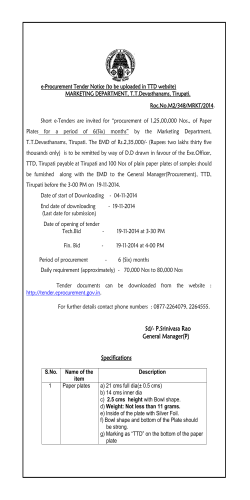

Furniture Tender for Anaj Bhawan.