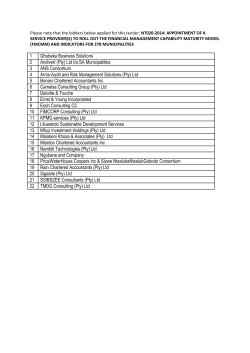

The Paste 2015 seminar preliminary programme is now available.

PASTE 2015 5–7 M ay 2015 | Pullman Cairns I nternational Hotel | Cairns, Queensland REGISTRATION BROCHURE Earlybird registration ends 23 March 2015 See inside for preliminary programme! In 1999 the ACG initiated the series of international seminars on paste and thickened tailings. This influential and respected annual event continues to provide a valuable forum for international tailings and mine waste practitioners to explore, learn and share advances in paste and thickened tailings and, increasingly important, water conservation and environmental stewardship. The ACG team looks forward to welcoming many previous seminar attendees and those interested to learn more about mine waste management to the 18th International Seminar on Paste and Thickened Tailings. KEY DATES Sunday | 3 May 2015 Monday | 4 May 2015 Rheology Fundamentals for Slurries and Pastes Short Course An Introduction to the Design of High Density Tailings Disposal Pipelines Short Course Tuesday | 5 May 2015 Wednesday | 6 May 2015 Thursday | 7 May 2015 Paste 2015 Seminar Mine Backfill System Design, Operation and Management Short Course PRINCIPAL SPONSOR MAJOR SPONSORS W W W. PA S T E 2 0 1 5 . CO M Friday | 8 May 2015 Site Visit: Chinova Resources Pty Ltd Osborne Mine PRELIMINARY PROGRAMME* DAY ONE | TUESDAY | 5 MAY 2015 07:00 REGISTRATION 08:30 Welcome and Introduction RJ Jewell, Paste 2015 Seminar Chair, Australian Centre for Geomechanics, Australia THICKENING (1) 08:40 KEYNOTE: Thickener modelling – from laboratory experiments to full-scale prediction of what comes out the bottom and how fast PJ Scales, AH Crust, SP Usher, The University of Melbourne, Australia 09:25 A novel method to locate and profile the bed of a thickener RD Cook, JL Johnson, WesTech Engineering, Inc., USA 09:45 Thickeners versus centrifuges – a coal tailings technical comparison S Meiring, PasteTech, Australia 10:05 Discussion 10:15 MORNING BREAK THICKENING (2) 10:45 Operational results and future trends of filtration technology in minerals processing J Palmer, Outotec Pty Ltd, Australia 11:05 Dewatering in a laboratory simulation of a multilayer deposit of in-line flocculated mature fine tailings E Rozina, S Mizani, M Malek, M Sanchez-Sardon, P Simms, Carleton University, Canada 11:25 The influence of slurry density on in situ density D Reid, Golder Associates Pty Ltd, Australia; AB Fourie, The University of Western Australia, Australia 11:45 Sarcheshmeh Copper Mine paste plant design, start-up and early operation overview S Javadi, B Pirouz, P Williams, ATC Williams Pty Ltd, Australia; A Zarabadi, HR Seif, National Iranian Copper Industries Co., Iran 12:05 Discussion 12:15 LUNCH RHEOLOGY (1) 13:15 Attributes of silica treatment on strength, physical properties and consolidation rates of fluid fine tailings RH Moffett, E.I. DuPont, USA 13:35 Evaluation of the rheology of pipehead flocculated tailings PT Slatter, KD Seddon, ATC Williams Pty Ltd, Australia 13:55 Polymer-modified tailings deposition – ongoing testing and potential storage efficiency opportunities TC Riley, D Reid, Golder Associates Pty Ltd, Australia; L Utting, BASF Australia Ltd, Australia 14:15 Why small-scale testing of reagents goes wrong PD Fawell, AD Costine, AF Grabsch, CSIRO Mineral Resources Flagship, Australia 14:35 Discussion 14:45 AFTERNOON BREAK RHEOLOGY (2) 15:15 Risk assessment methodology for paste and thickened tailings A Fernandez-Iglesias, ArcelorMittal Global R&D Asturias, Spain; A Correa, ArcelorMittal Mining, France; O Morton, ArcelorMittal Mining, UK; J Laine, R Luiña, G Martínez, University of Oviedo, Spain 15:35 Stability of a proposed steepened beach D Reid, J Boshoff, Golder Associates Pty Ltd, Australia 15:55 Research trends on thickening mining wastes J Laine, F Ortega, R Luiña, V Alvarez-Cabal, University of Oviedo, Spain 16:15 Management of bauxite residue in a temperate climate using mud-farming techniques MB Willan, Golder Associates (UK) Ltd, UK; GS Ghataora, The University of Birmingham, UK 16:35 Discussion 16:45 WELCOME FUNCTION *The preliminary programme is subject to change. For updates please visit www.paste2015.com W W W. PA S T E 2 0 1 5 . CO M PRELIMINARY PROGRAMME* DAY TWO | WEDNESDAY | 6 MAY 2015 CASE STUDIES – SURFACE DISPOSAL 08:30 KEYNOTE: The high-density