An observation of combustion behavior of a single coal

Combustion and Flame xxx (2015) xxx–xxx Contents lists available at ScienceDirect Combustion and Flame j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / c o m b u s t fl a m e An observation of combustion behavior of a single coal particle entrained into hot gas flow Hookyung Lee 1, Sangmin Choi ⇑ Department of Mechanical Engineering, Korea Advanced Institute of Science and Technology (KAIST), 291 Daehak-ro, Yuseong-gu, Daejeon 305-701, Republic of Korea a r t i c l e i n f o Article history: Received 17 December 2014 Received in revised form 12 March 2015 Accepted 13 March 2015 Available online xxxx Keywords: Coal Single particle combustion Cross-jet arrangement Quantitative observation a b s t r a c t This experimental investigation undertakes visual observation of burning coal particles in a hot flowing gas environment, focusing on the initial stages of coal combustion. Pulverized single coal particles transported by cold carrier gas are injected perpendicularly into a high-temperature environment up to 1240 K and 16.7-40.2 % of O2. High-speed photography with microscopic magnification in half-shadow conditions provided improved images of the combustion behavior of moving particles and flames in time and space. Spatial location of the particle along with a known time interval allowed positioning as related with the mixing gas flows. This approach allowed the timing of the characteristic sequence of the subprocesses. Observed images of burning particles were quantified in terms of changing size, shape, and intensity of the apparent flame emission. This method enabled an interpretation regarding the progress of volatile flame formation observed by the visual appearance of the particle and its associated flame. The size measurement of the apparent volatile flames with varying particle size and oxygen concentration also allowed instructive discussions along with model descriptions of spherically concentric formation of the volatile flames. The observation results of the burning particles starting from the injection, heat-up, formation of volatile flames as well as the progression of the heterogeneous reaction are presented. Ó 2015 The Combustion Institute. Published by Elsevier Inc. All rights reserved. 1. Introduction The phenomenological understanding of combustion processes of a single coal particle has formed the basis of the mathematical description of coal particle combustion models, which include mixing and transport of particles in the gas flow, heat transfer to and from the particle, volatile release from the particle typically as a function of temperature, oxidation of released volatiles, and char oxidation. This modeling description of a single pulverized coal particle, the typical size of which ranges on the order of a few tens to hundreds of a micrometer in diameter, has been incorporated into a comprehensive computational model [1], which is further extended to now-commonly used programs as an associated package of computational fluid dynamics (CFD) codes. Description of combustion processes of a single coal particle has likely benefited from the more extensively studied topic of single liquid fuel droplet combustion. A simplified geometry of the ⇑ Corresponding author. Tel.: +82 42-350-3030; fax: +82 42-350-1284. 1 E-mail addresses: [email protected] (H. Lee), [email protected] (S. Choi). Tel.: +82 42 350 3070; fax: +82 42 350 1284. spherical symmetry, the heat-up of a single droplet or particle in a high-temperature gas environment, the evaporation or release of volatile fuel, and the formation of a homogenous spherical flame are typically analogous [2,3]. Heat-up and the release of volatiles by devolatilization in the early stages are often discussed with analogical reference [4–7], such as a concentric flame sheet concept with the liquid fuel droplets. Describing the combustion processes of a single coal particle is not simple because of its heterogeneous characteristics [8]. Overcoming the complexities of the inhomogeneous nature of shape, composition, and reactive properties, extensive research on devolatilization [9–11] and char combustion [12,13] has contributed to the formation of the modeling concept of coal combustion. The combustion of a pulverized coal particle is typically associated with a series of sequential processes along with the physical and chemical deformation of solid particles and the gassolid phase reaction [14]. The model concept associated with combustion behavior can be postulated based on visual observation. Characteristic regions in the overall combustion process can be identified based on the visual appearance of the particle and its associated flame, including the dynamic formation and extinction of the volatile flame and char oxidation. http://dx.doi.org/10.1016/j.combustflame.2015.03.010 0010-2180/Ó 2015 The Combustion Institute. Published by Elsevier Inc. All rights reserved. Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 2 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx The apparent flame behavior of coal particles is closely related with the hydrodynamic interaction of the solid and gas phases in addition to the combustion-related properties of fuel coal. Coal particles transported by a carrier gas are generally injected from burners into a non-quiescent environment of the hot flow field in conventional applications. In this case, the physical and thermal mixing of the flow fields is regarded as one of the important variables in determining the combustion status of the particle entrained into hot gas flow. Direct observation of pulverized coal particles in a high-temperature gas environment has provided insight for phenomenological understanding. Experimental investigation through observation of the apparent characteristics over the combustion processes of single coal particles in a hot gas environment has been documented over the years [15–20]. The heat-up and devolatilization processes are indelibly associated with the ignition characteristics of the volatile matter released from coal particles because the heat-up region is generally recognized as a previous stage of homogeneous ignition. McLean et al. [15] observed particles entrained into a high-temperature gas environment ranging from 0-20 % O2 and 1100-1800 K in temperature in a co-flow injection arrangement between coal particle jets and post-combustion gas. Devolatilizing coal particles were identified through bright yellow emissions where the initial bright zone is thicker and more diffuse than the following region. The