2.7Mb - Australian Geomechanics Society

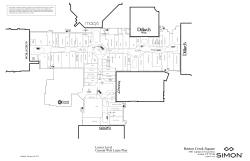

13/04/2015 Marina Bay Sands Integrated Resort The design and construction of the 16 hectare basement at Marina Bay Sands, Singapore 16th Mar 2015 Jack Pappin 2 600m • Ground conditions • Excavation sequence (area by area) • Issues (area by area) 3 Overall Development at Marina Bay Sands Integrated Resort 4 Overview of presentation 1 13/04/2015 5 Plan of 16 hectare excavation 6 Geological sections Thick deposit of soft clay. Severe time constraints - More than 40% of concrete construction works for substructure - Minimise inter-dependency between different contracts. Movement control for existing structures (ECP and BSB). Very limited site access. 7 Challenges for Excavation Works 8 Layout of excavations Site access 2 13/04/2015 Circular Cofferdams Jul 2007 9 View of site access 10 Minimum use of strutting Site access Design Jan 2008 Effective Wall Thickness To take into account: • Plan offset at commencement level • Verticality tolerance Design wall alignment t t = Wall thickness teff t PLAN teff = Effective wall thickness Maximum Hoop stress ~ K0 insitu stress * R / teff 11 MICE & Hotel Donuts & Hotel Peanut 12 Design of Circular walls 3 13/04/2015 As shear stress and in plane compression stress are mutually dependant the BS8110 friction coefficient for a plain concrete joint was used iteratively in the SAP analysis. 3-D Analysis for Peanut Cofferdam 1. 13 Obtain different earth pressures from OASYS FREW to account for variation in geology. 2. Set up 3-D Finite Element Model SAP2000 to assess stresses and deformation shape of the cofferdam 3. Structural design of diaphragm wall panels, cross wall and fin wall. Design of Circular walls 8m wide 15m deep cantilever fin walls Cross wall Location of peak inter panel shear 14 Design for shear in peanut cross wall Crystal pavilions Promenade Museum Retail Theatre MICE Casino Hotel Tower 1 15 Construction sequence – South Podium 16 Hotel Tower 2 Hotel Tower 3 Construction sequence – South Podium 4 13/04/2015 Existing Ground Level Retail STAGE 1: MICE RL(m) RL(m) 110 110 Sea 100 Existing Ground Level Existing Ground Level Existing Ground Level Diaphragm wall MICE Retail 99.5 mRL 1. Install diaphragm wall, jet grout and bored piles. 2. Excavate along perimeter of circular cofferdam to construct capping beam. MICE Retail Capping beam Capping beam Diaphragm wall 100 Fill 90 80 90 Proposed excavation level Sand Sand 80 6m thk. Jet grout Soft clay 70 70 60 4m thk. Jet grout 60 Old Alluvium 50 50 40 40 17 Construction sequence – South Podium 18 Bored piles Construction sequence – South Podium STAGE 2: STAGE 3: 1. Excavate to final excavation level inside cofferdams. 2. Install top down columns. 1. Install steel truss at +100mRL using trench method. 2. Construct part of L1 slab as construction access. 3. Cast base slab in cofferdams. B2 FEL (~+90.5) B4 FEL (~ +86.0) B4 slab RL(m) RL(m) Retail 110 MICE Top down column Retail 110 100 100 MICE L1 slab for construction access Steel truss Steel truss FEL B2 slab 90 90 Sand Sand 80 80 70 70 60 60 50 50 40 40 19 B2 slab Construction sequence – South Podium 20 Construction sequence – South Podium 5 13/04/2015 B2 FEL (~ +92.5) STAGE 4: 1. Excavate to final excavation level in MICE and +91mRL in the remaining areas outside cofferdams. 2. Construct basement structure inside cofferdams. +91mRL Construct basement slabs above B4 Construct L1 slab +91mRL B2 FEL (~ +90.5) RL(m) Retail 110 STAGE 5: B4 FEL (~ +86.0) B2 Slab RL(m) Retail 110 MICE B4 FEL (~ +86.0) 1. Cast B2 slab in MICE. 2. Install struts in the remaining area below B2 soffit. 3. Excavate to final excavation level in the remaining areas. B4 FEL (~ +86.0) MICE L1 slab 100 100 Strut below B2 FEL 90 Sand Sand 80 80 70 70 60 60 50 50 40 40 21 B2 slab FEL 90 Construction sequence – South Podium 22 Construction sequence – South Podium B4 slab STAGE 6: STAGE 7: B4 slab 1. Cast B4 slab. 1. Complete L1 slab. 2. Install struts across the openings of L1 in Retail. 