thickened discharge tailings storage facility at Osborne Mine – a case history from inception to closure GI McPhail, SLR Consulting Australia Pty Ltd, Australia 09:15 Hillendale thickened tailings storage facility – from project to closure K Goss-Ross, Independent Tailings Consultant, South Africa 09:35 The Sar Cheshmeh thickened tailings scheme – a case study A Roshdieh, P Williams, KD Seddon, ATC Williams Pty Ltd, Australia 09:55 Discussion 10:05 MORNING BREAK TRANSPORT 10:35 Hydraulic driven piston pumps for the transport of pastes and slurries in the mining industry P Peschken, Putzmeister Solid Pumps GmbH, Germany; K Kivanc, Eti Bakir A.S, Turkey 10:55 Dredging of an active thickened tailings storage facility at the Ernest Henry Mine TG Fitton, Fitton Tailings Consultants, Australia; WJ Neumann, Neumann Contractors Pty Ltd, Australia 11:15 A comparison between long stroke (508 mm) and short stroke (356 mm) piston diaphragm pumps H Krimpenfort, MHWirth, Germany 11:35 Series connection of diaphragm piston pumps DM Nägel, R Gänsl, FELUWA Pumpen GmbH, Germany 11:55 Discussion 12:05 LUNCH UNDERGROUND ISSUES (1) 13:05 Stress analysis of underground pipeline with flexible couplings – unrestrained approach J Sabeti, A Asgarian, Hatch Ltd., Canada 13:25 Experimental study on the physical and mechanical properties of a cemented unclassified tailings backfill XC Yang, GS Liu, LJ Guo, Beijing General Research Institute of Mining & Metallurgy, China 13:45 Early curing age paste backfill exposures – the role of effective stress RL Veenstra, Glencore Australia Pty Ltd, Australia; AMC Mining Consultants (Canada) Ltd, Canada; MW Grabinsky, University of Toronto, Canada; WF Bawden, Mine Design Engineering, Canada 14:05 Gwalia Mine – backfill system operational review S Wilson, Paterson & Cooke (UK) Ltd., UK; J Snyman, Paterson & Cooke Consulting Engineers (Pty) Ltd, South Africa; M McGuinness, Paterson & Cooke Canada Inc., Canada; J Albrecht, J De Vries, St Barbara Ltd, Australia 14:25 Discussion 14:35 AFTERNOON BREAK UNDERGROUND ISSUES (2) 15:05 A comparison of two paste plants in India C Lee, Golder Associates Ltd., Canada; G Chatterjee, A Gandhe, Golder Associates Consulting (India) Pvt Ltd., India; BV Rao, A Nirvan, DP Ravikumar Hindustan Zinc Limited, India 15:25 Chemical technology case study in cemented paste backfill – Newmont’s Tanami Gold Mine R Salter, UGC BASF, Australia; A Flemmer, Newmont Tanami Operations, Australia; J Gelson, UGC BASF Asia Pacific, Australia; Z Martic, UGC BASF Global, Switzerland 15:45 Mobile paste backfill systems – a decade of work S Longo, A Quintero, D Kennard, Golder Associates Ltd., Canada 16:05 Acti-Gel®208 as an additive for paste and hydraulic backfill K Tarr, I Bedard, Natural Resources Canada, Minerals and Metals Sector, CanmetMINING, Canada; F Malek, Vale Canada Ltd., Canada; H Kim Active Minerals International LLC, Canada 16:25 Discussion 16:35 DAY TWO CLOSE 19:00 SEMINAR DINNER Following on from the first edition released in 2002 and the second in 2006, the ACG is producing the third edition of “Paste and Thickened Tailings – A Guide”. The revised edition will include the significant advances made in the field since 2006 and will include a number of new chapters. PASTE AND THICKENED TAILINGS – A GUIDE (THIRD EDITION) SPONSORS PLATINUM SPONSORS GOLD SPONSOR *The preliminary programme is subject to change. For updates please visit www.paste2015.com W W W. PA S T E 2 0 1 5 . CO M SILVER SPONSORS PRELIMINARY PROGRAMME* DAY THREE | THURSDAY | 7 MAY 2015 BEACHING 08:30 Practical observations in beach slope formation and application of the thin layer equilibrium model to observed data JA Wates, HA Venter, VT Dittle, RA Cooper, Fraser Alexander Pty Ltd, South Africa 08:50 Stochastic beach profile modelling KD Seddon, B Pirouz, ATC Williams Pty Ltd, Australia; TG Fitton, Fitton Tailings Consultants, Australia 09:10 Simulation of the meandering flow path of a beaching slurry using a random walk technique GI McPhail, SLR Consulting Australia Pty Ltd, Australia 09:30 Discussion 09:40 MORNING BREAK BEACHING AND TRANSPORT 10:10 A launder design method for thickened tailings TG Fitton, Fitton Tailings Consultants, Australia 10:30 Open channel transportation of thickened tailings S Javadi, RMIT University, Australia; PT Slatter, ATC Williams Pty Ltd, Australia; SN Bhattacharya, R Gupta, RMIT