location of the bright emission onset was referred as the ignition point. The condensed phase released from the coal particles was elongated, forming tails upwards because of velocity slip and a faster burn rate at 20 % O2 compared to 8 % O2 concentration at 1700 K. In a similar experimental approach, devolatilization and ignition behavior were measured in the middle of the upward trajectory of the single coal particle through some observation schemes [16,17]. Molina and Shaddix [16] defined the coal ignition point as the onset of the CH⁄ chemiluminescence signal instead of the appearance of the visible flame. CH⁄ emission released from the coal particles was observed and compared with blackbody emission in the 21 and 30 % O2 and at approximately 1200 K in both the N2 and CO2 environments. To improve limited sensitivity to the differences in particle ignition and devolatilization in Ref. [16], Shaddix and Molina [17] employed an intensified charge-coupled device (ICCD) to image the individual particles. Ignition was characterized by the formation of a soot cloud surrounding the particle. The soot cloud around the devolatilizing particles was observed through the particle imaging of two coal types at a gas temperature of 1700 K over a range of 12-36 % O2 in both N2 and CO2 diluent gases. As the O2 concentration increased, the soot cloud shrunk in size and formed more concentrically about the coal particle. In Refs. [18–20], the particle free-falling condition was considered in hot quiescent and active atmospheres of a drop-tube furnace electrically heated to a wall temperature of 1400 K. The results clearly showed the apparent characteristics of the sequential combustion processes of the coal particles. The particles fell down, forming co-tails in the sooty wake of the particle trajectories. Volatile matter ignited forming diffusion flames of a ring shape or of a heterogeneous behavior based on the apparent observation of the different coal types and the biomass fuel in the ranges of 20-100 % O2 in both the N2 and CO2 environments. Experimental investigations have continuously attempted to describe the transient burning behavior of coal particles, especially in simulating the combustion environment and also in providing quantitative results in terms of time and space information. This research investigated the early stages of the combustion processes of a single coal particle entrained into a hot gas flow field. Single coal particles transported by the cold carrier gas and injected perpendicularly into a cross-stream of hot gas flow are observed in a lab-scale entrained flow reactor. The objective of injection method is to precisely define the starting points of particle heat-up and the subsequent processes leading to the char reaction in addition to the associated time and space scales. This will help explain the entrainment behavior of coal particles and their associated flames in the flow. The heat-up phase, the volatiles release and oxidation phase, the flame formation sequence, and the char reaction phase are distinctly revealed while the particles adjust to the main cross-stream. The successive sequence of combustion processes from the injection of the particles is represented, and each region of the processes is quantitatively characterized in terms of the size and intensity based on the observation of formation until extinction of the visible apparent flame. Because the reaction characteristics that affect flame formation surrounding the particles depends on the coal type, the particle size, and the oxygen concentration of flow field, the effects on the sequential regime are discussed. The methodical characteristics on the apparent images further enabled discussions on the mathematical description associated with the combustion behavior of a single coal particle entrained into a hot gas flow. 2. Experimental Details and Procedure 2.1. Cross-jet injection of a single coal particle into a high-temperature gas environment Experiments were conducted in a post-combustion gas flow reactor with a coal particle injector arranged in a cross-flow configuration. Fig. 1 shows the facility, which provides optical access to the early stages of combustion when a single coal particle is entrained into a hot gas environment. A 40 40 mm square quartz tube with thickness of 5 mm isolates the reacting particles and combustion product gas from the surrounding atmosphere; it allows optical access into the test section. The reactor operates at atmospheric pressure and uses a stabilized flat flame to provide a high temperature post-combustion gas. Burning a premixed gas mix of commercial propane, air, and extra O2 at a burner produces the combustion gas. The flow rates of each gas are independently adjusted in limited ranges producing the stable flat flame, for which temperature and O2 concentration of the product are controlled. The hot product gas passes through a porous flow straightener made of ceramic honeycomb to make a uniform flow environment in the test section. In this experimental approach, Fig. 1. Schematic of the test section. Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 3 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx confirmation of the uniform flow field of the hot gas was visually verified by introducing the solid coal particles, themselves, into the hot gas flow, as shown in Fig. 1. When introduced into the high-temperature gas flow with a carrier gas, the coal particles passed through the hot flow field in a vertically straight line and show a direct particle image velocimetry (PIV)-like effect. Heating elements and insulation were used to cover the tube to minimize heat loss to atmosphere. This guard heating system enabled a steady hot gas flow while minimizing the temperature drop of the gas flow stream. Additional guard heater covers were installed in the downstream section after the optical window whose height is adjustable. The monitoring system controlled the target gas temperature near the heating elements up to 1023 K. Coal particles were perpendicularly injected through a 2 mm (i.d.) stainless-steel tube at the side of the quartz tube with air as a carrier gas into the hot gaseous environment. The jet tube was placed 10 mm inside the sidewall of the quartz tube to minimize interference with the boundary layer of the gas flow and the quartz tube wall [21]. The coal particles drop down very slowly into a glass funnel by a micro-syringe injector and then are entrained with a carrier gas at room temperature. The flow rate of the carrier gas was independently controlled, regardless of the number of coal particles falling into the glass funnel. This design allows the number density of particles and the jet flow rate to be varied independently. The particle feeding rate was regularly kept to 25-30 particles/min (<0.01 g/min in the mass flow rate) to observe the behavior of nearly each single coal particle to guarantee that the gas condition was not affected by particle combustion. 