- Applied Mathematics in engineering, management and

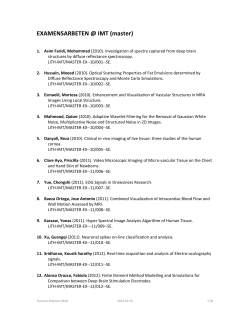

Applied mathematics in Engineering, Management and Technology 2 (3) 2014:24-32 www.amiemt-journal.com Vehicle Interior Acoustic Optimization by Using Passive Layers Gharehbaghi M.a, Iray Makvandi R.a Process Development and Equipment Technology Division Research Institute of Petroleum Industry Tehran, Iran Abstract There is a daily demand increase for ride comfort in car manufacturing industries. The development of lighter and more fuel-efficient automobiles, make vehicles susceptible to low frequency vibration and noise, so uncomfortably is now a new concern in modern products. A pre-production NVH analysis is the key for achieving a proper ride comfort. In this paper, first the effect of structural vibration on the internal noise level of vehicle namely structure-borne noise is investigated. The range of investigated frequency is between 0-250Hz. Acoustical FE simulation is performed on a three internal space cavity of a truck. The analysis was carried out in frequency response analysis and resultant internal noise level is determined. The results of the above analysis are used for optimizing driver's right ear noise level through location and thickness of damping layers. This method is categorized as a passive noise reduction method and is the most economical way for reducing the noise level for the mid range vehicles. To achieve this goal, number of simulations is designed using Taguchi’s method in design of experiments (T-DOE). Then develop a general interpolation function on the sample points using artificial neural network (ANN) method. And finally determine the optimum state by means of a genetic algorithm (GA). Using this method the optimization of parameters (SPL and Weight of Passive Layers) was attained effectively. The results indicate that by proper use of these layers, one can make a reduction of 10-15dB in sound pressure level. Key words: Acoustic, Interior Noise, Passive Layer, Taguchi’s method. 1.INTRODUCTION The development of lighter and more fuel-efficient automobiles, make vehicles susceptible to low frequency vibration and noise, so uncomfortably is now a new concern in modern products. In the past several years, there has been an increased marketplace awareness of noise, vibration, and harshness performance in automobiles. The differentiation between the quality and reliability levels of automobiles has become less pronounced and, as a result, manufacturers have had to demonstrate superiority by focusing on NVH concerns. The current battle began in 1989 when Toyota introduced its Lexus luxury line [1]. The Lexus incorporated groundbreaking techniques for NVH improvements that resulted in vehicles that were substantially quieter than any other car on the market. Lexus had set a new standard for quality and increased customer expectations for both noise and vibration comfort. The automotive industry is currently spending millions of dollars on NVH works. The new design methods are starting to consider NVH issues throughout the whole design process, not just in the later stages. This involves integrating extensive modeling, simulation, evaluation, and optimization techniques into the design process to insure both noise and vibration comfort. In this way, the use of Computer Aided Engineering (CAE) tools is essential for reducing project time and enhancing product quality. Vibro-Acoustic modeling using finite element methods [2] helps the engineers to improve the acoustic comfort by predicting the acoustic response in early stages of design and by means of passive and active ways of noise control. In this paper, optimizing the sound pressure level by means of absorbing layers as one of the efficient and economical ways has been investigated. This method is categorized as a passive noise reduction method. Passive methods in low frequency ranges are not so effective and of course need thick sections to work well enough. Having limitations in thickness of these layers in different cabin locations and limited total weight, besides having an acceptable noise level lead to a complicated optimizing problem that is the reason of utilizing artificial neural network (ANN) and genetic algorithm (GA) for optimizing in this paper. 