C:\M Drive\TIGER and FLEX Family MANUALS\Rasco Manuals

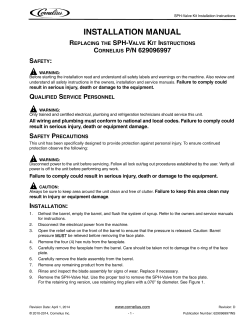

Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual for Kit No. 814-322-10 Revision 0514 Documentation Part No. 573-117-00 LIMITED REPRODUCTION RIGHTS This document may be reproduced by a Teradyne Customer solely for internal use with authorized systems by operators who have agreed to observe this restriction. Any copy of this document, or portions thereof, must contain the copyright and proprietary rights notice as stated on the original. Copyright 2005 Teradyne, Inc. Printed in the U.S.A. The material in this document is subject to change without notice. Teradyne, Inc. assumes no responsibility for any errors which may appear in this document. RESTRICTED RIGHTS LEGEND Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b) (3) (ii) of the Rights in Technical Data and Computer Software clause of DFARS 52.227-7013. Teradyne, Inc. 321 Harrison Avenue Boston, MA 02118 About this Manual Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual This manual provides installation instructions for a Rasco SO1000T material handler interface. The material in this manual is being provided for informational purposes and is subject to change without notice. Additional Information Further information regarding the Tiger Test System can be found in the following Teradyne manuals: Tiger Signal Solutions CD pn 553-702-70 Tiger Site Preparation Guide pn 553-702-00 Tiger Installation and Checkout Guide pn 553-702-01 Further information regarding the FLEX Test System can be found in the following Teradyne manuals: FLEX Signal Solutions CD pn 553-703-00 FLEX Site Preparation Guide pn 553-703-01 FLEX Installation and Checkout Guide pn 553-703-02 Further information regarding the microFLEX Test System can be found in the following Teradyne manuals: microFLEX Signal Solutions CD pn 553-705-00 microFLEX Site Preparation Guide pn 553-705-01 microFLEX Installation and Checkout Guide pn 553-705-02 Further information regarding the ultraFLEX Test System can be found in the following Teradyne documentation: UltraFLEX Signal Solutions CD pn 553-706-00 UltraFLEX Site Preparation Guide pn 553-706-01 Revision History Manual Name: Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Part Number: 573-117-00 _______________________________________________________________________ Revision Date Reason for Change 0514 Release Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Table of Contents 1 2 3 4 5 6 7 Overview ......................................................................................................................... 3 Configurable Interface Bills of Material (BOM) ................................................................ 5 Mounting the Insert Plate on the Interface Assembly Plate ............................................ 7 Installing Spacers on the Interface Assembly Plate ........................................................ 9 Installing Rough Guide Pins on the Interface Assembly Plate ........................................ 11 Installing the Interface Assembly Plate on the Handler ................................................... 13 Mounting and Aligning the Handler Interface Board (HIB) .............................................. 17 Appendix: Alternate Interface Assembly Orientation .............................................................. 19 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 1 Overview The configurable handler interface provides a docking solution for the Tiger and FLEX testers to a material handler. This interface is for use with the Tiger and FLEX - 0.200" thick handler interface board (HIB) (board manufacturing thickness tolerances can range between 0.182 and 0.210 inches). A. Unpack the Interface Assembly Kit Unpack and inspect the installation kit thoroughly for shipping damage. Verify the material against the packing list to make sure that all necessary components are in the kit. If there is damage or if there are discrepancies, report it immediately to your local Teradyne field service office before proceeding with the installation. B. Preparing the Tester Site Refer to the appropriate tester Site Preparation Guide for information on planning and preparing a tester site for the installation of the interface assembly. Because system layout is critical, Teradyne provides a recommended floor plan. Proper layout allows unhindered docking and ensures minimal strain on the manipulator cable bundle while providing service to the mainframe. If your test head/manipulator configuration and floor plans do not conform to those described in the guides below, and/or you require additional floor plans, contact the Teradyne Product Support Group (PSG). For information on floor strength requirements/floor plans, refer to • • Tiger Site Preparation Guide (pn 553-702-00) FLEX Site Preparation