From start up to full Operation.

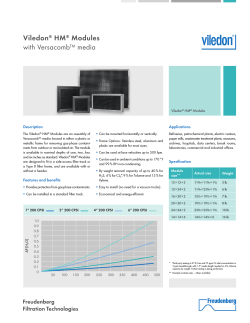

Accurate steam measurement: From start up to full Operation. Introduction Steam has often been described as the ‘lifeblood’ of industry. It is the medium by which heat from a boiler is converted into an easily transportable form that can provide diverse services from office heating to the mechanical energy that drives turbine generators. Steam is still one of the most popular methods of providing an energy source to a process and its associated operations. STARDOM allowed for full process control similar to what is expected a DCS with thethat lower cost point of a consumption PLC. It It is now afrom well-accepted fact measuring energy also tight integration withtoFAST/TOOLS to efficiency. allow for is anfeatured important factor in the quest improve energy rapid screen development and is data integrityto through data Efficient and accurate metering paramount determining buffering and backfill onan network orpicture serverof outage. excess use, along with accurate whereto the steam STARDOM allowed for full process control similar what is is being used. A sound management can only have expected from a DCSenergy with the lower cost policy point of a PLC. It a positive effecttight on the ‘bottom line’ also featured integration withprofitability. FAST/TOOLS to allow for rapid screen development and data integrity through data buffering and backfill on network or server outage. The Challenges Most boiler systems are scalable to the plant’s needs, meaning steam generation can be ramped up or down depending on the need from the facility. This can range from low flows during start up, to higher flows during full operation and back down to low flows during downtimes of maintenance. It is important however that accurate measurement of steam is essential in controlling boiler efficiency and safety. The more accurate and reliable measurements that are made, the more informed decisions can be taken that affect costs and product quality. Traditionally the most common of to steam metering is Only ONE STARDOM FCN wasmethod required guarantee total the orifice plare and differential transmitter technique. control of the pilot plant, makingpressure all the I/O connections General the areas of concern with this type of measurement are through following modules: the orifice plate’s susceptibility to wear introducing immediate theModules. relatively losses ·inaccuracies, 3 Analog Input Only ONE STARDOM FCNhigh waspermanent required topressure guarantee total into theplant, system by theallorifice plate and the small ·introduced 2 Analog Output Modules. control of the pilot making the I/O connections typically 3:1. ·measuring 2 Thermocouple Input Modules. through the range, following modules: · 3 Analog Input Modules. · 2 Analog Output Modules. · 2 Thermocouple Input Modules. One slot on the STARDOM FCN (including panel space) was left unused for future bus expansion, which could provide up to 25 modules if needed. One slot on the STARDOM FCN (including panel space) was left unused for future bus expansion, which could provide up to 25 modules if needed. All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation The orifice flow meter is not suitable for low-flow measurement, and can develop zero drift and span drift when the temperature/ pressure conditions fluctuate beyond the design specifications. In order to measure larger turn downs with a orifice, the plates must be changed periodically and the pressure transmitters re-calibrated and spanned. Vortex meters are known to be superior devices for steam flow measurement due to their inherent linear measurement, large turndown, low pressure drop and high accuracy. It is often thought that it is no problem to install a line size meter to capture a wide range of flows but is not always the case. practice of can PETRAMIN is athat company dedicated to theThis production lead to losing a lot of the low end measurement. Whenservices sizing a the alkyl-amines since 1983. Its production capacity vortex meter, it isdemand commonand to have to reduce theexport line size international enables them to its using productsreducers to manytocompanies around thethrough globe. the meter for concentric increase the velocity optimum performance. unfortunately piping changes need to PETRAMIN is a company dedicated to the production ofbe presence in Europe with the HQthe PETRAMIN has a strong made and this can increase installation costs. alkyl-amines since 1983.the Its production capacity services located in Spain. Its main are the international demand and markets enables them to Foundry export itsIndustry for the Automobile Sector and the Pharmaceutical Industry. products to many companies around the globe. Solution Customer Profile Customer Profile To meet the customers’ needs, Yokogawa introduced the presence in Europe with the HQ PETRAMIN has a strong digitalYEWFLO Reduced Bore Type Vortex Flow meter featuring located in Spain. Its main markets are thereducer Foundry Industry a cast stainless steel body and a concentric and PPC (Power Process Control) is a firm of engineers for the Automobile Sectorflow and the measurements PharmaceuticalinIndustry. expander thattoenable stable low-flow dedicated providing the bestrate solutions for Instrumentation, conditions. This expands the range of measurements that with can be valves and control systems technology in partnership performed, from the higher flow rates down to the lower end their manufacturers. PPC offers engineering support, preof theand flow span, which is normally difficult forfor Vortex Flow