radius. As the fluid is taking its way towards the end of the compressor, boundary layer starts to grow on the compressor housing. This results in narrowing the path of the fluid flow. This phenomenon is accounted for by the introduction of a suitable blockage factor. To achieve a prescribed duty case, the calculation process encompasses the following steps: 1. Selection of the duty coefficients (Ø) and number of stages to achieve the specified compressor design flowrate and pressure ratio. 2. Calculation of the air angles for each stage at the mean radius. 3. Determination of the variation of the air angles from root to tip. 4. Blade pitch chord ratio may then be selected to satisfy aerodynamic loading parameters such as lift coefficient and diffusion factor. Fig.5 Assembled velocity triangles for a stage. • Dimensionless velocity triangles Considering the velocity triangle of a single stage, Fig. 3, we can see that the overall shape of the velocity triangles is governed by the three velocities Cx, ΔCθ and U. We can show that Cx, and ΔCθ are related to the flow coefficient φ and work coefficient ψ as follows: Fig.4 Meridional view of a multi-stage compressor. φ = c x from which we get The meridional view of a multi-stage compressor that is shown in Fig. 4 illustrates the main features of blading and annulus: 1. An inlet guide vane blade row to provide pre-whirl into the first stage. 2. U cx = φ U Δ ψ = h2o U From Euler pump, Δ h o = U( c θ 2 − c θ1 ) = UΔ cθ A set of repeating stages, each comprising a rotor followed by a stator. From which we get Δ c θ = ψU 3 (1) Eq. 3, we get (2) To make the velocity triangles dimensionless, we divide all velocities by the blade speed U. The outcome of this is shown in Fig. 4 from which important results is obtained. α =α 1 ⎛1⎛ 1 ⎞ ⎞ Inflow = arctan ⎜⎜ ⎜ 1 − R − ψ ⎟ ⎟⎟ 2 ⎠⎠ ⎝φ ⎝ 3 ⎛1⎛ 1 ⎞ ⎞ Outflow angle = arctan ⎜⎜ ⎜ 1 − R + ψ ⎟ ⎟⎟ 2 ⎠⎠ ⎝φ ⎝ ⎛1⎛ 1 ⎞ ⎞ Relative inflow angle β 1 = arctan ⎜⎜ ⎜ R + ψ ⎟ ⎟⎟ 2 ⎠⎠ ⎝φ ⎝ α ⎛1⎛ 1 ⎞⎞ ⎜ R − ψ ⎟ ⎟⎟ φ 2 ⎠⎠ ⎝ ⎝ w1 = φ 2 + ⎛ R + ψ ⎞ ⎜ ⎟ U 2 ⎠ ⎝ w2 = U 2 Relative outflow angle 2 Rotor relative outflow velocity ⎛ ψ⎞ φ 2 + ⎜ R− ⎟ − h 1 = − h 2 2 ⎛ ⎞ ⎛ ⎞ = ⎜ h 02 − c 2 ⎟ − ⎜ h 01 − c 1 ⎟ = ⎜ 2 ⎟ ⎜ 2 ⎟ ⎝ ⎠ ⎝ ⎠ h ⎜ ⎝ h 03 − 2 ⎟ ⎠ − ⎜ ⎝ h 01 − 2 ⎟ ⎠ = h 03 01 = Δ h h 2 h 1 02 − h ( ) ( ) c θ 2 − c θ 1 = (c θ 2 − c θ 1 )(c θ 2 + c θ 1 ) 2 2 Introducing Eq. 6 into Eq. 5, we have Δ h0 (c θ 2 + c θ 1 ) h 2 − h1 = Δ h 0 − 2U So, the reaction R becomes 1 (c + c ) R = 1− 2U θ 2 θ 1 From which cθ 2 + cθ 1 = 2U (1 − R ) Thus, we have cθ 1 = 1 − R − 1 ψ U 2 cθ 2 = 1 − R + 1 ψ U 2 0 (5) 01 L Rotor entry and stage exit 2 Stator inflow velocity (21) 1 l 2 m D m But we have tan β = 1 1⎛ 1 ⎞, ⎜R + ψ ⎟ 2 ⎠ 1⎛ 1 ⎞ tanβ = ⎜ R − ψ ⎟ 2 φ 2 ⎠ ⎝ φ⎝ (23) Hence, (6) tan β m = ( β 1 tan 2 1 + tan R β )= φ (24) 2 Substituting these into Eq. 22, we have the alternative form for CL involving the duty coefficients ( φ , ψ): (7) (8) C L ⎛t = 2⎜ ⎝l ⎡ ⎤ 2ψ R ⎞⎢ ⎥ − ( )C D ⎟⎢ φ ⎠ ⎢ 4 2 + 1 ⎥⎥ φ ⎦ ⎣ (25) (9) Considering the drag coefficient, defined by (10) CD = 1 2 (11) wθ 1 = 1 − cθ 1 = R + 1 ψ (26) ⎛t⎞ = ζ ∞ ⎜ ⎟ cos β ∞ 2 ⎝l⎠ ρ w∞ l D Where, the cascade loss coefficient is based on the vector mean velocity w∞ (12) 2 wθ 2 = 1 − cθ 2 = R − 1 ψ (13) U U 2 We note that the dimensionless velocity triangles and hence the blade shapes required to achieve them are totally determined by the stage duty coefficients φ ,ψ and R. It follows that all angles and velocities may be expressed as functions of φ andψ as follows: U 2 The dimensionless parameters that indicate profile aerodynamic quality are the lift and drag coefficients CL and CD. It is important therefore to express CL and CD in terms of the duty coefficients which have a total control over the shape of the velocity triangles. Lift coefficient for a cascade can be expressed in terms of the relative inflow and outflow angles β1 and β2, the vector mean of them β∞ and the pitch to chord ratio, t/l as follows: t (22) C = 2 (tan β − tan β )cos β − C tan β But since there is no work or heat input through the stator, h02 = h03 and thus h02 - h01 = h03 - h01 = Δh0. Also, since the axial velocity is assumed to be constant, we have 2 2 2 2 2 2 c 2 − c1 = c x + c θ 2 − c x + c θ 1 = (19) • Lift and drag coefficients in terms of duty coefficients Then, the numerator is written as − (17) (20) c 2 = φ 2 + ⎛ 1− R + ψ ⎞ ⎜ ⎟ U 2 ⎠ ⎝ Since the stages are repeating for which entry and leaving velocities are identical, C3 = C1, the denominator of Eq. 3 may be simplified to 2 2 ⎛ (4) c 3 ⎞⎟ ⎛⎜ c 1 ⎞⎟ ⎜ 3 (16) 2⎠ ⎝ velocities Swirl velocities Wθ2 and Cθ1 can be related to φ ,ψ and R as follows − (3) R = h 2 h1 − h 3 h1 (15) Rotor relative inflow velocity (18) c 1 = c 3 = φ 2 + ⎛ 1− R − ψ ⎞ ⎜ ⎟ U U 2 ⎠ ⎝ Fig.6 Dimensionless velocity triangles for a stage. (14) 2 β 2 = arctan ⎜⎜ h angle U ζ∞= (Δ p0)loss Since, 4 (27) 1 2 ρW ∞ 2 ζR= Δ poR & 1 ρ W 12 2 ζs= Δ p os 1 ρ C 22 2 (28) Where, ζR,ζs are the rotor and stator loss coefficients expressed in terms of the exit velocities C2 and w3 relative to the blade rows. Hence, we get 2 2 Δ poR ζR= 1 ρ W 12 2 (29) ⎛ cos β 1 ⎞ ⎛ w∞ ⎞ ⎟⎟ = ζ ∞ ⎜⎜ cos β ⎟⎟ w ⎝ 1⎠ ∞⎠ ⎝ = ζ ∞ ⎜⎜ So that CD becomes ( 2 2 3 cos β ∞ ⎛ t ⎞ 2φ 4 φ + (1 + φ ) = ζ 1⎜ ⎟ 3 ⎝ ⎠ cos 2 β 1 ⎝l⎠ 4φ 2 +1 2 ⎛ ⎞ C D = ζ 1⎜ l ⎟ t ( ) ) (30) From the definition of diffusion factor (DF), Lieblein et al. [10], we have DF = 1 − cos cos β1 β2 + β1⎛t ⎞ cos ( ⎜ ⎟ tan ⎝l⎠ 2 β 1 − tan β 2 ) (31) The rotor and stator blade rows will have different profile geometry. In order to select suitable values of pitch/chord ratio t/l to control aerodynamic loading, we have for the rotor 2 2 (32) 4φ + (1−ψ ) t ψ DF R = 1− 4φ + 2 (1−ψ ) 2 ⎛ ⎞ +⎜ ⎟ ⎝l⎠ 4 2+ φ (1−ψ ) 2 And for the stator, we have DF = 1− S ⎞ ⎜ ⎟ (tan α − tan α ) cos α 2 ⎝l ⎠ φ + (1− R −ψ / 2 ) + 1 ⎛ t ⎞ ψ ⎜ ⎟ 2 + φ (1− R −ψ / 2 ) ⎝ l ⎠ φ + (1− R +ψ / 2 ) = 1− cos α 2 + cos α 2 ⎛ t 3 2 Fig.7 Flowchart showing the iterative process for axial velocity. (33) 3 s 2 2 2 2 2 • Calculation of static properties 2 s Before the calculation begins, the inlet geometry must be determined. To be able to find the inlet geometry, the inlet flow velocity Cm must be known. Since this velocity is unknown, an iterative process is made to find Cm. With the help of mass continuity, a new flow velocity is calculated. This value is then used to start over the calculation until convergence is accomplished. The first step is to get the thermodynamic properties at the inlet of the compressor. The ambient pressure and temperature are known and from them Cp and γ are determined. With these properties are known, the iteration process can begin, Fig. 7. Fig.8 Compressor stage (T-S) diagram. 5 • Calculation of the equivalent diffusion ratio (Deq*) • Calculation of static pressure and temperature at rotor inlet (P1, T1) 1. 2. 3. 4. cos(β 2) ⎡ From EES, find h01, S01, K01 and Cp01 using (P01, T01). Find h1 = h01 - C12/2. From EES, find ρ1, Cp1, k1 and μ1 using (h1, S1 = S01). Find T1 = T01 - (C12/2 × Cp1). Deq* = cos( ) ⎢1.12 + 0.61 β1 ⎢ 2 cos (β1) ⎣ ⎛ k ⎞ ⎜ 1 ⎟ σ ⎤ (tan(β 2) − tan(β1))⎥⎥ (35) ⎦ • Calculation of the compressor losses ⎛ ⎞⎜ k −1 ⎟ 5. Find p = p ⎜ T 1 ⎟⎝ 1 ⎠ 1 01 ⎜ ⎟ ⎝ T 01 ⎠ • Calculation of static pressure and temperature at rotor outlet stator inlet (P2, T2) • Profile loss model The profile loss model used is a modified version of the two-dimensional low speed correlation of Lieblein et al. [10], Fig. 9. 1. Find compressor exit temperature ⎛ 1 ⎞⎛ k −1 ⎞ ⎜ ⎟⎜ 01 ⎟ ⎜ η ⎟⎜ k ⎟ p ⎝ ⎠⎝ 01 ⎠ (π ) Te 01 2. Find stage temperature rise ΔT=(Te-T01)/n_stg 3. Find T03 = T01 + ΔT =T ⎛ k1 ⎞ ⎜ ⎟ 4. 5. 6. 7. 8. 9. ⎜ k −1 ⎟ Find p = p ⎡1+ η p Δ T ⎤ ⎝ 1 ⎠ ⎢ ⎥ 03 01 T 01 ⎦⎥ ⎣⎢ P02 = P03, T02 = T03 From EES find h02, S02 using P02, T02 Find h2 = h02- C22/2 From EES find ρ2, Cp2, k2, μ2 using h2, S2 = S02 Find T2 = T02 - (C22 / 2 × Cp2) ⎛ k ⎞ 2 ⎟ ⎜ ⎜ −1 ⎟ 10. Find p = p ⎛⎜ T 2 ⎞⎟ ⎝ k 2 ⎠ 2 02 ⎜ ⎟ ⎝ T 02 ⎠ • Calculation of static pressure and temperature at stator outlet (P3, T3) 1. From EES find h03, S03 using P03, T03 2. Find h3 = h03 - C32/2 3. From EES find ρ3, Cp3, k3, μ3 using h3, S3 = S03 4. Find T3 = T03 - (C32/2 × Cp3) 5. ⎛ Find p = p ⎜ T 3 03 Fig. 9 Profile loss parameter with variation of Mach number [10]. The profile loss parameter is expressed as ζ ⎞ ⎛ k 3 ⎟ ⎜ ⎜ k −1 ⎟ ⎞ 3 ⎟⎝ 3 ⎠ f ( x) = a 0 + a1 x + .... + a n −1 x n −1 + a n x n The starting rotor inlet-conditions will have the same velocity and radius outlet of the previous stage and the stagnation properties is taken from the previous stage. • The polynomial coefficients are listed below rm,1 = rm,3(i-1), Cm,1 = C m,3(i-1), α1 = α3(i-1) P01 = P03 (i-1), T01 = T03 (i-1), h01 = h03 (i-1), S01 = S03 (i-1) • Calculation of the pitch-chord ratio (s/c) The calculation of the pitch-chord ratio is based on the diffusion ratio. The input parameters consist of the relative inlet and outlet flow angles, the different axial velocities and radiuses and also the diffusion factor M1 a0 a1 a2 a3 a4 0.3 -8.26097e-02 2.62982e-01 -2.66675e-01 1.14774e-01 -1.61839e-02 0.7 -1.30107e-01 3.68490e-01 -3.56939e-01 1.48500e-01 -2.08264e-02 1.0 -1.36535e-01 3.78126e-01 -3.66336e-01 1.52219e-01 -2.13465e-02 • End-wall loss A correlation is used to determine the end-wall losses based on a numerous sets of compressor data where the parameters, tip clearance, aspect ratio, and mean-line loading where systematically varied. These parameters can be correlated as in Fig. 10, [4]. (β 1 , β 2 , c m1 , c m2 , r m1 , r m2 , DF ) ⎞ w 2 ⎞⎟ ⎛⎜ r1 + r 2 ⎟ ⎟ w1 ⎜ w1 ⎠ ⎝ r 2 wθ 2 − r 1 wθ 1 ⎟⎠ (36) v2 A fourth-order polynomial fitting method has been used to interpret the graph that has the form ⎜T ⎟ ⎝ 03 ⎠ The above calculation process is repeated for each stage noting that: S ⎛⎜ = DF − 1 + C ⎜⎝ 2 0.5 v12 cs(α 2) = f ( M 1 , D eq ) p (34) 6 dynamic head, the minimum dynamic head and the dynamic head at zero axial velocity as given by the following equation, Fig. 11. F ef = 2 C + 2 .5 C 2 min + 0 .5 U 2 4C 2 (40) 2 C min = 2 sin (α + β ), if (α + β ) ≤ 90 and β ≥ 0 2 C 2 C min = 1, if (α + β ) > 90 2 C 2 2 C min = U 2 if β < 0 2 2 C C Fig. 10 End-wall loss parameter with variation of tip clearance. The end-wall loss parameter is expressed as h 2 ζ e v12 = c v2 ⎛ε ⎞ f ⎜ , DF ⎟ ⎝C ⎠ (37) A fourth-order polynomial fitting method has been used to interpret the graph it has the form f ( x) = a 0 + a1 x + .... + a n −1 x n −1 + a n x n • The polynomial coefficients are listed below Tip Clearance a0 a1 0.0 3.23881e00 -3.66895e01 1.60855e02 -3.14825e02 2.32625e02 0.02 2.86933e00 -3.18679e01 1.36001e02 -2.58533e02 1.85224e02 0.04 -2.00381e-01 1.04984e00 3.12191e00 0.07 8.18792e-01 -8.62635e00 3.57996e01 -6.61454e01 4.61697e01 0.1 2.38135e-01 -2.36201e00 1.01622e01 -1.92343e01 11.36794e01 • a2 a3 -2.0345e01 a4 Figure.11 Diagram giving definition of Fef. Figure 12 shows a correlation of stalling pressure-rise coefficient (CpD) and of diffusion-length to exit passagewidth (L / g2). 