24 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi Usually structure-borne noise in automobiles is predominant in frequencies below 250Hz [3], so the paper’s interest range of frequency is 0Hz to 250Hz (low-frequency range) and particularly that noise which is generated by the structural vibration of the cabin’s walls and mounts. The organization of the paper is as follows. Section 2 shows the cavity acoustic modes and interior acoustic prediction due to structural excitations or in other words, structure-borne noise analysis. Creating data using taghuchi method is presented in Section 3. Section 4 describes the procedures to optimize the problem. The paper ends with some concluding remarks in Section 5. 2.ACUSTIC CAVITY MODEL The finite element model has been developed in two stages. First, the acoustic behavior of the cavity was studied; second, the model was excited by harmonic loads. 2.1.Finite Element Model The acoustic dynamics of the cavity are fully described by three parameters: the natural frequencies, the mode shape and damping associated with each natural frequency. Note however, that analytically obtaining the damping associated with each mode is not straightforward and usually extracted experimentally [4]. The dimensions and shape of the cavity as well as the characteristics of the fluid (Air at 25 C, in this case) are determined. The model contains 17472 acoustic elements, with the average size of 25 mm, considering more than 8-10 elements that are needed per wave length for accurate representation of the dynamics [5]. Figure 1: interior acoustic cavity model 2.2.Modal Analysis The pressure distribution was studied by acoustic modal analysis. Convergence study on the number of elements has been performed, too. Natural frequencies are tabulated (table 1). 25 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi Table 1: cavity natural frequencies Mode no. Frequency (Hz) 1 98.367 2 131.91 3 162.47 4 173.37 5 196.66 6 213.34 7 230.36 8 247.97 9 253.31 Mode shapes provide information concerning strategy of locations in which the interior noise can be controlled [4]. The place that is anti node or the pressure amplitude is maximum should be treated in order to reduce noise. Acoustic cavity modal analysis provides valuable data’s in predicting the acoustic behavior and should perform in vibro-acoustic analysis. 2.3.Sound Pressure Calculation To calculate the sound pressure level (SPL) the model was excited by harmonic loads and then the sound pressure level at driver’s right ear was calculated for such excitations. The cabin has four connection points with the chassis: two in the front and two under the seat. These points are thought to be the main source of cabin excitations and so the interior noise in the car. The sound pressure level calculated using acoustic pressure, at driver’s right ear (DRE). First of all, an investigation on linearity of the model has been performed. The model excited and the pressure (pa) calculated, then the excitation increased 10 times and again the pressure calculated. The results are shown in figure 2. Changing ten times in pressure from one case to another, demonstrated that the model works well and can be used for further analysis. 26 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi Figure 2: Investigation of model’s linearity (pressure magnitude (pa)) The sound pressure level at DRE (driver’s right ear) is calculated for excitations cabin’s mounts. One of the results is shown below. Figure 3: Pressure (pa) and SPL (dB) for firewall excitation, at DRE Sound pressure level for two cases: with and without sound absorbing materials can be simulated and calculated. The method as mentioned before is Finite Element method. 3.CREATING DATA USING TAGUCHI METHOD Basically, design of the system parameters for engineering proposes is a complex challenge which needs experience, especially for the processes with large number of parameters. The first step to design is to be acquainted with the response of the cavity to any parameter. Usually the second step is to gathering data on the whole design space i.e. the domain where all parameters can change. However, gathering data is a big challenge, which requires design of experiments (DOE). In recent years the Taguchi method has become a powerful tool for engineering proposes especially those with expensive experiments [6]. The Taguchi method uses a special design of orthogonal arrays to study the entire design space with a small number of experiments. Taguchi method simplified design of experiments using some orthogonal arrays as standard arrays. Proper choosing of an orthogonal array which satisfies the problem conditions is the only job an experiment designer should fulfill. 