Guide (pn 553-703-01) 3 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 2 Configurable Interface Bills of Material (BOM) Teradyne Kit (pn 814-322-10) consists of the parts listed in Table 1. To install the Rasoc SO1000T handler interface (814-322-10) you will need the following kits: • Rasco SO1000T Interface Kit Table 1 • Base Configuration Interface Kit Table 2 Teradyne supplies the parts listed in Table 1 and Table 2. However, you will also need a customer supplied drill, a 1/4-1/2” tap wrench and a 3-70 in-lbs torque wrench for 5/64-1/2 inch fasteners. Table 1 Rasco SO1000T Interface Kit (pn 814-322-10) Quantity Part No. 1 811-960-10 1 573-117-00 Description Base Configuration I/F Kit 5.43mm Z-Stack Rasco SO 1000 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Table 2 Base Configuration I/F Z-Stack Rasco SO1000 (pn 811-960-10) (included in Table 1) Quantity Part No. Description 1 406-403-11 I/F Plate, Cat Config, Rasco low Z 3 480-018-17 Guide Pin 1 480-227-06 Spacer, groove, A pos, 0.324” thick 1 480-227-07 Spacer, groove, B pos, 0.324” thick 1 480-227-08 Spacer, groove, C pos, 0.324” thick 1 480-801-00 Stiffener, Interface Plate (long) 3 480-801-01 Stiffener, UFHC Interface Plate SHO (short) 3 804-887-10 Basic Assembly Groove 2 480-802-00 Spacer, Rasco, 5.43MM Z-Stack 8 470-196-09 Screw, CP FLT HD 6-32X3/8 BLK 30 470-165-12 Screw, CP SKT HD 6-32X1/2 SS Table 3 Basic Insert J750/FLEX Configurable Interface (pn 814-397-53) Quantity Part No. Description 1 811-968-03 J750 Configurable Basic Insert Assembly 5 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Note Use proper equipment and do not exceed the indicated torque values cited in the Installation section. Torque Specifications Torque values in Table 4 are used for steel (CRS/SS) screws in standard nuts, elastic stop nuts, cage nuts, rivnuts, and tapped holes in steel, and SEMS screws. These specifications can also be used for PEM nuts, PEM studs, and PEM standoffs in steel or aluminum stock. Table 4 Torque Specifications 6 STANDARD SCREW SIZE TORQUE (IN.-LB) 2-56 2-1/4 4-40 4-1/2 6-32 METRIC SCREW SIZE TORQUE Newton-meter(N-m) TORQUE (IN.-LB) M2 x 0.4 0.19 1.7 M2.5 x 0.45 0.39 3.5 9 M3 x 0.5 0.7 6.2 8-32 18 M3.5 x 0.6 1.1 10 10-32 30 M4 x 0.7 1.6 14 1/4-20 70 M5 x 0.8 3.3 29 5/16-18 140 M6 x 1.0 5.6 49 3/8-16 240 M8 x 1.25 13.5 119 1/2-13 500 M10 x 1.5 27 238 M12 x 1.75 47 415 M14 x 2.0 75 662 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 3 Mounting the Insert Plate on the Interface Assembly Plate The Z-stack (5.43mm) and the location of the mounting and aligning features between the Rasco dock plate and this interface requires a customized insert. The standard configurable basic insert (pn 814-397-50) cannot be used with this interface. The following insert must be used instead: Basic Insert, Tiger and FLEX, Rasco Low Z Interface (Teradyne part number 814-397-53). Instructions for mounting and attaching the insert plate to the interface assembly plate are given below (see Figure 1). 1) Mount and align the insert plate to the interface assembly plate. The two alignment pins on the bottom of the insert plate flange align with the hole and slot on the interface assembly plate. See Figure 1. 2) Secure the insert plate to the interface assembly plate by tightening the eight M5 captive screws to 29 inch-lbs. M5 Screws (X8) Insert Flange Alignment Pin Insert Plate Insert Flange Alignment Pin Interface Alignment Hole Interface Assembly Plate Interface Alignment Slot Figure 1 Attaching the Insert Plate to the Interface Assembly Plate 7 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 4 Installing Spacers on the Interface Assembly Plate Use the following procedure to install the spacers on the interface assembly plate. See Figure 2. 1) Turn the interface plate (with the insert) over so the handler side of the interface faces up. 2) Align the hole and slot on each spacer to the pins on the insert. 3) Attach the two spacers (pn 480-802-00) to the interface and the insert using the four 6-32 X 3/8-inch flat head screws (pn 470-196-09)(torque: 9 inch-lbs.). Note Make sure that the screws go into the spacer countersink screw holes so the screws are flush with or below the surface of the spacer. 