2.2. Combustion environment Composition of flue gas produced from the combustion of C3H8, air and the extra O2 was typically O2 (16.7-40.2 %), N2 (51.7-75.2 %), CO2 (3.5 %), and H2O (4.6 %). In this study, the extra oxygen was enriched as a variable to make an intense oxygen diffusion environment where it is possible to observe the particle combustion up to the char reaction within the limited field of view in the current scope. The environment of the different oxygen concentration at a nearly constant temperature distribution was achieved by controlling the air and extra oxygen flow rates in a fixed total flow rate, which is 20 standard liters per minute (slpm) for each condition. The temperature of the hot gas flow measured at the inlet of the test section drops by 2.0 K as the oxygen fraction increases by 5.0-5.5 % in the lean post-combustion gas condition. Minor differences in flow temperature exist for the different gas composition, but it is not significant enough to affect the phenomenological trends. The flow rates were determined considering the stability of the flat flame and the gas temperature associated with the flammability of the coal particles. The linear velocity of the carrier gas at the exit of the nozzle of the coal injector and the main gas stream was in the range of 1.3-2.7 m/s and 1 m/s, respectively. Coal particle velocity depends on the particle size, which is related to the initial particle inertia and the intermediate reduction in the particle mass on the rate of volatile release during combustion. The information can be directly obtained with the displacement per unit time of the moving particles based on the interval between the frames. The temperature profile of the gas flow was measured at the points on the centerline, vertically at a 5 mm interval over 40 mm (total measured points: 9) along the reactor height in the test section with a type R thermocouple, for which uncertainty of the measurements and radiative correction were evaluated. Fluctuating temperature data were typically averaged over 30 seconds. Temperature of gas flow introduced into the test section was typically up to 1240 K at the exit (0 mm) of the injection tube, and the gradient was formed along the reactor height, reaching up to 1150 K at the exit (40 mm) of the observation section. However, the field of view where the particle heat-up and subsequent processes until initiation of the char reaction occur is sufficiently narrow (vertically 0-11.0 mm), so the coal combustion stages are mostly revealed inside the mixing region of the cross jet. An initial hot gas flow condition is maintained at approximately 1230-1240 K with little gas temperature variation. The vertical temperature profile along the centerline of the reactor height in this cross-jet injection configuration is noticeably different from the one in the co-jet injection configuration [16,17] because a single coal particle transported by the cross jet is intensely mixed with the main stream of the hot gas flow. One of the focal concern of the current phase of this research is to define the starting point for particle heat-up and the effect of flow mixing on the transient combustion behavior of the particles; therefore, the gas flow environment, especially the stream mixing region in the early stages of combustion, would be characterized. This would help explain the ignition delay reaching a certain temperature for volatile oxidation. Detailed characterization results associated with the experimental environment by a cold cross jet into a hot gas flow will follow in the forthcoming report, where detailed arguments will be presented, associated with the uncertain particle temperature history and the flame temperature in this cross jet mixing configuration. It is assumed that there is no radical species in the hot gas stream and that the volatiles ignition depended only on the thermal conditions around the single particle. In this condition, the particles reach the devolatilization temperature of over 600-700 K and the homogeneous ignition temperature of over 1000 K within 20 ms [22]. However, it is not simple to unambiguously determine a particle-heating rate due to the non-uniform temperature distribution because of the mixing between the cold carrier gas jet and the hot main stream flow until equilibrium is reached. 2.3. Coal type and properties Two types of coal, one of high volatile bituminous and another of subbituminous were used in this experiment. Both coals were sieved to a size range of 75-90, 125-150, and 180-200 lm. Proximate and ultimate analysis data of two coals are summarized in Table 1. During the preliminary tests with coals of varying ranks, while the combustion of the volatiles released from the bituminous coal was sooty and luminous with tails forming in the wake of the particle trajectories, lignite coal experienced extensive fragmentation, immediately followed by ignition of the char fragments spread apart into a relatively large volume. The current paper reports test results with higher rank coals, which can provide useful discussion on the model description of the apparent combustion behavior of coal particles. Table 1 Coal properties. Rank Bituminous F Subbituminous P Proximate (air-dried) (wt%) Ultimate (air-dried) (wt%) Heating value (MJ/kg) W V.M. F.C. Ash C H O N S 2.38 2.47 35.32 28.76 49.62 50.64 12.68 18.13 70.38 64.44 4.65 3.73 7.91 9.10 1.48 1.79 0.52 0.35 Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 27.98 24.82 4 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx 2.4. Observation scheme and uncertainty The purpose of this report is to elucidate the apparent combustion characteristics obtained from visual observation. In this study, the combustion behavior of single coal particles was observed using a high-speed camera (Phantom V310, Vision Research) to investigate the apparent changes on the time and space scales in the short residence time (<40 ms at least) of the particles. The camera has a complementary metal oxide semiconductor (CMOS) sensor size of 25.6 16.0 mm and a pixel size of 20 lm at a 1280 800 resolution for observation through a normal lens. To produce images at higher magnification in this