3.1.Execute the Taguchi's Method In the present study, ten parameters containing location, area and thichness of damping layers, are considered. According to the chosen Tagochi's array (L'36) variety domain of any parameter is divided to 3 and 2 levels [7]. The values of the parameters in any level are listed in Table 2. Domain of any parameter is estimated according to the values that are applicable due to a real physical condition. 27 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi Table 2: System parameters and their levels Location Level Factor Doors 3 2 1 Area (m2) 0.30 0.15 0.00 Thickness (in) - 1.0 1/2 Area (m ) 0.90 0.60 0.30 Thickness (in) - 1.0 1/2 Area (m2) 1.05 0.70 0.35 Thickness (in) - 1/4 0.0 Area (m ) 1.20 0.80 0.40 Thickness (in) - 1/2 1/4 Area (m2) 1.20 0.80 0.40 Thickness (in) - 1/4 0.0 2 Firewall Roof 2 Chairs Floor Neglecting combined effect between parameters, 15 degrees of freedom owing to the ten sets of two and three level system parameters is calculated [7]. The degrees of freedom for the orthogonal array should be greater than or at least equal to those for the process parameters. In this study, an L'36 orthogonal array was used. The weight of layers and the under diagram area of SPL-Fr for any array is presented on appendix Table 3 where thirty six experiments are required to study the entire system parameter space. Table3: Data from Taguchi L'36 for training and test of networks layer area (m2) layer thichness (in) ID roof chair floor under diagra area weight (kg) 1 firewa roof chair floor door firewall ll 0.5 0.5 0 0.25 0 0 0.3 0.35 0.4 0.4 12050 0.61 2 0.5 0.5 0 0.25 0 0.15 0.6 0.7 0.8 0.8 11780 1.4 3 0.5 0.5 0 0.25 0 0.3 0.9 1.05 1.2 1.2 11350 2.19 4 0.5 0.5 0 0.25 0 0 0.3 0.35 0.4 0.8 12050 0.61 5 0.5 0.5 0 0.25 0 0.15 0.6 0.7 0.8 1.2 11780 1.4 6 0.5 0.5 0 0.25 0 0.3 0.9 1.05 1.2 0.4 11350 2.19 7 0.5 0.5 0.25 0.5 0.25 0 0.3 0.7 1.2 0.4 11050 2.49 8 0.5 0.5 0.25 0.5 0.25 0.15 0.6 1.05 0.4 0.8 10900 2.52 0.5 0.25 0.5 0.25 door 9 0.5 0.3 0.9 0.35 0.8 1.2 10800 3.37 10 0.5 1 0 0.5 0.25 0 0.3 1.05 0.8 0.4 11700 1.94 11 0.5 1 0 0.5 0.25 0.15 0.6 0.35 1.2 0.8 10850 3.58 12 0.5 1 0 0.5 0.25 0.3 0.9 0.7 0.4 1.2 10700 3.76 13 0.5 1 0.25 0.25 0.25 0 0.6 1.05 0.4 1.2 10690 3.07 14 0.5 1 0.25 0.25 0.25 0.15 0.9 0.35 0.8 0.4 10730 3.31 15 0.5 1 0.25 0.25 0.25 0.3 0.3 0.7 1.2 0.8 11020 2.73 16 0.5 1 0.25 0.5 0 0 0.6 1.05 0.8 0.4 10720 3.07 17 0.5 1 0.25 0.5 0 0.15 0.9 0.35 1.2 0.8 11000 4.04 18 0.5 1 0.25 0.5 0 0.3 0.3 0.7 0.4 1.2 11550 2 28 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi 19 1 0.5 0.25 0.5 0 0 0.6 0.35 1.2 1.2 11110 2.4 20 1 0.5 0.25 0.5 0 0.15 21 1 0.5 0.25 0.5 0 0.3 0.9 0.7 0.4 0.4 10950 2.37 0.3 1.05 0.8 0.8 11500 2.7 22 1 0.5 0.25 0.25 0.25 0 0.6 0.7 1.2 1.2 11140 2.61 23 1 24 1 0.5 0.25 0.25 0.25 0.15 0.9 1.05 0.4 0.4 10820 2.58 0.5 0.25 0.25 0.25 0.3 0.3 0.35 0.8 0.8 11270 2.28 25 1 0.5 0 0.5 0.25 0 0.9 0.7 0.4 0.8 10900 2.06 26 1 0.5 27 1 0.5 0 0.5 0.25 0.15 0.3 1.05 0.8 1.2 11210 2.43 0 0.5 0.25 0.3 0.6 0.35 1.2 0.4 11100 3.16 28 1 1 0.25 0.25 0 0 0.9 0.7 0.8 0.8 11120 3.1 29 1 1 30 1 1 0.25 0.25 0 0.15 0.3 1.05 1.2 1.2 11010 2.46 0.25 0.25 0 0.3 0.6 0.35 0.4 0.4 11000 2.64 31 1 1 0 0.5 0 0 0.9 1.05 1.2 0.8 11230 3.64 32 1 1 33 1 1 0 0.5 0 0.15 0.3 0.35 0.4 1.2 11450 1.58 0 0.5 0 0.3 0.6 0.7 0.8 0.4 11030 3.16 34 1 35 1 1 0 0.25 0.25 0 0.9 0.35 0.8 1.2 10800 3.4 1 0 0.25 0.25 0.15 0.3 0.7 1.2 0.4 11230 2.06 36 1 1 0 0.25 0.25 0.3 0.6 1.05 0.4 0.8 10930 2.91 4.OPTIMIZATION PROCESS The systematic simulations by use of DOE will provide proper results to obtain a true function and optimize it by considering all problem limitations. This can be achieved by use of Artificial Neural Network and Genetic Algorithm, described as followed. 4.1.Modeling Using Neural Network The main task of the neural network is to prepare the optimization goal function. For optimizing, a goal function is required. This function is a mathematical function defined by the neural network. 