3. Remove steel truss. B4 slab RL(m) Retail 110 100 MICE B4 slab L1 slab MICE Strut at L1 90 Sand Sand 80 70 70 60 60 50 50 40 40 Construction sequence – South Podium L1 slab previously cast L1 slab previously cast Retail 110 80 23 L1 slab previously cast RL(m) 100 90 G/F slab to be cast 24 Construction sequence – South Podium 6 13/04/2015 B2 slab to be cast STAGE 8: 1. Demolish cofferdam diaphragm wall to below B2. 2. Construct and connect B2. 3. Remove struts below B2. B2 slab previously cast B2 slab previously cast Hack Dwall to below B2 slab RL(m) Retail 110 100 MICE Hack Dwall to below B4 slab STAGE 9: 1. Demolish cofferdam diaphragm wall to below B4 slab. 2. Complete basement structure. B4 slab previously cast Hack Dwall to below B4 slab RL(m) Retail 110 MICE 100 B2 slab 90 90 Sand Sand 80 80 70 70 60 60 50 50 40 40 25 Construction sequence – South Podium 26 Construction sequence – South Podium Koden Test on every panel to check Verticality Recorder Koden Test Results 27 View of central 120m donut 28 Winch Unit Construction of cofferdams 7 13/04/2015 Steel truss against top of donuts to retain stability of donuts when excavating outside Inclinometer readings Excavation Steel Truss Layout A0 (+) B0 (+) B180 (-) A180 (-) GSA Analysis 29 Construction of cofferdams 30 Design of cofferdams Steel truss against top of donuts to retain stability of donuts when excavating outside 30,000 m3 8,000 trucks 31 Design of cofferdams 32 Removal of cofferdams above excavation level 8 13/04/2015 Oct 2008 33 Sequence for North Podium (a) (Casino – Retail) 34 Semi Top Down Excavation (Casino Area) South Podium North Podium Struts along Dwall 8m 17.5m Steel Truss Initial excavation 11m 17.5m Excavate North OR Excavate South 35 Semi Top Down Excavation (Casino Area) 36 3D analysis carried out to investigate stability of north donut 9 13/04/2015 Museum Retail Theatre RL(m) 100 90 Sand 80 70 60 50 Shear support to museum from the curved wall supported at ends 37 Museum C Wall 38 Museum C Wall Oct 2008 SAP model of circular with loads being transferred in shear to Old Alluvium at the ends. Lateral support at the ends provided by anchors on the north side and adjacent bored pile perimeter wall at south hear support to museum form the curved wall supported at the south side. 39 Museum C Wall 40 Excavation at DTE – DCS - Theatre 10 13/04/2015 DCS Theatres 200.00 210.00 220.00 230.00 240.00 CT DTE 250.00 260.00 270.00 280.00 290.00 310.00 320.00 330.00 Bridge 340.00 350.00 Benjamin Sheares 300.00 Lateral Force from the East of DTE 110.00 movement control 100.00 mm 40.00 84.5 30.00 Continuously Reinforced 20.00 Wall (Shear Wall) 26m 90.00 Lateral Force from East of DTE BSB 10.00 80.00 00.00 78 -10.00 70.00 -20.00 67 60.00 -30.00 -40.00 50.00 -50.00 -60.00 40.00 -70.00 -80.00 30.00 -90.00 20.00 Horizontal Displacement Contour -100.00 Large lateral soil load to be carried in shear to the DCS requires continuously reinforced shear cross walls to transfer load to Old Alluvium DCS box needs to resist large lateral earth pressure from the East of DTE DTE movement needs to be controlled to minimise impact onto BSB 41 DTE – DCS – Theatre Area : Issues 42 Continuously reinforced Shear Wall DTE – DCS – Theatre Area : Issues Theatres Extent of trench for female panels 43 6400 3000 Male panel (excavated after adjacent female panels are concreted) Female panel (only the middle portion is concreted) DTE – DCS – Theatre Area : Issues 44 Regular review of DCS performance 11 13/04/2015 Theatres 45 Regular review of DCS performance 46 Regular review of DCS performance Pier 19 N Benjamin Sheares Bridge - Elevation Pier 20 Pier 21 MBS Site Pier 21 47 Benjamin Sheares Bridge 48 Pier 22 South Abutment Benjamin Sheares Bridge 12 13/04/2015 Theatre DCS Theatre TBM Shaft DCS DTE DTE Dowell pins overstressed Inevitable movement to the bridge abutment 49 TBM Shaft Benjamin Sheares Bridge 50 Benjamin Sheares Bridge Theatre Underside of deck DCS TBM Shaft Deck crossbeam DTE Inevitable movement to the bridge abutment Allow articulation between the Pier and the Deck Section on Plan Pier crosshead View looking up from underneath 51 Benjamin Sheares Bridge 52 BSB Adjustable Shear Pins 13 13/04/2015 0 Adjustment dates 10 20 30 40 50 mm 53 Adjustment schedule 54 Permanent underslab drainage The end 55 14

© Copyright 2026