University, Australia 10:50 Recycling fine slurry – an alternative to paste for coarse rejects co-disposal in Queensland coal mines AD Thomas, NT Cowper Snr, Slurry Systems Pty Ltd, Australia; S Whitton, Mechanical Advantage Pty Ltd, Australia 11:10 Chuquicamata full-scale field deposition trial B Pirouz, S Javadi, P Williams, ATC Williams Pty Ltd, Australia; C Pavissich, ATC Williams Pty Ltd, Chile; G Caro Codelco, Chile 11:30 Discussion 11:40 LUNCH ABOVE GROUND DISPOSAL (1) 12:40 Characterisation of a thickened tailings beach KD Seddon, JK Albee, ATC Williams Pty Ltd, Australia 13:00 Optimisation and stabilisation of coal rejects at the Peabody Metropolitan Mine using Acti-Gel® 208 JH Worsley, JE Marsh, Active Minerals Australia Pty Ltd, Australia; R Patel, Peabody Energy Australia, Australia; SB Feldman, Active Minerals International, USA 13:20 Assessing the flow liquefaction susceptibility of cyclone underflow material J Boshoff, D Reid, Golder Associates Pty Ltd, Australia 13:40 Upstream stacking of thickened tailings at Neves Corvo R Lopes, Golder Associates Ltd., Canada; R Bahia, Golder Associates Portugal Unipessoal Lda, Portugal; M Jefferies, Golder Associates (UK) Ltd, UK; M Oliveira Somincor, Portugal 14:00 Discussion 14:10 AFTERNOON BREAK ABOVE GROUND DISPOSAL (2) 14:40 The impacts of using thickened tailings on water management and CAPEX of tailings storage facilities K Fabian, AECOM, USA; M Jacobs, Goldcorp Inc., Canada; A Hooshiar, E Ngwenya, AECOM, Canada 15:00 Managing high-density tailings disposal – deposition, water management and closure considerations S Kam, Golder Associates Ltd., Canada; D Yaschyshyn, N Hmidi, Goldcorp Canada Corp., Canada 15:20 Differential water footprint assessment – conventional versus paste tailings disposal A Fernandez-Iglesias, S Andres, ArcelorMittal Global R&D Asturias, Spain; R Luiña, D Pecharroman, V Alvarez-Cabal, University of Oviedo, Spain 15:40 Tailings co-disposal case study – art or science? A Beveridge, BASF Australia Ltd., Australia; P Mutz Murray Zircon Pty Ltd, Australia; D Reid, Golder Associates Pty Ltd, Australia 16:00 Discussion 16:10 Seminar Farewell and Announcements 16:30 SEMINAR CLOSING DRINKS AND NIBBLES *The preliminary programme is subject to change. For updates please visit www.paste2015.com W W W. PA S T E 2 0 1 5 . CO M PASTE 2015 SITE VISIT: CHINOVA RESOURCES PTY LTD OSBORNE MINE 8 May 2015 Osborne Mine is located in Northern Queensland, approximately 1,000 km inland from the eastern coast. It commenced operations in 1995 with the development of an open pit mine and in 1996 transitioned to underground mining. In 2015, Osborne will have been in operation for 20 years and will have mined 29 Mt of ore. The site has produced 672, 420 t of copper and 673,295 oz of gold. Osborne Mine produces about 112,000 t of tailings per month. In 2003, following progressive evaluation and development of a high density discharge tailings management system, Osborne implemented the first of two trial depositions forming advancing cones of deposited tailings within their TSF2 site. These trials proved successful and, following successful permit applications to the regulators, TSF2 was converted to high density thickened tailings discharge. The principle benefit of this change was in the reduction of construction costs for confining embankments. However, an additional major benefit lay in a reduction of make-up water volumes. The majority of water loss in the process water circuit occurs in the tailings system, as a result of evaporation. High density thickened discharge (HDT) provides a means for significantly reducing water losses, since, by recovering and reusing more water at the thickener and in the plant, less water is discharged onto the TSF – thus less water available for evaporation. HDT also enabled a significant improvement in operating costs. HDT is continuously modified and adjusted as ore from satellite mines has been brought in to supplement the diminishing Osborne Mine ore. Mineralogical influences of the supplementary ore significantly affected the thickening and beaching characteristics of the tailings slurry, particularly in the most recent operating period. However, through appropriate modifications and adjustments the benefits of high density thickened discharge have been retained. The resulting TSF landform is that of a shallow-sloped shedding