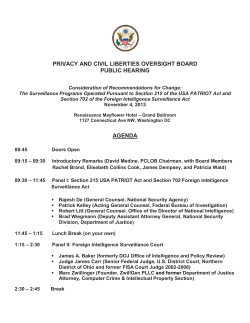

ADA BRICK PATTERN WET SET PANEL Product Features Detectable Warning Panels

ADA BRICK PATTERN WET SET PANEL ® Detectable Warning Panels 3 BRICK PATTERNS AVAILABLE: • Basket Weave (shown) • Herringbone • Running Bond Product Features • ADAAG Compliant • Approved by most DOT’s • 5 Year Manufacturer Warranty • Installs in Less than Half the Time of Standard Pavers • Very high Impact Resistance • Exceptional Strength • Extremely Durable • Outlasts and Out-performs All Traditional Pavers • No Plant Life or Weed Growth Between Pavers • No Elevation Deviation of Brick Height Due to Expansion & Contraction • Polymer Concrete Material • Homogenous Colors • Comes Fully Assembled • Color Matching Bolts • Easy to install • Simple to Replace Wet Set Panel Specifications PATTERN STYLE SIZE W x L x D PART NUMBER PART WEIGHT PALLET QTY. BASKET WEAVE RUNNING BOND HERRINGBONE 24” x 48” x 1/2” A6002448BRADA-XX A6002448RRADA-XX A6002448HRADA-XX 45 lbs. 45 lbs. 45 lbs. 15 15 15 www.armorcastprod.com 24” x 48” x 1/2” 24” x 48” x 1/2” TEL: (818) 982-3600 FAX: (818) 982-7742 ADA BRICK PATTERN WET SET PANEL INSTALLATION ® Detectable Warning Panels Recommended Wet Set Panel Instructions: 1. Follow all safety requirements that include but not limited to, State, Federal and/or Local safety standards. 2. Concrete mix shall conform to all requirements as specified by the contract document. 3. Tools required for installation are typical of those used by concrete finishers. 4. Do not remove the anchors or bolts before placement. Panel shall be placed in concrete with all the hardware attached. 5. After concrete is poured the contractor shall establish finished grade using mason line or other appropriate methods. The polymer concrete panel shall be placed on top of the concrete and tamped in place using installer’s weight or concrete vibrator to facilitate placement in a low slump concrete. Final panel elevation shall be verified. Replaceable Panels Replacement Instructions: 1. Simply unscrew bolts from panel. 2. Pry panel up and lift away. 3. Clean surface area. 4. Replace with new panel. 5. Screw bolts back into anchors. 6. Make sure the proper slope is obtained as specified in the contract document. 7. Low slump concrete may require 25 to 50 pound weights to weigh down panels after placement in concrete. 8. Steel edging trowel with a minimum of 1/8” radius shall be used to edge the finished concrete around the panel. 1/2” deep groove is required. Enlarged view DISTRIBUTED BY: 9. Once concrete is hardened, remove weights and panel protective cover. 10. Protect the installed tiles from pedestrian and vehicular traffic until concrete is hardened. Wet Set Panel Technical Data TEST DESCRIPTION Water Absorption @ 100˚ C Slip Resistance Compressive Strength Tensile Strength Flexural Strength Chemical Resistance Abrasive Wear Surface Flammability Smoke Density Flame - Rate of Burning Gardner Impact Geometry Hardness - Shore D Accelerated Service Test Freeze Thaw Fungus Resistance Test Salt Spray www.armorcastprod.com VALUE (Nominal) TEST METHOD ASTM ASTM ATSM ATSM ATSM ATSM ATSM ATSM ATSM ATSM ATSM ATSM ASTM ATSM ATSM ATSM D570 C1028 D695 D638 D790 D543 D2486 E162 E662-03 D635-91 D5420 w/ Geometry “GE” D2240 G154 “Cycle 4” C1026-87 (2002) G21 B117-03 0.35% 0.80 Minimum 24,000 PSI 11,000 PSI Yields at 6,000 PSI, No Failure No dissolution under common chemicals 0.020 inches max. after 1,000 abrasive cycles Less than 25 Less than 0.4 @ 1% / Less than 14 @ 4% Self Extinguishing 110 IN-LB, or 450 IN-LB/IN (min.) 75 <3 Delta E w/No Deterioration after 3,000 hrs. No Disintegration No Growth No Deterioration TEL: (818) 982-3600 FAX: (818) 982-7742

© Copyright 2026