study, however, an adjustable 50 mm photographic bellows and a 200 mm focal length f/32 camera lens with macro function (Nikon) were used to fill the image detector for a 14.6 11.0 mm field of view. In the case of this observation condition, the total depth of field was calculated to nearly 3 mm, and the size of the pixel was measured to 14.3 lm at a 1024 768 resolution. The pixel size was calibrated on a circle and line-scale reticle with calibrated features that fit completely inside the field of view of the video for this magnification, as indicated in Fig. 2. Larger fields of view with lower magnification permit the observation of a larger portion until the end of char reaction process for several particles simultaneously in the space of a single frame. In the current study, a speed of 4200 frames per second (fps) and exposure time of 10 ls per frame were applied to each image with continuous backlighting by a halogen lamp. More than 20 videos were recorded for each particular experimental condition to obtain the averaged results considering the repeatability. Accurate measurement of the length scale is important in sizing the apparent shape changes in detail. Furthermore, the outwards appearance of the pulverized coal particles, which have a size on the order of a few tens to hundreds of a micrometer in diameter, is subject to a certain degree of uncertainty resulting from the mechanical limitations of the observation apparatus. Current recording size of the pixel might not be sufficiently precise in the case of a smaller particle size. Fig. 2 quantitatively presents an observational error of the diameter ranges of the particles considered in this study. It was calculated based on measurement of the number of maximum and minimum pixels where the diameter of the actual particles can occupy the field of view. In the images, it appears more diffuse than the actual size as the diameter of the particle becomes smaller. Because the degree of uncertainty decreases as the size of the objects increase, however, the enveloped volatile flames, which are several times larger than the size of the coal particle, could be measured with confidence based on the current set-up. 2.5. Image processing procedure The images were processed to characterize the flame intensity as well as the size, both for the particle and the flame. Successive images were captured using the high-speed camera, which has gray 8-bit resolution. At each capturing time in the same condition, 20 images were acquired to produce an averaged value to provide quantified results in terms of sizing and receiving intensity. In the case of char oxidation, for example, the surface of the char particle is first partially burned from edge of the non-spherical char surface [23,24], and it was also observed in this study. Therefore, the raw intensity values on the particles in each image have to be averaged to present the characterized intensity values at a point in time. To compare the images under the identical conditions, the gain value and the exposure time of the camera were fixed at all times, as mentioned above. To quantitatively analyze the images, the data, with numbers from zero to 255 corresponding to the intensity at each image pixel, were normalized by the highest value in each of the averaged image to reduce the effects of the contamination on the quartz window or the reflected light from the quartz window. As there was backlighting source, a fixed value was assigned to the pixels, which occupy the background areas, except for the coal particle and volatiles flame in the raw images. The flame region and the particle region could then be distinguished. The summary of the image processing procedure is represented in Fig. 3. The volatile flame area (Af) was calculated by summing the corresponding areas (dApixel) of the pixels in the image data and the effective flame radius (reff) value, which is assumed to be a concentric flame shape, was estimated based on the conservation of the flame area according to the following equation, where rp corresponds to the coal particle radius. reff rffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi Z 1 ¼ Af þ pr 2p ; where Af ¼ dApixel p ð1Þ The mean elongated distance (rc), which is a distance of the intensity-weighted flame center from the particle center, and the mean inclined angle (hc) were estimated from the image data to represent the degree of asymmetric development of volatile flames. It is appropriate to consider the intensity-weighted values of the flame as a threshold because strong and weak values are distributed over the flame regions [25]. The radius of coal particle (rp) normalized the mean elongated distance (rc). They are calculated in the following equations, R R I x dA I y dA x ¼ R ¼ R ; y I dA I dA rc ¼ Fig. 2. Quantified observational error. This shows the trend that the real size value ‘’ follows the minimum measurement value ‘s’ as the particle size increases, and the degree of uncertainty associated with measurement gradually reduces on the display screen as the size of the objects increases. In the range of particle size considered, Max. 33.5 % and Min. 14.0 % (in the case of 75 lm) ? Max. 7.3 % and Min. 0.1 % (in the case of 200 lm). Error values ‘h’ and ‘s’ would reach a zero level for larger size objects. pffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi x2 þ y 2 rp hc ¼ cos1 =r p y rc ð2Þ ð3Þ ð4Þ where x, y, and I correspond to the horizontal coordinate in jet flow direction, the vertical coordinate in hot gas flow direction, and the mean the horizontal and intensity value of flame image.x and y Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx 5 Fig. 3. Representative image processing procedure: (a) raw images, (b) flame image normalized by the highest pixel value, (c) a specific value, 70, is assigned to pixels in the background having the intensity of the back-lighting source. The volatile flame area (Af) and effective flame radius (reff) are assumed to the concentric flame based on the conservation of the number of the pixels are calculated. For example, the values of rc and hc are printed on the bottom of the flame image. vertical coordinates of the intensity-weighted center of the volatile flame region. Large values in rc and hc mean that flame is elongated far from the particle center and that flame is tilted much from the vertical line, respectively. For rc=1, for example, it means that concentric volatile flame is ideally formed around the particle. 