mound so that there is no need to retain water on the TSF. Chinova has been proactive with ongoing site monitoring and rehabilitation with a view to shedding runoff to the environment. Their site plans include ensuring that the discharge water from the site will meet the stock-water guidelines and that the erosion gullies forming in TSF cover materials, or on the side slopes of confining embankments, will not result in exposure of the tailings over 500 years. Please contact the ACG for site visit details. VENUE | ACCOMMODATION Pullman Cairns International Hotel 17 Abbott Street Cairns, Queensland, 4870 Australia Tel: +61 7 4031 1300 Email: [email protected] www.pullmancairnsinternational.com.au Overlooking Cairns Harbour and the mountain hinterland and comprising 321 rooms, Pullman Cairns International provides accommodation to meet your requirements. Delegates attending the Paste Seminar in May 2015 will have access to discounted rates at the venue location. KEYNOTE SPEAKERS Dr Gordon McPhail Professor Peter J. Scales Technical Discipline Engineer SLR Consulting Australasia Pty Ltd Deputy Dean, School of Engineering The University of Melbourne “The high density thickened discharge tailings storage facility at Osborne Mine – a case history from inception to closure” “Thickener modelling – from laboratory experiments to full-scale prediction of what comes out the bottom, and how fast” W W W. PA S T E 2 0 1 5 . CO M PASTE 2015 SPONSORS AND EXHIBITORS PRINCIPAL SPONSOR MAJOR SPONSORS ELECTRONIC PROCEEDINGS SPONSOR INDUSTRY SPONSOR AUSTRALIAN TAILINGS CONSULTANTS TRADE EXHIBITORS W W W. PA S T E 2 0 1 5 . CO M ASSOCIATED EVENTS Rheology Fundamentals for Slurries and Pastes Short Course 3 May 2015 | Pullman Cairns International Hotel | Australia “Integral to process plant design is identification of the slurry system operating window that allows increased throughput while decreasing capital and operating costs. For any system involving thickening or paste production, understanding the material rheological characteristics is prerequisite to identifying this window and successful, optimal and reliable operation.” PROGRAMME* 08:00 Registration 08:30 How do we define a slurry/paste • Solids concentration • Density • Particle size distribution (PSD) • Particle morphology (shape) • Mineralogy/surface chemistry 10:00 Morning break 10:30 Slurry rheology/flow properties • Explanation of the following flow properties and an overview of what they mean in the ‘real’ world >> Yield stress >> Viscosity >> Shear rate dependence >> Time dependence • The effect of solids concentration, PSD, morphology on the flow characteristics of slurries ABOUT THE COURSE An understanding of slurry and paste rheology or fluid flow, dewatering including thickening and filtration and surface chemistry/ rheology interrelationships, is fundamental to slurry system design, operation and risk management. Although the situation has improved over recent years, investment into understanding slurry fundamentals is still often insufficient to mitigate against the risk of under or over design and poor operating performance. The course will focus on identifying what information is required, how to interpret measured data and how to apply to new system design and existing operations. Slurry rheology measurement • Yield stress measurement >> The vane method >> The slump test • Shear stress – shear rate (flow curve and viscosity) measurement >> Rotational methods including the ‘bucket’ rheometer >> Capillary/pipeloop testing • Laboratory versus pipeloop testing • Data extrapolation • Reading rheograms Attendees will learn about slurry physical and chemical properties, how flow properties or rheology are measured and how to meaningfully interpret rheological data for viscosity, yield stress, time dependence and dewatering information. The course will outline how to apply rheology and surface chemistry for pipeline transport and thickening equipment selection and optimal control and operation. PRESENTERS Flow models – communicating data • Types of flow models • How to use flow models • Slurry rheology measurement problems and pitfalls – examples and case studies Dr Fiona Sofrà Managing Director Rheological Consulting Services Pty Ltd Fiona is co-founder and managing director of Rheological Consulting Services Pty Ltd. Fiona is an expert in slurry handling and rheology. Fiona