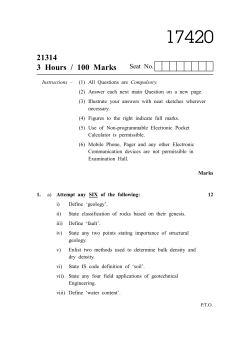

The Mechanics of Soils and Foundations, Second Edition