3. Results and Discussion 3.1. Sequential regimes of combustion processes of entrained particles Sequential combustion regimes were successively observed from an injection point, t0=0 s and T0=298 K. From the tube tip where particles are injected, heat-up and volatile oxidation processes of single coal particles were clearly identifiable, and subsequent char oxidation phase were visualized as shown in Figs. 4 and 5 (see Fig. S1, video image in the supplementary material, as representative behavior). These images display the initial stages of coal particle combustion on different particle size and O2 concentration in the bulk gas. Because elapsed time from the starting point and displacement of particles till extinction of char reaction (possibly till generation of ash) were relatively long (about 1.0 s and 150 mm, respectively), the visualization till final particle burnout region was limited in this experimental configuration. It is possible to extend the period of observation till the extinction of char reaction in lower magnification. The sequential images provide information associated with the corresponding status of the overall combustion process on the time and spatial location of each particle. It was found that the residence time and displacement of coal particles are variable depending on the particle size and O2 concentration. The size of the particle is a dominant factor in characterizing the physical displacement and apparent combustion behavior of coal particles on time scale. Time window for particle to stay inside the field of view was typically 13-15 ms (75-90 lm), 15-20 ms (125-150 lm), and 25-28 ms (180-200 lm) (see Fig. 4). Images of moving coal particles were superimposed on a single frame. Distance of the particle location between two successive images would correspond to the instantaneous speed of particle multiplied by the time interval. Arranged images show the general trend of the cross-jet mixing configuration. Particle, initially transported by the jet with the momentum only in the horizontal direction, gradually loses horizontal momentum while attains vertical momentum. Entrainment process is typically dependent on the mass of the particle. Smaller particle of 75-90 lm loses almost of horizontal momentum in less than 10 ms, while larger particle of 180-200 lm retains a large amount of horizontal momentum even at 20 ms. Fully entrained particle would follow the mean gas flow, but observed inter-particle distance shows variation, also depending on the particle size; for example 1.1-1.3 mm for 75-90 lm, 0.9-1.1 mm for 125-150 lm, and 1.8-2.0 mm (for 2.4 ms interval) for 180-200 lm. By looking at the images of coal particles, one can notice the shapes of particle are not spherical but of arbitrary natural rock-like form, which is intuitively expected. The particle rotational motion is also observable in addition to the translational motion in the horizontal and vertical direction. Fig. 5 shows the coal particle behavior with respect to oxygen concentration. Now that flow velocity and temperature conditions are nearly identical to those cases shown in Fig. 4, particle motion appears similar. However, shapes of the volatile flames, as well as the time-wise characterization of the volatile flame, are strongly influenced by the oxygen concentration. It is shown that the spherically concentric shape of the volatile flame is visible only for the limited experimental condition, depending on the oxygen concentration and the relative motion of the particles to the mean gas stream. Now that the mass of coal particle is continuously changing on reaction rate during the volatile release and char oxidation, it influences the entrainment behavior. The motion is explained by particle velocity and relaxation time defined as the ratio of the particle aerodynamic response time to the flow Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 6 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx Fig. 4. Sequential images of a single coal particle superimposed on a single frame for better understanding (all particles are introduced at the center of the tube). Three sets of particle trajectories show the effect of particle size (75-90/125-150/180-200 lm) in the ranges of particle size groups on combustion behavior. Bituminous F coal, in O2 34.6 %, 1240 K. Time and displacement intervals are shown on the photo. Fig. 5. Three sets of particles trajectory show the effect of oxygen concentration (21.1/29.8/40.2 %) in the bulk gas environment on combustion behavior. Bituminous F coal with dp 125-150 lm, 1240 K. Time and displacement intervals are shown on the photo. characteristic time. Aerodynamic behavior on changing reactivity by being porous char particles of low density in combustion progress has been reported [26]. The direct observation shots of the particle behavior can be specifically enumerated on time scale in more detail, as presented in Fig. 6. Conceptual stages, which have been typically perceived as particle heat-up, volatile release and combustion, and char oxidation, are schematically depicted. Recorded images of black particles represent shadow images and bright white images of the volatile flames are shown along with the shadow images of the particle in the center. And when the surface emission from the char is visible, shadow image of the particle is not seen. Particles in the heat-up phase are seen as a shadow. The images of volatile flame are believed to originate from the sooty volatile flame, which is Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx 7 Fig. 6. Comparison of the combustion processes for two coal types: Bituminous F coal and Subbituminous P coal, dp 125 lm in O2 34.6 %, 1240 K. Particle heat-up phase (0.72-3.6 ms for F coal and 0.72-5.04 ms for P coal), volatiles release and oxidation phase (4.32-10.08 ms for F coal and 5.76-12.24 ms for P coal), and char reaction phase (10.8 ms onwards for F coal and 12.96 ms onwards for P coal) in this condition. The increasing bar below the photo means the stream of time with 0.72 ms interval between the frames. considered as a volumetric radiative source. In between the extinction of the volatile flame and the char ignition, char particles are seen as a shadow. Burning char particles are typically seen with bright emission. Intensity of char emission varies as char oxidation progresses. Sequential regimes of combustion for the two coal types of different rank are also compared in Fig. 6. Images of bituminous and subbituminous show qualitatively similar progress of the sub-processes of the combustion, where experimental conditions were maintained identical including the characteristic size of the coal particles. Bituminous shows relatively faster