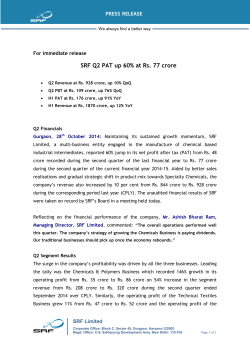

Report No. 01 - DEMANDS FOR GRANTS (2014-15)