2.48570e01 L g2 = σ ( ) ⎛θ ⎞ cos β b 2 cos⎜ ⎟ ⎝2⎠ Calculation of the stall/surge A relationship created by Koch [8] is used to determine how close a stage to stall/surge. By calculating the static pressure rise coefficient, Cp, based on pitch-line dynamic head, and comparing it to the maximum static pressure rise, Cp,max, a good indication of how close a stage is toward stall is given. The static pressure-rise coefficient and the maximum pressure-rise coefficient are as follows: cp ⎡ ⎢⎛ c p T 1 ⎢⎜⎜ ⎢⎝ ⎢⎣ = k −1 k ⎤ ⎥ − 1⎥ − ⎥ ⎥⎦ 2 2 W1 −C2 2 p3 ⎞ ⎟ p 1 ⎟⎠ ( (U 22 − U 12 ) 2 ) ⎛ Cp ⎞ ⎛ Cp ⎞ ⎛ Cp ⎞ ⎟ Cp,max= CpDFef ⎜⎜ ⎟⎟ ⎜⎜ ⎟⎟ ⎜⎜ ⎟ ⎝ CpD⎠Re⎝ CpD⎠ε ⎝ CpD⎠Δz (38) (39) Fig.12 Correlation of stalling pressure-rise coefficient (CpD). Where, Fef is the effective dynamic-pressure coefficient that is represented by a weighted-average of the free-stream 7 (41) A fifth-order polynomial fitting method has been used to interpret the graph that has the form f ( x) = a 0 + a1 x + .... + a n −1 x n −1 + a n x n • The polynomial coefficients are listed below a0 a1 a2 a3 a4 a5 7.6431e-02 4.916e-01 -2.5166e-01 9.1688e-02 -1.9627e-02 1.7779e-03 Figure 13 shows the effect of tip clearance on stalling pressure-rise coefficient (CpD). g= ( ( ) ( )) π r m cos β b1 + cos β b2 • Fig. 14 Effect of axial-spacing on stalling pressure-rise coefficient (CpD). (42) Z Where, Z denotes the number of blades in one row. Figure 15 shows the effect of Reynolds number on stalling pressure-rise coefficient (CpD). The polynomial coefficients are listed below a0 a1 a2 a3 a4 a5 1.1191e00 -6.1567e-01 9.6073e-01 -2.2107e-01 -7.4519e-01 5.1421e-01 Fig. 15 Effect of Reynolds number on stalling pressurerise coefficient (CpD). A function of the type f (x ) = a x b + C is used for the interpretation of Fig. 15. The coefficients of the function are: Fig. 13 Effect of tip clearance on stalling pressure-rise coefficient (CpD). Figure 14 shows the effect of axial-spacing on stalling pressure-rise coefficient (CpD). • The polynomial coefficients are listed below a0 a1 a2 a3 1.21683e00 -1.00986e01 2.424416e02 -3.38124e03 a4 a5 b c -101.8 -0.6767 1.041 • Calculation of blade angles Various angles at the inlet and outlet of the blade are shown in Fig. 16. 2.20418e04 -5.35103e04 The axial-spacing between rows is given by: ΔZ = 0.2 C a (43) 8 Ksh Blade Type 0.7 DCA 1.0 65-SERIES 1.1 C- SERIES 2 ⎛t⎞ ⎛t⎞ ⎛t⎞ k it = −0.0214 + 19.17⎜ c ⎟ − 122.3 ⎜ ⎟ + 312.5 ⎜ ⎟ ⎝ ⎠ ⎝c⎠ ⎝c⎠ 3 (45) i 010 = (0.0325 − 0.0674σ ) + (− 0.002364 + 0.0913σ )α 1 + (1.64e − 05 − 2.38e − 04σ )α 12 n = (− 0.063 − 0.02274σ ) + (− 0.0035 + 0.0029σ )α 1 − (3.79e − 05 + 1.11e − 05σ )α 12 Fig. 16 Various angles at the inlet and outlet of the blade. • Calculation of the deviation angle It is the difference between outlet blade-angle and outlet flow-angle. It arises from a combination of two effects. First, the flow is decelerating on the suction surface and accelerating on the pressure surface as it approaches the trailing edge. As a result of that, the streamlines are diverging on the suction surface and converging on the pressure surface so that the mean flow-angle is less than the blade angle. Second, the rapid boundary-layer growth on the suction surface towards the trailing edge pushes the streamlines away from the surface. The correlation for the deviation angle is given by: • The blade angles are α'1 = α1 – γ α'2 = α2 – γ Where, α1 is the blade inlet angle and α'1 is the flow inlet angle, α'2 is the blade outlet angle, α2 is the flow outlet angle and γ is the stagger angle. i = α1- α'1 δ= α'2- α2 θ δ = mc + x σ Where, i is the incidence angle which is the difference between the flow inlet angle and the blade inlet angle, δ is the deviation angle which is the difference between the flow outlet angle and the blade outlet angle. (46) δ (i = i ref ) = k sh k δ t δ 010 + mθ ⎛ ⎛t ⎞ k δ t = 0 . 0142 + 6 . 172 ⎜ c ⎟ + 36 . 61 ⎜ ⎝ ⎠ ⎝ The fluid deflection and the camber angles are defined by (47) (i 010 θ ) t ⎞ ⎟ c⎠ 2 (48) δ 010 = (0.0443 + 0.1057 σ ) + (0.0209 − 0.0186 σ )α 12 (− 0.0004 + 0.00076 σ )α 13 θ = α'1 + α'2 ε = α1+ α2 = (i + α'1) + (α'1 – δ) = ( α'1 + α'2) + (i - δ) m = m b =(θ + i -δ) ' (49) α 2 1 + 2 . 538 e − 03 • Calculation of the incidence angle − 1 . 