progress of combustion compared to subbituminous. Fig. 6 shows one example set of images from the large number of repetitive observation. ignition delay of coal particle flame, the time required from the particle injector tip to the appearance of the visible volatile flame surrounding the particle. Time duration for the apparent volatile flame is defined as the burning time of the volatile flame (svol_oxidation). The particle heat-up time and volatile burning time are summarized in Fig. 7, so that parametric influence of particle size and oxygen concentration on the particle heat-up times is shown. The qualitative universality of particle heat-up and volatile burning times for 75-90 lm particles is consistent with the experimental results by Khatami et al. [19,27] and the theoretical description by Maffei et al. [20]. This is also consistent with the typical mathematical description, a general form mpcp(dTp/dt)=hADT, where particle mass mp, heat capacity cp, particle temperature Tp, heat 3.2. Time scales of particle heat-up, volatile release and char ignition Conceptual representation of the time scales of particle heat-up, volatiles and char combustion is shown in Fig. 6. From the serial images, one can identify the time when the volatile release or oxidation is first observed and the time last observed, as well as, the time when the char combustion is first observed. Although it is difficult to minimize the uncertainty in determining the exact timing because of its continuous changes, time duration for the heat-up and volatile oxidation, and char oxidation can be defined with appearance of visible volatile and char flames. Accordingly, discussion on the time duration for the heat-up, volatile release and oxidation can proceed. Particle temperature increases as a result of convective and radiative heating. The particle heating rate in this experimental condition was calculated to be on the order of 105 K/s, which is corresponding to the typical conditions of pulverized coal flames and previous experimental investigations [9–11,14,22]. Particle heat-up time (sheat-up) is defined as, which has been also called as Fig. 7. Effects of oxygen concentration and particle size (of Bituminous F coal) on particle heat-up time (Ignition delay), sheat-up, and volatile burning time, svol_oxidation. In O2 21.1 and 16.7 %, volatile release was not terminated in this field of view in all particle size groups. In O2 25.4 %, volatile release of 180-200 lm particles was not terminated. Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 8 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx Fig. 8. Effect of oxygen concentration on the effective radius of volatile flame. Bituminous F coal, dp 125 lm. Effective radius of the apparent flame (reff) was obtained through the processing of gray scale images. The heat-up and char reaction regions are indicated through the initiation and ending points of the volatiles oxidation region. In O2 21.1 and 16.7 %, volatile release was not terminated in this time scale. Photo was taken when the flame diameter reaches at its maximum. transfer coefficient h, particle surface area A, and temperature difference DT between the particle and the ambient gas environment [1,14]. As another way of representing the burning time of volatile flames, effective radius of the volatile flame as defined by Eq. (1) is utilized, assuming that the image of the flame is circular (volatile flame is spherical). Validity of this assumption is rather limited in lower oxygen fraction environment, but interpreted result of the time-wise variation of the size of the volatile flame showing the effect of oxygen concentration is informative as shown in Fig. 8. The heat-up region and the initiation points of char oxidation can be found based on the volatile oxidation region identified with the initiation and ending points of reff/rp values on different oxygen concentration. As the oxygen concentration decreases, it took relatively longer until the apparent volatile flame appears on the particle surface. The results are consistent with previous experiments [16,17] that devolatilization proceeds rapidly with higher oxygen vol.%. The oxygen concentration is not generally related to the temperature rise during heat-up of coal particles in the simple mathematical models. However, experimental observations, including those of this study, show the increasing time for appearance of visual volatile flame with decreasing oxygen concentration in the bulk gas. It is also attributed to the longer burning time and the larger effective radius of the volatile flame as the oxygen concentration decreases (see Figs. 5 and 8). As already seen in Fig. 4, size of the volatile flame is related to the size of the coal particle. Fig. 6 shows the difference in dynamic progress of the volatile flames. Fig. 8 also shows the dynamic size variation of the volatile flame along with the effect of oxygen concentration in the mean gas stream. Although particle size and oxygen concentration are shown to affect the dynamic formation of the volatile flame in a plausible manner, quantitative explanation was not attempted. It is natural to expect that formation and shapes of the volatile flame are directly related with the volatiles release rate and the combustion rate of the volatiles, although we have not yet specifically defined the state and contents of the volatiles. As related with formation of the volatile flame for a coal particle, several models [4–7] have been proposed. Basic modeling approach resembles that of the liquid fuel droplet combustion, in which a spherically symmetrical volume of the mantle is filled with the devolatilized products, which will oxidize at a fast rate and form an infinitely thin flame sheet. These mathematical models would require a complete set of information as related with the properties of coal particle and environment conditions. Shape of the volatile flame is not, in general, spherical. As one way of displaying the various shape of the volatile flame, Fig. 9 shows flame images with parametric variation of oxygen mole fraction and the velocity ratio, Uj/U0, between the jet flow and the hot gas flow. The nearly concentric and more intense flame, possibly with a higher flame temperature, with a shorter radius was commonly formed with increasing oxygen concentration. This is consistent with the previous observation through particle false-color imaging [17] where the flame is described as the soot cloud around the devolatilizing particles [28]. In relatively lower oxygen concentrations, however, the volatiles were initially