4.1.1.Artificial Neural Network for Predicting the Goal Function Neural networks have seen an explosion of interest over the last few years, and are being successfully applied across an extraordinary range of problem domains, in areas as diverse as finance, medicine, engineering, geology and physics. Indeed, anywhere that there are problems of prediction, classification or control, neural networks are being introduced. A neural network is an adaptable system that can learn relationships through repeated presentation of data and is capable of generalizing to new, previously unseen data. If a network is to be of any use, there must be inputs (which carry the values of variables of interest in the outside world) and outputs (which form predictions, or control signals). Inputs and outputs correspond to sensory and motor nerves such as those coming from the eyes and leading to the hands. However, there may also be hidden neurones, which play an internal role in the network. The input, hidden and output neurones need to be connected together. To capture the essence of biological neural systems, an artificial neurone is used. It receives a number of inputs (either from original data, or from the output of other neurones in the neural network). Each input comes via a connection, which has a strength (or weight); these weights correspond to synaptic efficacy in a biological neurone. Each neurone also has a single threshold value. The weighted sum of the inputs is formed, and the threshold subtracted, to compose the activation of the neurone (also known as the post-synaptic potential, or PSP, of the neurone). The activation signal is passed through an activation function (also known as a transfer function) to produce the output of the neurone. For our application, this function is a sigmoid function, which is the same for all neurones. The best-known example of a neural network training algorithm is error back-propagation. The modified Levenberg–Marquardt approximation algorithm 29 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi is employed to further enhance the overall accuracy of the network and to avoid overfitting. The adjustment of weights and biases are done according to the following transfer function: DW = (J T J + m I ) -1 J T e (1) Where J is Jacobian matrix of derivation of each error m is a scalar and e is error function. The training process continues until either the error goal is met, the maximum number of epochs is completed, or m reaches a maximum value. The variable m determines whether learning processes is according to Newton’s method or by gradient descent. 26 of the L'36 array data in table 3 are used for network training and 10 used for test network data. The number of neurons in the hidden layer is determined by trial-and-error experimentation. The performance of the neural network depends on the number of hidden layers and the number of neurones in the hidden layers. Therefore, many attempts should be carried out in choosing the optimal structure for the neural network by changing the number of hidden layers as well as the number of neurones in each of these hidden layers. In this study, the structure of the neural network is 10–8–5–1 (10 neurones in the input layer, 8 in the 1st hidden layer, and 5 in the 2nd hidden layer and 1 in the output layer). Tangent-sigmoid transfer function was employed for the hidden layers and linear transfer function for the output layer. A mean network error of 0.08% and 1.32% for network training and testing data was achieved respectively. Effect of two system parameters; thickness of layers and areas of them are presented in following figures. The effect of each parameter is investigated while others are fixed. As shown in figure 4, the most effective place to use absorbing layers is floor where the vibrations, so the source of noise, is generated form it. Firewall and chair have the next level of proper sound absorbing places, respectively. Figure 4: thickness effect on under diagram area (noise intensity) Another parameter is the area of absorbing layers. The effect of this parameter can be studied by means of artificial neural network (figure 5). Note that the thicknesses and areas in these two figures are normal (-1 stands for zero value and 1 represent the maximum value of the parameters). Figure 