is focused on understanding the complex interrelationships that contribute to rheological phenomena in slurries and pastes, and translating these into relevant and valuable inputs for optimal and reliable plant operation. Professor Peter J. Scales Deputy Dean, School of Engineering The University of Melbourne Peter is Deputy Dean of the Melbourne School of Engineering and co-founder of Rheological Consulting Services Pty Ltd. Peter has over 25 years’ academic and industrial experience in particle processing, conducting research and consulting in the areas of slurry flow, particle dispersion, particle flocculation and separation technologies including thickening, filtration and centrifugation. Slurry rheology roadmap A systematic ‘decision tree’ approach for a testwork program to obtain data necessary for slurry system design and optimisation 12:30 Lunch 13:30 Slurry surface chemistry/rheology relationships • Zeta potential, ionic strength and clay chemistry explained • Modifying rheology using surface chemistry effects • Coal/clay controlled dispersion case study Dewatering • Compression rheology • Flocculation • Settling 15:00 Afternoon break 15:30 Thickening • Thickener types and selection criteria • Control of the thickener for optimal rheology Filtration • Filter types and selection criteria • Filtration control Discussion No course proceedings will be available for purchase. *This programme was correct at time of printing. For updates, please visit www.paste2015.com/events. 17:00 Course close W W W. PA S T E 2 0 1 5 . CO M ASSOCIATED EVENTS An Introduction to the Design of High Density Tailings Disposal Pipelines Short Course 4 May 2015 | Pullman Cairns International Hotel | Australia ABOUT THE COURSE The objective of the course is to provide attendees with an overview of the broad design principles of high concentration slurry pipelines used for the disposal of paste and thickened tailings. The course includes a brief overview of the hydraulic design of pump and pipeline systems by considering the interaction of the pipeline system and pump performance curves when pumping water. This provides the basis for understanding the differences between Newtonian and non-Newtonian pipeline systems. The concept of rheology and its importance in pump and pipeline design will be discussed, and the implications of pumping viscous slurries on equipment selection will be presented. On completion of the course, delegates will have an appreciation of the requirements for the design of high density tailings slurry pipelines. TARGET AUDIENCE The course is aimed at mining professionals who have limited exposure to the design of slurry pipelines and wish to obtain further understanding of the basic design principles required for high density pumping systems. PRESENTERS PROGRAMME* Dr Angus Paterson Managing Director Paterson & Cooke, South Africa Angus is the managing director of the Cape Town office of Paterson & Cooke, having founded the company together with Dr Robert Cooke in 1991. Angus has been directly involved in analysis and design of slurry transport systems since 1987 and has worked on slurry pipeline projects. These include long distance slurry pipelines, underground paste and backfill distribution systems and numerous conventional, thickened and paste tailings disposal systems. Andres Ortiz Managing Director Paterson & Cooke, Australia 07:30 Registration 08:00 Presenter: Dr Angus Paterson Introduction to pump and pipeline hydraulics • Water pipeline overview • Rheology and slurry flow behaviour 10:00 Morning break 10:30 Presenter: Andres Ortiz • Hydraulic design of high density slurry pipelines • Hydraulic grade line analysis • Pipeline system curve and pump performance curves 12:30 Lunch 13:30 Presenter: Paul Geraedts Andres is a mechanical engineer who has gained skills in mechanical, piping and pipeline engineering for mineral processing plants, power generation and oil & gas, with emphasis on slurry pipeline systems. Andres joined Paterson & Cooke in 2012. • Selecting pumps for high density pipeline systems • Effect of solids on pump performance • Influence of rheology on pump performance 15:00 Afternoon break 15:30 Presenters: Dr Angus Paterson, Andres Ortiz and Paul Geraedts Paul Geraedts Senior Project Engineer Paterson & Cooke, Australia Paul is a mechanical engineer who has over 19 years of experience