released around the coal particles, and the flame was less luminous and immediately elongated, showing tail-like behavior. Because one of the main parameters that would allow for the formation of the concentric volatile flame is obviously the oxygen concentration, an additional experiment was completed in the oxygen concentration of 45.0 and 50.0 %. The vectorial behavior related to non-spherical appearance of the volatile flame was quantitatively interpreted to represent the degree of asymmetric development of volatile flame. The circularity of the volatile flame formation was presented through the mean elongated distance (rc) and the mean inclined angle (hc) values of the volatile flames, as shown in Fig. 10. Once the volatile matter was released from the particle, the flame was leaning to one side. The direction of the tails was affected by the buoyancy and relative velocity of the particle to the gas flow, as shown in Fig. 9. In this study, the tail was gradually tilted towards the left with an increasing velocity ratio. This is considered to result from the momentum difference between the injection flow and the combustion product gas compared with the tail behavior in the previous co-flow configuration [15–17] and dropping into the quiescent gas [19,20]. Nearly concentric flame appeared in the higher oxygen concentration at more than 45.0 % oxygen, regardless of the penetration momentum of the jet flow (Fig. 10). 3.3. Dynamic variation of the size and shape of the volatile flames 3.4. Char oxidation (onset of apparent visible char flame or ignition) Existence of the volatile flame in this observation is based on the appearance of the visual images. The terminologies of ignition and extinction of the volatile flame are also used to represent the initial appearance and final disappearance of the envelop flame. As a first step in discussing the dynamic variation of the size of the volatile flame, we have already utilized the assumption of the spherically concentric volatile flame. It has been seen that this assumption would be acceptable only for the limited experimental condition. We first present experimental conditions when the volatile flame appears to be spherically concentric and when not. From the sequential observation of a single coal particle, the onset of char combustion or ignition can be related with the formation of luminous intensity emitted from the particle surface, which has already or simultaneously experienced the entire process of volatile release and combustion (Fig. 6). It was generally found that the oxidation of volatiles preceded the heterogeneous oxidation of coal char, if all the volatiles released from the particle are involved in the combustion reaction. However, overlapping of the volatile oxidation and the char oxidation stages was often revealed, as indicated in Fig. 11. In the case of a particle size 75 lm and an oxygen Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx 9 Fig. 9. Formation dynamics of volatile flame on different oxygen concentrations and flow velocity ratios (Uj/U0). Bituminous F coal, dp 125 lm. Photo was taken when the flame diameter reaches at its maximum. concentration of more than 34.6 % in this study, especially at the particle surface of the shape with a sharp point, heterogeneous ignition was almost overlapped with the apparent volatiles oxidation. The results are consistent with previous ignition regimes as a function of heating rate and particle size [29,30]. It was shown that a circumambient volatile flame prevented the char reaction by screening the solid from oxygen access on the left of the particle, in contrast with the direct char oxidation on the right surface of the particle (see Fig. 11(c)). Different degrees of radiant intensity arising from the char surface oxidation are relevant to the temperature variation of the luminous char particles. In a typical form, based on the wellknown gray body assumption and the Stefan-Boltzmann law, describing the total energy radiated from the particle, i=reApT4p where r is the Stefan-Boltzmann constant, e is the emissivity, and Ap is the projected surface area of particles, the particle temperature Tp is directly influenced by intensity variation because the emissivity is not precisely known as a function of temperature or wave length for most coals or chars [31]. The projected surface area of the moving particle can fluctuate a little (because the particles are not perfectly spherical). Contrary to the common modeling concept of uniform particle char combustion, it was observed from many particle traces that, in the initial stages, combustion on the particle surface is nonuniform. The phenomenon has been pyrometrically reported [24] and a relevant model has been built to describe it in the previous literature [23,24], now has been photographically confirmed. It was difficult to define the onset points of char oxidation considering this state of affairs; however, the series of images of the luminous char can be used for the discussion of char oxidation. Fig. 12 presents the quantified averaged-intensity from the char surface with parametric variation of the oxygen concentration along with the associated time scale. In the present study, the onset time of char oxidation, tchar_oxidation, is defined to the point where only char surface oxidation occurs after the simultaneous hetero-homogeneous reaction (see Fig. 6). The normalized intensity on the gray scale would correspond to the averaged value divided by the number of pixels of the projected surface of each particle at each frame, although the particle was partially burned. As a result, the values showed somewhat linearly increasing trends along with the time elapse in the graph even though a more luminous intensity was detected at the point of the particle with the increasing oxygen concentration. Oxidation of the char particle following the extinction of the volatile flame occurs at a different rate. As the oxygen concentration increases, the char combustion takes shorter time based on Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 10 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx Fig. 12. Averaged global intensity during char oxidation (from tchar_oxidation, refer to Fig. 6). Bituminous F coal, dp 125 lm. On the vertical axis, the normalized values 0 and 1 mean 0 (Min.) and 255 (Max.) in gray scale, respectively. The horizontal axis means the time from the beginning of char ignition. Fig. 10. Mean elongated distance (rc) and mean inclined angle (hc) to estimate the degree of asymmetric development of volatiles flame. [32] as