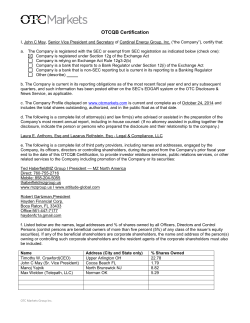

Wednesday Edition