in all aspects of slurry/concentrate pumping and pipeline engineering including hydraulics, slurry/paste rheology testwork and related mechanical equipment selection for slurry/concentrate preparation and disposal. Paul joined Paterson & Cooke in 2013. • 17:00 • Test work requirements for the design of high density slurry pipeline systems • Cost comparison of low and high density tailings disposal systems based on total cost of ownership Course close No course proceedings will be available for purchase. *This programme was correct at time of printing. For updates, please visit www.paste2015.com/events. W W W. PA S T E 2 0 1 5 . CO M ASSOCIATED EVENTS Mine Backfill System Design, Operation and Management Short Course 4 May 2015 | Pullman Cairns International Hotel | Australia ABOUT THE COURSE TARGET AUDIENCE Backfill is seldom recognised as a critical part of the mining cycle until it is too late. Poor design, inadequate comprehension of the materials, or under-sizing of the entire system can lead to unreliable fill delivery, or worse – no backfill placement at all. The course is aimed at mining professionals who have limited exposure to the design of paste backfill systems, or may be operating a system now and wish to obtain further understanding of the basic design principles. A sound understanding of the material properties and proven design fundamentals ensure a mine’s backfill system will be reliable and cost-effective. This course will briefly touch on backfill methods, and then focus on paste fill and the important relationships between system design, operation and management. The course objective is to provide participants with an overview of the fundamentals to be considered when effectively sizing, designing and operating mine paste fill systems. On completion of the course, delegates will have an appreciation of a best practice operation and the design and operational requirements of a safe and reliable paste backfill system. PROGRAMME* 08:00 Registration 08:30 Introduction Steve Wilson, Paterson & Cooke, UK 08:40 Backfill strength and geomechanics Dr Dave Stone, Minefill Services, Inc., USA PRESENTERS Chris Lee Managing Principal Golder Associates Ltd., Canada Chris has more than 20 years’ experience in hydraulic backfill, cemented rockfill, paste fill, and mine dewatering systems, as well as shaft sinking, crushing, materials handling, and other mining infrastructure design. Chris has been involved in developing plant conceptual and detailed design, equipment specification, bid analysis, and layouts, to commissioning and a successful start-up. • Why use paste backfill versus other backfill methods • How backfill strength requirements are determined • Calculation methods for backfill strength • Barricade design and best practices 10:00 Morning break 10:20 Plant design Chris Lee, Golder Associates Ltd., Canada Maureen McGuinness Senior Process Engineer Paterson & Cooke, Canada Maureen has worked in mining and milling for over 18 years and specifically in paste backfill design and operations for over 12 years. Her expertise includes backfill management planning, hydraulic modelling of distribution systems and start-up/ commissioning of backfill operations. • • • • • Material testing and recipe selection Process design Equipment selection Plant layouts Plant performance optimisation 12:00 Lunch 13:00 Underground reticulation and placement Dr Angus Paterson, Paterson & Cooke, South Africa Dr Angus Paterson Managing Director Paterson & Cooke, South Africa Dr Dave Stone President Minefill Services, Inc., USA • Material testing and slurry flow modelling • Hydraulic design • Piping materials and layout • Flushing, blockages and cleaning 14:40 Afternoon break David‘s proficiency in mine backfill extends the full spectrum from hydraulic fill and cemented rockfill to more recent technologies in paste fill and thickened tailings. His experience includes the geomechanical design of cemented fill for underground placement as well as the design and costing of backfill preparation plants for paste fill and rockfill. Steve Wilson Director & Mining Engineer Paterson & Cooke, UK 15:00 Operations Maureen McGuinness, Paterson & Cooke, Canada • Operational structure • Quality control and monitoring • Continuous improvement and reliability • Cost reduction 16:40 Discussion 17:00 Course close Steve has worked on a wide range