q/k(PO2)n, where q is the burning rate per unit external surface, k is the kinetic rate, PO2 is the oxygen partial pressure determined by the oxygen concentration in the bulk gas, and n is the exponent. The parameters are subsequently related with the global intensity of char surface. The higher luminous intensity indicates a relatively more intense burning situation [13,33], a possibly higher particle temperature at the particle surface, which is assumed to be the surface radiation of a gray body. 4. Concluding Remarks Fig. 11. Overlapped combustion stages during particle entrainment. Typical situation (a) heat-up, (b) volatile (homogeneous) oxidation, (c) simultaneous (both homogeneous and heterogeneous) oxidation process, and (d) char (heterogeneous) oxidation. dp 75 lm, O2 34.6 % (or higher). the slope of the graph. The coal char particle with a non-spherical appearance was burned from the edge of the particles because of a different heat transfer gradient at the sharp point of the particle. One of the typical expressions of burning rate of char is given An experimental investigation on high magnification visual observation was carried out to elucidate the combustion behavior of single coal particles entrained into hot gas flow. The direct observation of instantaneous combustion behavior in the controlled environmental conditions is presented. Within the limits of the present experimental conditions, following conclusions and insights have been drawn: By showing the sequential combustion processes of particle heat-up, volatile release and oxidation, and char reaction in time and space, the half-shadow visualization of the burning particles was able to offer the positioning of the particles which led to the timing of the characteristic sequence of the sub-processes including the particle heat-up time (delay until the visual ignition) and the volatile burning time. Imaging quantification of the burning particles (coal being heated, volatile flame, and burning char) was conducted in terms of the changes of the apparent size, shape, and intensity based on its luminosity. Time-wise progress of the formation and extinction of the apparent volatile flame was presented. Oxygen concentration directly affected the appearance of the volatile flames. The degree of asymmetric development of volatile flames facilitated an interpretation of the effect of oxygen concentration. In the highly enriched oxygen range, volatile flames were observed to be nearly spherically concentric, with almost no effect of the relative speed of the particle to the mean gas flow. Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010 H. Lee, S. Choi / Combustion and Flame xxx (2015) xxx–xxx The onset of char combustion or ignition as evidenced by luminosity from the char surface was observed in this study. Initial appearance of luminosity was localized, and the char oxidation appeared to spread over the entire char surface. In some cases, the combustion appeared from the edge of the excessively polygon-shaped particle, while the volatile flame was still observable. This observation results were presented with a hope to stimulate discussions on the fundamental understanding of combustion stages of single coal particles. The limited set of quantitative observation data would help strengthen the capability of the predictive modeling of coal combustion, which is ultimately beneficial in utilizing the comprehensive computational codes. Acknowledgments The authors gratefully acknowledge support from the Korea Advanced Institute of Science and Technology (KAIST) and the Brain Korea 21+ project. References [1] L.D. Smoot, D.T. Pratt, Pulverized Coal Combustion and Gasification, Plenum Press, New York, 1979. [2] G.M. Faeth, Prog. Energy Combust. Sci. 3 (1977) 191–224. [3] J.M. Beer, N.A. Chigier, Combustion Aerodynamics, Applied Science Publishers, London, 1972. [4] L.D. Timothy, A.F. Sarofim, J.M. Beer, Proc. Combust. Inst. 19 (1982) 1123–1130. [5] S. Choi, C. Kruger, Combust. Flame 61 (1985) 131–144. [6] T.X. Phuoc, P. Durbetaki, Int. J. Heat Mass Transfer 30 (1987) 2331–2339. [7] V.S. Gururajan, T.F. Wall, R.P. Gupta, J.S. Truelove, Combust. Flame 81 (1990) 119–132. [8] S.C. Saxena, Prog. Energy Combust. Sci. 16 (1990) 55–94. [9] D.B. Anthony, J.B. Howard, H.C. Hottel, H.P. Meissner, Proc. Combust. Inst. 15 (1975) 1303–1317. 11 [10] S.K. Ubhayakar, D.B. Stickler, C.W. Rosenberg Jr., R.E. Gannon, Proc. Combust. Inst. 16 (1977) 427–436. [11] P.R. Solomon, M.A. Serio, R.M. Carangelo, J.R. Markham, Fuel 65 (1986) 182–194. [12] I.W. Smith, Proc. Combust. Inst. 19 (1982) 1045–1065. [13] C.R. Monson, G.J. Germane, A.U. Blackham, L.D. Smoot, Combust. Flame 100 (1995) 669–683. [14] A. Williams, R. Backreedy, R. Habib, J.M. Jones, M. Pourkashanian, Fuel 81 (2002) 605–618. [15] W.J. McLean, D.R. Hardesty, J.H. Pohl, Proc. Combust. Inst. 18 (1981) 1239–1248. [16] A. Molina, C.R. Shaddix, Proc. Combust. Inst. 31 (2007) 1905–1912. [17] C.R. Shaddix, A. Molina, Proc. Combust. Inst. 32 (2009) 2091–2098. [18] Y.A. Levendis, K. Joshi, R. Khatami, A.F. Sarofim, Combust. Flame 158 (2011) 452–465. [19] R. Khatami, C. Stivers, Y.A. Levendis, Combust. Flame 159 (2012) 3554–3568. [20] T. Maffei, R. Khatami, S. Pierucci, T. Faravelli, E. Ranzi, Y.A. Levendis, Combust. Flame 160 (2013) 2559–2572. [21] J.J. Andreopoulos, Fluid Mech. 157 (1985) 163–197. [22] W.R. Seeker, G.S. Samuelsen, M.P. Heap, J.D. Trolinger, Proc. Combust. Inst. 18 (1981) 1213–1226. [23] C. Wendt, C. Eigenbrod, O. Moriue, H.J. Rath, Proc. Combust. Inst. 29 (2002) 449–457. [24] Y.A. Levendis, R. Sahu, R.C. Flagan, G.R. Gavalas, Fuel 68 (1989) 849–855. [25] J.L. Meriam, L.G. Kraige, Engineering Mechanics - Statics, John Wiley and Sons, New York, 2008. [26] K. Matsuoka, H. Akiho, W. Xu, R. Gupta, T.F. Wall, A. Tomita, Fuel 84 (2005) 63–69. [27] R. Khatami, C. Stivers, K. Joshi, Y.A. Levendis, A.F. Sarofim, Combust. Flame 159 (2012) 1253–1271. [28] L.D. Timothy, D. Froelich, A.F. Sarofim, J.M. Beer, Proc. Combust. Inst. 21 (1986) 1141–1148. [29] H. Juntgen, K.H. Van Heek, Fuel Process. Technol. 2 (1979) 261–293. [30] J.B. Howard, R.H. Essenhigh, Proc. Combust. Inst. 11 (1967) 399–408. [31] R. Sahu, P.S. Northrop, R.C. Flagan, G.R. Gavalas, Combust. Sci. Technol. 60 (1988) 215–230. [32] R.E. Mitchell, O.H. Madsen, Proc. Combust. Inst. 21 (1988) 173–181. [33] G. Beeston, R.H. Essenhigh, J. Phys. Chem. 67 (1963) 1349–1355. Please cite this article in press as: H. Lee, S. Choi, Combust. Flame (2015), http://dx.doi.org/10.1016/j.combustflame.2015.03.010

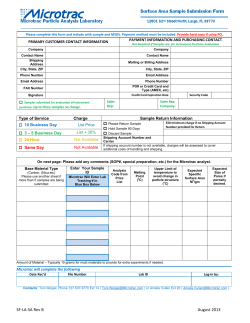

© Copyright 2026