3 e − 06 α Incidence is the difference between the inlet blade-angle and the inlet flow-angle. As the fluid flows towards the leading edge, it experiences "induced incidence". There is a pressure and a suction surface at a given blade. This difference of pressure changes the ingoing flow angle as it approaches the leading edge. The correlation for the incidence angle is given by: m' is different based on the blade type, DCA, C-series or a 65-series i ref = k sh k it i 010 + n θ (i 010 , θ ) 1 + 4 . 221 e − 05 α b = 0 . 9655 3 1 For a 65-series m = 0.17 − 3.33e − 04(1− 0.1α1)α1 ' (49.a) For DCA, C-series (44) ' 2 m = 0 . 249 + 7 . 4 e − 04 α 1 − 1 . 32 e − 05 α 1 (49.b) Ksh and kit are corrections factors for blade shape and thickness, respectively, Ksh differs whether the blade is a DCA,65-series or a C series [4]. 3 . 16 e − 07 9 α 13 By applying Buckingham's π-theorem and applying dimensional analysis, Eq. 50 may be simplified to the following dimensional form: II.2 Design Optimization of Axial-Flow Compressor Once we get the geometry supplied by the program of the axial-flow compressor design-point efficiency, its geometry is altered to maximize efficiency at the designpoint. The structure of the optimizing program is shown in Fig. 17. η tt = ⎛ f ⎜⎜ φ ,ψ , R , w1 , c 2 , M 1 , M 2 , R em , ζ U U ⎝ R ⎞ , ζ s ⎟⎟ ⎠ (51) Where M1 and M2 are the rotor and stator exit mach numbers that are defined as: M1= W1 a1 M2 = C2 a2 (52) Rem is the stage Reynolds number based on mean radius U rm (53) Rem = ζ υ , are the rotor and stator loss coefficients expressed R ζs in terms of the exit velocities C2 and w3 relative to the blade rows. Δp ζ R = 1 oR ρ W 12 2 ζs= Δ pos 1 ρ C 22 2 (54) φ , ψ are the flow and work coefficients defined as φ = Cx U Ψ= Δ ho (55) U • Independent design variables Fig.17 Structure of the optimizing program of the axialflow compressor. The designer is free to select the design duty coefficients ( φ , ψ). As these duty coefficients have a profound effect upon the stage efficiency ηtt even with optimum aerodynamic design. φ and ψ control the shape of the velocity triangles and thus the flow environment within which the blades operate. Also, the degree of reaction (R) has a direct control over velocity triangle shape and hence efficiency. By applying dimensional analysis for a single stage and making the following assumptions: Constant axial velocity Cx. Constant mean radius rm = 1/2(rh + rt). Identical velocity vectors C1 and C3 at entry to and exit from the stage at the mean radius rm. 1. 2. 3. The efficiency ηtt of this stage is dependent upon the following variables, [9]: ⎛ Δ h o , h1, h 2 , h 3 ω , r m , c x , w 3 ,⎞ (50) ⎟ η = f⎜ tt ⎜c2,μ,ρ,a ⎝ 2 ,a3,Δ • Dependent design variables affecting (ηtt) Experimental cascade tests show that the loss coefficients ζ R , ζ s are themselves dependent upon blade p or , Δ p os ⎟⎠ • Thermodynamic variables. The stage stagnation enthalpyrise Δho determines the specific work input and signifies stage loading. The specific enthalpies h1, h2 and h3 typify the progression in energy transfer through the stage. All four are independent variables. • Speed and size. Both are independent variables. • Velocity triangles. Four velocities are required to determine the shape of the velocity triangles these are the blade speed U = rm ω, Cx as an independent variables, C2, W1 are dependent variables. • Properties of working substances. The dynamic viscosity μ, density ρ and speeds of sound a1, a2 depend on the physical and thermodynamic properties of the gas. • Losses. The stator and rotor losses from all sources (profile drag, tip clearance loss, etc.) are lumped into stagnation pressure losses Δpos and Δpor. row Reynolds number and inlet Mach number. We would also expect that loss levels to be directly influenced by the velocity triangle environment within which the blades have to operate and hence to depend upon φ , ψ and R. We can express this through [9], ζ R ζ s = f 1 (φ ,ψ , R , Re R , M 1) = f 2 (φ ,ψ , R , Re s , M 2 ) (56) Where, the blade row Reynolds numbers ReR and Res are based on rotor and stator blade chords lR and ls. W 1l R Re R = υ C2 ls Res = υ 10 (57) Equation 51now is simplified into η tt = f (φ ,ψ , R , , ζ R , ζ s ) η tt =1− (58) 1 ⎛ 2 1 ⎜φ + 2ψ ⎝ 4 1. The stage duty coefficients ( φ , ψ). 2. The blade-row loss-coefficients The initial selection of the stage duty coefficients ( φ , ψ) is crucial. Thus, we could rewrite Eq. 64in the form Equation 58 can be converted into a more useful analytical form. By assuming for the moment a fixed reaction value R = 0.5. From h0 – S diagram, Fig. 18, by defining the stagnation enthalpy loss due to irreversibility into η tt = 1 − f c (φ ,ψ )(ζ R + ζ s ) (59) (Δp)loss, Eq. 63 Substituting the value of W1/U and C2/U into Eq. 63, we have (Δ p 0 )loss Hence, the total to total efficiency. ρU (Δ h0)loss (Δ p0)loss 1 ⎛⎜ (Δ p0)loss ⎞⎟ (61) h −h = 1− = 1− η tt = 03s 01 = 1 − ρ Δh0 ψ ⎜ ρU2 ⎟ Δ h0 h03 − h01 ⎝ ⎠ 1 2 ρU2 2 2 ζ R 2 = 1 2 2 ζ R 2 1 ⎛ w1 ⎞ ⎛C ⎞ ⎜ ⎟ + ζ s⎜ 2 ⎟ = 2 ⎝U ⎠ ⎝ U ⎠ 2 ⎡ ⎢φ 2 + ⎛ R + ψ ⎞ + 1 ⎜ ⎟ ⎢ 2 2 ⎠ ⎝ ⎣⎢ ζ s (67) 2⎤⎤ ⎡ ⎢φ 2 + ⎛⎜ 1 − R + ψ ⎞⎟ ⎥ ⎥ ⎢ 2 ⎠ ⎥⎦ ⎥⎥ ⎝ ⎣ ⎦ The total to total efficiency then follows by substituting into Eq. 61 to get (62) Substitution of Eq. 54 in Eq. 61results in the dimensionless loss. 2 (66) ⎠ The loss coefficients for the rotor ζ R and stator ζ s have been defined by Eq. 54 and the total stage loss From the conventional definition of ηtt = stagnation enthalpy rise for an ideal stage/stagnation enthalpy rise for the actual stage ⎛ w1 ⎞ 1 ⎛ C2 ⎞ ⎛⎜ ζ R + ζ s ⎞⎟⎛ 2 1 2⎞ + ⎟ + ζ s⎜ ⎟ = ⎜ ⎟⎜⎝φ 4 (1+ψ ) ⎟⎠ 2 2 U U ⎝ ⎠ ⎝ ⎠ ⎝ ⎠ )2 ⎞⎟ • Stage losses and efficiency (60) ζ R⎜ ( minimized by the careful blade profile design unless the duty coefficients ( φ , ψ) and velocity triangles are badly chosen in the first place, resulting in an excessive value of fc. The stage stagnation enthalpy rise is given by (Δ p0)loss = 1 1 ⎛ 2 1 ⎜φ + 1+ψ 2ψ ⎝ 4 ζ R and ζ s are normally used to represent cascade loss coefficients. We need to pin into all other frictional losses such as tip leakage and secondary losses related to the rotor and stator. From the stage performance analysis, the inherent aerodynamic loss character tics of the blades can be summarized [9]. From Eq. 66 fc depends upon duty coefficients ( φ , ψ) and thus the velocity triangle environment into which the blades are immersed. fc is called a "Weighting Coefficient" as it gives weight to the aerodynamic loss coefficients ζ R and ζ s which can be Fig. 18 T-S and h0-S diagrams for an axial-compressor stage. Since, (Δ p 0) = (Δ p 0 R ) + (Δ p 0 s ) loss loss loss (65) Where, the loss-weighting coefficient ( fc) is given by f c (φ ,ψ ) = Δ h0 = h03 − h01 ζ R and ζ s (i.e., blade- row aerodynamic). • Simple analytical formulation for the total to total efficiency of a compressor stage = h 03 − h 03 s (64) ⎠ Equation 64 is equivalent to the parametric Eq. 58 derived from the dimensional analysis for a 50% reaction. But it is in the much more useful explicit form of an analytical relationship which shows how ηtt depends upon the various dimensionless groups. From this, we can deduce that the efficiency of a 50% axial-compressor stage is dependent upon two main factors: Thus, the efficiency of an axial-compressor stage depends upon five dimensionless parameters which are sufficient to account for all the 15 items listed in Eq. 50Of these parameters, just three may be independently selected by the designer, namely φ , ψ and R. The loss coefficients themselves are also dependent upon the duty parameters φ , ψ and R but in addition are influenced by Reynolds number and Mach number. (Δ h 0 )loss (1+ψ )2 ⎞⎟ (ζ R + ζ s ) η tt = 1 − ⎧ 1 ⎪ ⎨ζ 2ψ ⎪ ⎩ 2⎤ ⎡ ⎢φ 2 + ⎛⎜ R + ψ ⎞⎟ ⎥ + ζ R⎢ 2 ⎠ ⎥⎦ ⎝ ⎣ 2⎤ ⎫ ⎡ ⎢φ 2 + ⎛⎜1− R + ψ ⎞⎟ ⎥ ⎪⎬ s⎢ 2 ⎠ ⎥⎦ ⎪ ⎝ ⎣ ⎭ (68) Eq. 68 is consistent with Eq. 61 as a result of linking stage duty ( φ , ψ) and reaction R to velocity triangles and thus to stage aerodynamics and thermodynamics. (63) Introducing Eq. 63 into Eq. 61,we have 11 • Optimum reaction III. Results and Discussions III.1 Results of Design Program For any prescribed ( φ , ψ) duty, we may estimate the stage reaction R, which will produce maximum efficiency. Eq. 68 can be written as. (69) η tt = 1 − L At first we summarize the main steps in the design procedure described in the analysis section. Having made appropriate assumption about the axial velocity, it is possible to calculate the annulus area at the inlet and outlet of the compressor and calculate the air angles required for each stage at the mean diameter. Then, by the use of vortex theory, the air angles can be calculated at various radiuses from root to tip. Throughout this work, there was a limitation on blade stresses; rates of diffusion and Mach number that were not exceeded. The results of the program were validated using the data of Ref. [6]. The compressor of the present study is a 15-stage axial compressor with 122 kg/s of air at ambient pressure of 1.013 bar and temperature 288 K, pressure ratio 20 and polytropic efficiency of 90%. Tables 1-5 show the present calculated values and the relative differences in comparison to the data of Ref. [6]. There is a good agreement as far as dimensions are concerned and a reasonable agreement in the other parameters. This may be attributed to some difference in design assumptions. The biggest differences between the present results and those of Ref. [6] are noticed in Table 5. The difference in the inlet stator angle may reach about 7%. Figures 19 and 20 show the rise of both the static pressure and temperature through the compressor stages, respectively. Figures 21-23 show the variation of air angles, degree of reaction, rotor/stator exit Mach number from root to tip for a selected stage (stage 10). In Fig. 21, the radial variation of air angles of the rotor shows a change in fluid deflection for a considerable twist along the blade height to ensure that the blade angles are in agreement with the air angles. In Fig. 22, the stator deflection is less in comparison to the rotor deflection due to the nature of building-up pressure in stator blades. In Fig. 23, the degree of reaction increases from root to tip, which indicates a high mass flow-rate per unit blade-height and thus plays an important role in to raising the stage