of international paste and mining related projects. His experience with paste and thickened tailings technology has been applied to a range of mining applications, both for surface disposal and underground backfill, and its application in industries other than mining. No course proceedings will be available for purchase. *This programme was correct at time of printing. For updates, please visit www.paste2015.com/events. W W W. PA S T E 2 0 1 5 . CO M CONTACT DETAILS IMPORTANT NOTE Please print. *denotes mandatory fields. *Title (Mr, Mrs, Miss, Ms, Dr, Prof., Other) ________________________________ *Family Name_______________________________________________________ *First Name_________________________________________________________ Paste 2015 Seminar speakers please do not fill out this form. Speakers must fill out the speaker registration form provided at time of paper acceptance. The speaker registration fee for the Paste 2015 Seminar is AUD 1,100. † Please visit www.acg.uwa.edu.au/corp_affiliates to view the list of ACG Corporate Affiliates. ^ Students are required to provide proof of full-time enrolment. Preferred Name______________________________________________________ *Position___________________________________________________________ Rheology Fundamentals for Slurries and Pastes Short Course (1505a) | 3 May 2015 *Organisation_______________________________________________________ *Mine/Dept_________________________________________________________ *Address___________________________________________________________ __________________________________________________________________ Earlybird Paid until 23 Mar 2015 Standard Paid after 23 Mar 2015 Standard 770 990 ACG Affiliate† 550 770 Student^ 110 330 Phone_____________________________________________________________ Fax________________________________________________________________ An Introduction to the Design of High Density Tailings Disposal Pipelines Short Course (1505b) | 4 May 2015 Mobile_____________________________________________________________ *Email_____________________________________________________________ All full registrations will have their name, affiliation, address, telephone, fax and email address printed in the delegate list and will receive event proceedings, luncheons and refreshments. Do not include my details in the event delegate list If you require an invitation letter for Visa purposes, please forward a copy of your passport information page. For more information regarding Australian Visas, please visit http://www.immi.gov.au/visitors/_pdf/general-events.pdf Earlybird Paid until 23 Mar 2015 Standard 770 990 ACG Affiliate† 550 770 Student^ 110 330 Mine Backfill System Design, Operation and Management Short Course (1503) | 4 May 2015 Earlybird Paid until 23 Mar 2015 PAYMENT DETAILS Payment to accompany registration – Credit card or EFT. Please contact the ACG for bank details. All prices include GST. ABN 37 882 817 280 Total payment AUD __________________ Standard Paid after 23 Mar 2015 Standard Paid after 23 Mar 2015 Standard 770 990 ACG Affiliate† 550 770 Student^ 110 330 Please note that these courses run on the same date. R E G I S T R AT I O N F O R M PASTE 2015 5–7 May 2015 Pullman Cairns International Hotel Queensland | Australia Credit Card Visa Paste 2015 Seminar (1504) | 5–7 May 2015 Mastercard Earlybird Paid until 23 Mar 2015 Card Number Expiry Date: _____ / _____ Name of Cardholder_______________________________________ Signature________________________________________________ Receipt addressed to Cardholder Business Up to 8 days before event commencement: an administration fee of AUD 150 will be charged. 7 or less days before: no refund. Non-attendance: no refund. Substitutions will be accepted at any time. The ACG reserves the right to cancel the seminar and associated events if insufficient registrations are received. ACG, PO Box 3296 – Broadway Nedlands, Western Australia AUSTRALIA 6009 Standard 1,760 1,980 ACG Affiliate† 1,540 1,760 Student^ 330 550 Paste 2015 Seminar Dinner 6 May 2015 132 Please notify us below of any special dietary requirements. DELEGATE CANCELLATIONS How to register: Standard Paid after 23 Mar 2015 +61 8 6488 3300 __________________________________________________________ Follow us +61 8 6488 1130 [email protected] www.paste2015.com

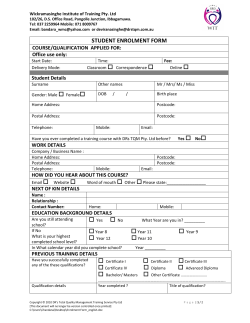

© Copyright 2026