4) Turn the interface plate (with the insert) over so the testhead side of the interface faces up. Screws (4 per spacer) Spacers (X2) Interface Assembly Plate Insert Figure 2 Installing Spacers on the Interface Assembly Plate and the Insert 9 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 5 Installing Rough Guide Pins on the Interface Assembly Plate Fasten the three rough guide pins (pn 480-018-17) to the interface assembly plate (torque: 24 inch-lbs.). See Figure 3. Basic Insert Rough Guide Pins Rough Guide Pin Interface Assembly Plate Figure 3 Mounting the Rough Alignment Guide Pins (Basic Insert Shown) 11 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 6 Installing the Interface Assembly Plate on the Handler Before You Begin Before starting the installation, verify that the proper mounting holes have been drilled into the handler. If the holes are not present, contact your Teradyne, Inc. representative for additional help. [239.725] 239.725 9.438 9.438 239.725 [239.725] 9.438 9.438 2X O.D. 3/16 4X 1/4-20 UNC - 2B 136.95 5.392 [92.50] ASCO ZERO Zero TO ALIGNMENT PINS 92.50 Rasco to 2X 3.642 Alignment Pins 2X 3.642 Rasco Docking Plate Zero 16.30 .642 to HIB Center Line 59.90 2X 2.358 ASCO DOCKING PLATE ZERO TO HIB CENTER LINE 279.40 2X 11.000 279.40 2X 11.000 Figure 4 Required Mounting Features Use the following procedure to install the interface assembly plate on the handler. See Figure 5 and Figure 6. Note Steps 1 through 3 require two people to perform. 13 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 1) Position the interface assembly plate next to the handler mounting surface (DIB Vertical Left, Swing Right Orientation). For alternate manipulator swing setup, refer to Appendix: Alternate Interface Assembly Orientation Interface Assembly Plate Pin Locations Handler Spacer A Mounting Holes (two on each side) Slot Hole Spacer C Figure 5 Exploded View of the Interface Assembly Plate Positioned Next to the Handler The side of the interface assembly plate with lettered markings (A, B and C) for the native groove spacers must face away from the handler. Marking C must be placed closest to the floor and markings A and B must be placed furthest from the floor. See Figure 6. 2) 14 Lift the interface assembly plate and position it so that the alignment pins on the handler fit into the hole and slot on the interface assembly plate. See Figure 5 and Figure 6. Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 3) Tighten the four captive 1/4-20 screws on the insert to 70 inch-lbs. V-Groove Spacer B V-Groove Spacer A 1/4-20 Captive Screws (X4) Basic Insert V-Groove Spacer C Figure 6 Interface Assembly Fastened to the Handler 15 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 7 Mounting and Aligning the Handler Interface Board (HIB) Instructions for mounting the handler interface board (HIB) to the basic insert plate (see Figure 7): Attaching the HIB to the Basic Insert Plate Assembly Use the following procedure to attach the HIB to the basic insert assembly plate. 1) Unscrew all four thumbnuts on the basic insert plate and put them in the open position. 2) Orient the HIB stiffener so that the round and slotted bushing are properly aligned to the corresponding pins on the basic insert plate. 3) Position the HIB on the basic insert plate and place the thumbnuts in the grooves on the HIB stiffener mounting brackets (see Figure 7). 4) Tighten (finger tight) the four thumbnuts by rotating them clockwise. This secures the stiffener to the basic insert plate (see Figure 7). Thumbnuts (X4) (in open position) A HIB and HIB Stiffener Basic Insert Plate Figure 7 Attaching the HIB and HIB Stiffener to the Insert Assembly Plate (Manual Mounting) 17 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Detaching the HIB from the Basic Insert Assembly Plate Use the following procedure to detach the HIB from the basic insert assembly plate (see Figure 7). 1) Loosen the four thumbnuts by rotating them counterclockwise. 2) Hold the HIB stiffener securely while sliding the thumbnuts out of the stiffener mounting bracket grooves. 3) Separate the HIB and HIB stiffener from the basic insert plate and store in a safe place. 18 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual Appendix: Alternate Interface Assembly Orientation If your floor plan or manipulator requires a DIB vertical right swing left manipulator orientation, follow the procedure below to convert from the DIB vertical left orientation to the DIB vertical right orientation. See Figure 8. V-Groove Location C V-Groove Location A V-Groove Location B Figure 8 Interface Assembly Plate in DIB Vertical Right Orientation Note Steps 1 and 3 require two people to perform. 19 Rasco SO1000T Handler Interface with a 5.43mm Z-Stack Installation Manual 1) Place the interface down on a flat surface. See Figure 9. DIB Vertical Left DIB Vertical Right DIB Vertical Left DIB Vertical Right DIB Vertical Left DIB Vertical Right DIB Vertical Left DIB Vertical Right Figure 9 Switching Orientation from DIB Vertical Left to DIB Vertical Right 2) Remove the four 1/4-20 captive screws from the holes marked, in the figure above, “DIB Vertical Left” and insert them into the holes marked, in the figure above, “DIB Vertical Right.” See Figure 10. 3) Rotate the interface assembly plate 180-degrees and reattach it to the handler per instructions in Section 6 of this manual. See Figure 10. V-Groove Location C V-Groove Location A V-Groove Location B Figure 10 Interface in DIB Vertical Right Orientation 20

© Copyright 2026