5: area effect on under diagram area (noise intensity) 30 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi 4.2.Genetic Algorithm Genetic algorithms (GAs) are well known types of evolutionary computation methods today and have been adapted for a large number of applications in different areas [8]. Genetic Algorithms, first proposed by John Holland in 1975 [9]. These methods have their philosophical basis in Darwin's theory of survival of the best and belong to a general category of stochastic search methods. These algorithms encode a potential solution to a specific problem on simple chromosome string like data structure and apply specified operators to these structures so as to preserve critical information, and to produce a new set of population with the purpose of generating strings which map to high function values. 4.2.1.Applying genetic algorithm to the problem In the final optimization problem the under diagram area (represent as noise level) was defined as the goal function which should be minimized. The program final output values are shown in Table 4. Table 4: Optimum parameters parameter Opt. value Area (m2) 0.3 Doors Thickness (in) 0.5 Area (m2) 0.9 Firewall Thickness (in) 0.9 Area (m2) 0.6 Roof Thickness (in) 0.2 Area (m2) 0.6 Chairs Thickness (in) 0.3 Area (m2) 1.2 Floor Thickness (in) 0.2 Using the outputs of optimization problem as the inputs of the FE simulation, the optimum SPL diagram for such parameters can be achieved. Figure 6 shows response of the optimal system. Figure 6: system’s acoustic response in optimal point The calculated under diagram area from this figure, is 10705 (dB-Hz), which is comparable with that predicted by the ANN. Good agreement observed between results estimated by the ANN for many other input data from all around the design space were compared with values determined directly by simulations which it is debt to orthogonal input data performed by Tagochi's method. 5.CONCLUSIONS 31 Applied mathematics in Engineering, Management and Technology 2 (3) 2014 M. Gharehbaghi and R. Iray Makvandi The reduction in noise level by means of passive layers is one of the effective methods in spite of simplicity and low cost. The limited frequency where this method can apply and increasing in total weight are the major deficiencies of this method. REFERENCES [1] Maa Dah-you and Li Pei-zi, “Pressure Dependence of Jet Noise and Silencing of Blow-offs,” Noise Control Engineering Journal, 17, 104–112 (1981). [2] F. Holste and W. Neise, “Experimental comparison of standardized sound power measurement procedures for fans,” Journal of Sound and Vibration, 152, 1-26 (1992). [3] T. F. W. Embleton, “Experimental study of noise reduction in centrifugal blowers,” Journal of the Acoustical Society of America, 35(5), 700-705 (1963). [4] Leo L. Beranek, “Criteria for noise and vibration in communities, buildings, and vehicles,” Chap. 17 in Noise and Vibration Control Engineering-Principles and Applications, edited by Leo L. Beranek and Istvan L. Ver (Wiley, New York, 1992). [5] Bernard Widrow and Samuel D. Stearns, Adaptive Signal Processing (Prentice-Hall, Englewood Cliffs, New Jersey, 1985). [6] D. A. Kienholz and K. E. Smith, “Admittance Modeling: Frequency Domain, Physical Coordinate Methods for Multi-Component Systems,” Proceedings of the 6th International Modal Analysis Congress (1988), pp. 608-614. [7] Volker Nitsche, “Application of aircraft noise monitoring systems at German airports,” Proceedings of INTER-NOISE 95, edited by Robert J. Bernhard and J. Stuart Bolton, Vol. 2, pp. 755-758, 1995. [8] U. Sandberg and J.A. Ejsmont, “The influence of tire age and wear on tire/road noise emission,” Proceedings of INTER-NOISE 02, edited by Ahmet Selamet, Rajendra Singh, and George C. Maling, paper in02_454, 2002. [9] Acoustics-Description and Measurement of Environmental Noise-Part 2: Acquisition of Data Pertinent to Land Use, International Standard ISO 1996-2: 1990 (International Organization for Standardization, Geneva, Switzerland, 1990). [10] Sound Level Meters, International Standard IEC 651:1979 (International Electrotechnical Commission, Geneva, Switzerland, 1979). [11] American National Standard Acoustical Terminology, American National Standards Institute ANSI S1.1-1994 (Acoustical Society of America, New York, 1994). 32

© Copyright 2026