efficiency. Figures 24 and 25 show the rotor and stator end wall, profile and total losses. Profile losses are contributed to boundary-layer separation while end-wall losses are mainly due to secondary flow effects and mixing for the rotor. The profile and end-wall losses increase through the stages with the result of an increase in total losses due to the increase in the work that is required to accomplish fluid turning and raising the pressure through different stages as well as the generation of entropy. At the stator, the end-wall and profile losses decrease, resulting in a decrease in total losses due to the diffusing working nature of the stator blades. Where, L is given by L= 2 2 ⎧ ⎡ ⎡ ψ ⎞ ⎤⎥ ψ ⎞ ⎤⎥ ⎫⎪ 1 ⎪ ⎢ 2 ⎛ 2 ⎛ ⎢ + + + + 1 − + R R ⎟ ζ s ⎢φ ⎜ ⎟ ⎬ ⎨ζ φ ⎜ 2ψ ⎪ R ⎢ 2 ⎠ ⎥⎦ 2 ⎠ ⎥⎦ ⎪ ⎝ ⎝ ⎣ ⎩ ⎣ ⎭ (70) The minimum loss and therefore maximum efficiency with respect to reaction R follows from ⎧ ∂L ⎫ (71) =0 ⎨ ⎬ ⎩ ∂R ⎭φ ,ψ Where φ and ψ are kept constant. If we assume that the loss coefficients are weak function of R and may be assumed constant also, then Eq. 71 yields to ψ R optimum = 2 (ζ s − ζ R )+ ζ s ζ s +ζ R (72) One possible solution to this which is true for all values of ψ is R = 0.5 and ζ s = ζ R . Although the stator and rotor velocity triangles are identical for this condition of 50% reaction, in reality there will be a difference in the two loss coefficients. Even so the strong indication is that 50% reaction will be close to optimum [9]. • Optimum ψ for a given φ and R Alternatively, we may search for ψ value leading to minimum loss for given φ and R values by writing (73) ⎧ ∂L ⎫ ⎨ ⎬ =0 ⎩ ∂ψ ⎭φ , R Resulting in ψ optimum = 2 φ 2 + 1 + R (R − 1 ) 2 Where, we have also assumed that ζ s and (74) ζ R are independent of ψ. Two stages of special interest are the 50% reaction stages which we have already considered and the 0% reaction or "impulse stages". For these two reactions Eq. 74 becomes 2 (75) = 4φ + 1 ψ optimum ψ optimum = 2 4φ + 2 Table 1: Comparison of the present (AFCP) results and the data of Ref. [6] for the compressor tip radius. In practice the stator and rotor loss coefficients ζ s and ζ R do vary with both φ and ψ and form experimental tests the sensible design for ψ lies between the two values. 2 (76) = 0 .185 4 φ + 1 ψ Compressor Tip Radius (mm) Present Ref. [6] Diff. (%) Stage Row (AFCP) 1 0.524 0.528 0.773 1 2 0.513 0.513 0.024 3 0.505 0.507 0.416 1 0.505 0.507 0.416 2 2 0.496 0.5 0.799 3 0.490 0.494 0.749 3 1 0.490 0.494 0.749 opt ., exp ψ max = 0 .32 + 0.2φ 12 4 5 6 7 8 9 10 11 12 13 14 15 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 0.483 0.479 0.479 0.473 0.470 0.470 0.471 0.468 0.468 0.464 0.462 0.462 0.458 0.457 0.457 0.453 0.452 0.452 0.449 0.449 0.449 0.446 0.445 0.445 0.443 0.443 0.443 0.441 0.440 0.440 0.438 0.438 0.438 0.437 0.436 0.436 0.435 0.435 0.489 0.484 0.484 0.480 0.476 0.476 0.474 0.470 0.470 0.467 0.464 0.464 0.462 0.460 0.460 0.457 0.455 0.455 0.453 0.452 0.452 0.450 0.449 0.449 0.448 0.447 0.447 0.446 0.445 0.445 0.444 0.443 0.443 0.443 0.442 0.442 0.441 0.441 1.187 1.023 1.023 1.405 1.221 1.221 0.66 0.357 0.357 0.665 0.441 0.441 0.83 0.723 0.723 0.784 0.599 0.599 0.79 0.768 0.768 0.884 0.816 0.816 1.094 0.991 0.991 1.215 1.084 1.084 1.265 1.111 1.111 1.48 1.308 1.308 1.644 1.457 7 8 9 10 11 12 13 14 15 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 0.362 0.362 0.367 0.369 0.369 0.373 0.374 0.374 0.377 0.378 0.378 0.381 0.382 0.382 0.385 0.385 0.385 0.388 0.388 0.388 0.390 0.391 0.391 0.392 0.393 0.393 0.394 0.394 0.372 0.372 0.375 0.378 0.378 0.380 0.383 0.383 0.385 0.387 0.387 0.389 0.390 0.390 0.392 0.393 0.393 0.394 0.395 0.395 0.396 0.397 0.397 0.397 0.398 0.398 0.398 0.399 2.763 2.763 2.247 2.545 2.545 1.982 2.402 2.402 2.008 2.250 2.250 1.986 2.032 2.032 1.871 1.967 1.967 1.633 1.768 1.768 1.501 1.664 1.664 1.201 1.387 1.387 0.975 1.177 Table 3: Comparison of the present (AFCP) results and the data of Ref. [6] for root-mean-square radius. Compressor Root Mean Square Radius (mm) Present Ref. [6] Diff. (%) Stage Row (AFCP) 1 0.415 0.421 1.445 1 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 2 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 3 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 4 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 5 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 6 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 7 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 8 2 0.415 0.421 1.445 3 0.415 0.421 1.445 1 0.415 0.421 1.445 9 2 0.415 0.421 1.445 3 0.415 0.421 1.445 Table 2: Comparison of the present (AFCP) results and the data of Ref. [6] for the compressor hub radius. Compressor Hub Radius (mm) Present Ref. [6] Diff. (%) Stage Row (AFCP) 1 0.264 0.274 3.614 1 2 0.285 0.300 5.142 3 0.299 0.310 3.604 1 0.299 0.310 3.604 2 2 0.314 0.321 2.329 3 0.323 0.332 2.923 1 0.323 0.332 2.923 3 2 0.333 0.339 1.792 3 0.339 0.346 2.065 1 0.339 0.346 2.065 4 2 0.347 0.351 1.159 3 0.351 0.357 1.664 1 0.351 0.357 1.664 5 2 0.350 0.360 2.767 3 0.354 0.364 2.905 1 0.354 0.364 2.905 6 2 0.359 0.368 2.365 13 