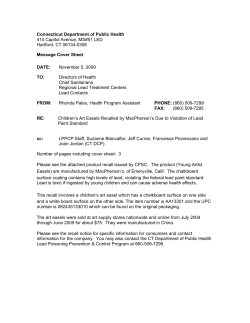

Document 75066