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 10 11 12 13 14 15 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.415 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 0.421 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 1.445 Table 5: Comparison of the present (AFCP) results and the data of Ref. [6] for the compressor inlet blade angle. Stage 1 2 3 4 5 Table 4: Comparison of the present (AFCP) results and the data of Ref. [6] for the De Haller Parameter. Stage 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Row Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator De Haller Parameter Present Ref. [6] (AFCP) 0.739 0.739 0.77 0.808 0.734 0.744 0.765 0.752 0.73 0.744 0.761 0.752 0.726 0.745 0.756 0.753 0.721 0.746 0.751 0.750 0.717 0.741 0.746 0.745 0.717 0.737 0.746 0.740 0.713 0.732 0.741 0.735 0.709 0.727 0.736 0.730 0.705 0.723 0.73 0.728 0.701 0.722 0.725 0.726 0.697 0.721 0.72 0.723 0.693 0.719 0.714 0.720 0.69 0.717 0.709 0.716 0.686 0.715 0.703 0.700 6 7 Diff. (%) 8 0.000 4.935 1.362 -1.699 1.918 -1.183 2.617 -0.397 3.467 -0.133 3.347 -0.134 2.789 -0.804 2.665 -0.810 2.539 -0.815 2.553 -0.274 2.996 0.138 3.443 0.417 3.752 0.840 3.913 0.987 4.227 -0.427 9 10 11 12 13 14 15 14 Row Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Rotor Stator Inlet Blade Angle Present Ref. [6] (AFCP) 51.275 54.542 46.29 49.051 52.625 53.109 48.942 51.052 53.896 54.290 49.367 52.069 55.095 55.395 49.721 53.026 57.325 56.448 50.253 53.722 57.325 57.187 51.253 54.356 58.370 57.864 52.443 54.932 59.375 58.484 54.589 55.455 60.342 59.053 54.693 55.925 61.275 59.575 55.758 56.686 62.174 60.238 55.784 57.396 63.042 60.962 55.772 58.155 63.880 61.752 55.722 58.962 64.688 62.613 58.632 59.821 65.468 63.545 58.504 59.314 Diff. (%) 6.372 5.965 0.919 4.311 0.732 5.473 0.544 6.647 -1.531 6.903 -0.242 6.054 -0.867 4.746 -1.500 1.586 -2.136 2.253 -2.774 1.664 -3.114 2.890 -3.300 4.273 -3.331 5.815 -3.208 2.028 -2.937 1.385 Fig.19 Static pressure rise through the compressor. Fig.23 Stage (10), reaction and rotor/stator exit Mach number. Fig.20 Static temperature rise through the compressor. Fig.21 Stator angles and deflection of stage (10). Fig.24 Rotor profile, end-wall and total losses. Fig.22 Rotor angles and deflection of stage (10). Fig.25 Stator profile, end-wall and total losses. III.2 Results of the optimizing Program. 15 Table 6 summarizes the results that were obtained by the optimizing program using Eq. 76 for the selected values of ψ for φ =0.65. Table 6: Results of optimizing program. Case Ψ Pressure Ratio Efficiency (%) Max. Optimum Design Arbitrary 0.45 0.3 0.391 0.35 23.02 15.35 20 17.9 86.92 70.86 81.14 76.73 Figures 26 and 27 show the variation of isentropic efficiency and compressor pressure-ratio versus selected values of work coefficient. It can be seen that the isentropic efficiency and compressor pressure-ratio increase with the increase in work coefficient up to a certain limit. Further increase in wok coefficient causes the compressor stages to stall due the increased lading capacity of stages. Figures 28 and 29 show comparisons of total losses through compressor stages for different values of work coefficients for the rotor and stator, respectively. Generally, total losses decrease with the increase of the wok coefficient. Figures 30 to 33 illustrate the margin to surge for different values of work coefficient. It is shown that there is a reduction in the margin to surge with increase in work coefficient. The decrease is due to raising the loading capacity of stages with the increase in work coefficient. Figure 34 demonstrates increase in pressure ratio of compressor stages with the increase in the value of work coefficient due to the increase in loading capacity of stages. Figures 35 and 36 show the increase in camber angle with increase in work coefficient in the rotor and stator. The more the increase in work coefficient, the more the turning is required to control fluid deflection through the blades. Figures 37 and 38 illustrate improvements in the incidence angle in the rotor and stator with the increase in work coefficient. As the work coefficient increases, the margin to surge decreases. This is also illustrated in the deviation angle across the rotor and stator in Figs. 21 and 22. Fig.27 The pressure ratio versus work coefficient. Fig.28 Rotor total losses for all the compressor stages for different work coefficients. Fig.29 Stator total losses for all the compressor stages for different work coefficients. Fig.26 The isentropic efficiency versus work coefficient. 16 Fig.33 Koch surge limit for the compressor, ψ = 0.45. Fig.30 Koch surge limit for the compressor, ψ = 0.3. Fig.34 Pressure ratio of the compressor stages for different values of work coefficient. Fig.31 Koch surge limit for the compressor, ψ = 0.35. Fig.32 Koch surge limit for the compressor, ψ = 0.391. Fig.35 Rotor camber variation for different values of work coefficient. 17 Fig.39 Rotor-deviation variation for different values of the work coefficient. Fig.36 Stator camber variation for different values of the work coefficient. Fig.40 Stator-deviation variation for different values of the work coefficient. Fig.37 Rotor incidence variation for different values of the work coefficient. IV Conclusions Two computer programs have been developed for the design and optimization of an axial-flow compressor through a meridional analysis of the flow though the compressor with the assumption of axi-symmetric flow properties. These properties such as pressure, temperature and velocity are defined along streamlines at the entry and exit of each stage. The objective is to determine the shape of the flow passage, blade losses and blade angles given air mass flow, pressure ratio, number of stages, rotational speed and the geometrical data such as tip clearance, aspect ratio, thickness chord ratio, etc. Validation was carried out using the data of Ref. [6]. Generally, good agreement is achieved. The second program is a complement to the first program with the objective to maximize efficiency using the output data of the first program. An analytic relation between isentropic efficiency of the axial-flow compressor and the flow coefficient, the work coefficient, degree of reaction and different design parameters is obtained. The programs can be generalized of any type of axial-flow compressors. The results give general guidance for the optimum design of the axial-flow compressors. Fig.38 Stator incidence variation for different values of the work coefficient. 18 Nomenclature Symbol A a C CD CL Cm Cp Unit [m2] [m/s] [m/s] [-] [-] [m/s] [-] Cθ [m/s] c cp [m] [kJ/kg K] cv [kJ/kg K] Deq [-] fc H h h0 i l M2 [-] [m] [kJ/kg] [kJ/kg] [°] [m] [-] M3 [-] Ma m N p p0 R Re r S s T T0 t [-] [kg/s] [rev/s] [bar] [bar] [J/kg K] [-] [m] [kJ/kg] [m] [K] [K] [m] U W Wθ [m/s] [m/s] [m/s] Description Area Speed of sound Absolute velocity Drag coefficient Lift coefficient Meridional velocity Static pressure rise coefficient Tangential absolute velocity Chord Specific heat at constant pressure Specific heat at constant volume Equivalent diffusion ratio Weighting coefficient Blade height Static enthalpy Stagnation enthalpy Incidence angle Chord Rotor exit Mach number Stator exit Mach number Mach number Mass flow Rotational speed Static pressure Stagnation pressure Gas constant Reynolds number Radius Entropy Staggered spacing Static temperature Stagnation temperature Maximum blade thickness Blade velocity Relative velocity Tangential relative Velocity ζR : Rotor loss coefficient ζs : Stator loss coefficient Ø : Duty coefficient φ : Flow coefficient γ : Stagger angle μ : Dynamic viscosity ω : Angular velocity ρ : Density Abbreviations AFCP CFD DF EES IGV : Axial-Flow Compressor Program : Computational Fluid Mechanics : Diffusion Factor : Engineering Equation Solver : Inlet Guide Vanes Acknowledgments The fourth author expresses his thanks to his supervisors for their encouragements, advices and help to complete this work. References [1] J. R. Barbosa, "A Stream Line Curvature Computer Program for Performance Prediction of Axial Flow Compressors", Ph. D. Thesis, Cranfield Institute of Technology, England, 1987. [2] A. D. Carter, S. Hughes, and P. Hazel, "A Note on the High Speed Performance of Compressor Cascades", NTGE, December 1948. [3] M. V. Casey, "A Mean-Line Prediction Method for Estimating the Performance Characteristic of an Axial Compressor Stage", Institution of Mechanical Engineers Conference Proceedings, Switzerland, C264/87, 273285, 1987-6. [4] J. D. Denton, Turbomachinery Course, Whittle Laboratory, Deparment of Engineering, University of Cambridge, 2004. [5] S. L. Dixon, "Fluid Mechanics and Thermodynamics of Turbomachinery", 5th Edition, Elsevier Butterworth– Heinemann, 2004. Greek α1, α3 : Inflow angle α2 : outflow angle β1 : Relative inflow angle β2 : Relative outflow angle δ : Deviation angle ψ : Work coefficient ηtt : Stage efficiency [6] N. Falck, "Axial-Flow Compressor Mean-Line Design", Master Thesis, Lund University, Sweden, 2008. [7] W. Jansen, and W. C. Moffatt, "The off-Design Analysis of Axial-Flow Compressors", Journal for Engineering for Power, Vol. 89, No. 4, 1967. [8] C. C. Koch, "Stalling Pressure Rise Capability of AxialFlow Compressor Stages", Aircraft Engine Group, General Electric Co., 1981. [9] R. I. Lewis, "Turbomachinery Performance Analysis", 1st Edition, Butterworth-Heinemann, 1996. 19 [10] S. Lieblein, F. C. Schwenk, and R. L. Broderick, "Diffusion Factor for Estimating Losses and Limiting Blade Loadings in Axial-Flow-Compressor Blade Elements", NACA RM E53DO1, 1953. [11] H. I. H. Saravanamuttoo, G. F. C. Rogers, H. Cohen, and P. Straznicky, "Gas Turbine Theory", 5th Edition, Pearson Prentice Hall, 2001. [12] N. Seyb, "Design and Prediction Compressor", Cranfield University, 2001. of Axial [13] R. J. S. Teinke, "STGSTK - A Computer Code for Predicting Multistage Axial-Flow Compressor Performance by A MeanLine Stage-Stacking Method", Paper 2020-NASA, 1982. [14] P. I. Wright, and D. C. Och Miller, "An Improved Compressor Performance Prediction Model, ACGI, DIC", Rolls-Royce, Derby, 1991. [15] Softwaretopic.informer.com 20

© Copyright 2026