meters, sales, and isControl) a one stop control and PPCpost (Power Process is ashop firm of engineers andmeasurement ensures stable and accurate flow FAST/TOOLS rate output. SCADA, solutions, including dedicated to providing the best solutions for Instrumentation, STARDOM controls, instrumentation, other Yokogawa valves and control systems technologyand in partnership with products. their manufacturers. PPC offers engineering support, pre and post sales, and is a one stop shop for control and PPC executedsolutions, this application fromFAST/TOOLS conception through measurement including SCADA, Each Flange size commissioning and continues to support expand the STARDOM controls, instrumentation, andand other Yokogawa available in 3 bore system to meet PETRAMIN’s needs. sizes: products. Yokogawa Partner Profile Yokogawa Partner Profile Featured Solutions • Full Bore • 1 size PPC executed this application from conception through reduction commissioning and continues to support and expand • 2 sizethe FAST/TOOLS is a full-featured SCADA Host and HMI that reduction system to meet PETRAMIN’s needs. includes visualization, alarm management, historization, reporting, mobile interface, and trending. FAST/TOOLS supports scalable robust architectures with up to quad• Face to face redundant servers, zero deployment clients, FAST/TOOLS is a full-featured SCADA Host and and very HMI large that is the same as point counts (real deployments over 1 million points on a Standard unit. includes visualization, alarm management, historization, •reporting, Drop in server without single and interface, testing to and 16 million points). mobile trending. FAST/TOOLS piping changes supports scalable robust architectures with up to quadSTARDOMservers, represents family of controllers thatvery range from redundant zeroadeployment clients, and large the small DCS-like rackmounted hybrid controller (FCN) point counts (real deployments over 1 million points on a to the robust intelligent RTUto(FCN-RTU) for aggressive operating single server and testing 16 million points). environments, control, data-logging, web visualization, e-mail, FTP, and various specialty functions like AGAthat andrange API from STARDOM represents a family of controllers MPMS calculations. the small DCS-like rackmounted hybrid controller (FCN) to the robust intelligent RTU (FCN-RTU) for aggressive operating AN 2014-08-942 environments, control, data-logging, web visualization, e-mail, FTP, and various specialty functions like AGA and API MPMS calculations. Featured Solutions While formerly two to three different types of orifice plates had to be changed to adapt to fluctuations in the line flow rate, this is no longer necessary with the digital YEWFLO reduced bore type. This model reduces installation cost and expands the range of applications available to end user. The flow meter is available with a single reduction or a double reduction in bore size, while still keeping the same face to face dimension of a standard full bore vortex. This makes installations on new projects simplified with no need for additional reducers STARDOM allowed for swapping full process control similar Vortex to whatunits is or piping, and it makes already installed expected from a DCS with the lower cost point of a PLC. It simple, as there are no piping changes required. also featured tight integration with FAST/TOOLS to allow for rapid screen development andvortex data integrity through data Reduced bore digitalYEWFLO meters are flow tested buffering and backfill on network server outage. STARDOM allowed for full process control similar what is with the reducers; this ensures theoraccuracy of the to unit is not expected from by a DCS with the cost point reductions of a PLC. It compromised reductions in lower the line. Manual in also featured integration with FAST/TOOLS to allow for piping cannottight guarantee this accuracy. rapid screen development and data integrity through data buffering backfill on network or serverbore outage. The mainand benefits of Yokogawa’s reduced type vortex flow meter: • Minimum measurable flow up to five times lower than conventional vortex flow meter. • Integrated construction with reducers built into the flow meter body. • The same face-to-face dimensions ease the task of installing other sizes or types of digitalYEWFLO flow meters. • No need for costly piping modifications such as reducers/ expanders or short pipes to achieve the required straight pipe length. • Increases the space for installation of additional instrumentation Yokogawa vortex flowmeters are also well suited to high temperature applications, and the quality of flow management can be improved even further through the use of anti-vibrating efficiency and self diagnostic functions that rely on the PETRAMIN is SSP a company digitalYEWFLO's system.dedicated to the production of alkyl-amines since 1983. Its production capacity services the international demand them to the export its A multi-variable design isand alsoenables available. With multivariable products to many companies around the globe. option, a built-in integral temperature sensor allows the meter a company dedicated toofthe production of to PETRAMIN make a trueismass flow measurement saturated steam strong presence in Europe with the HQthe PETRAMIN has a alkyl-amines since 1983. Its production capacity services by referring to steam tables embedded in the software. This located the in Spain. Its main are the international demand and markets enables them to Foundry export itsIndustry eliminates need for separate pressure and temperature for the Automobile Sector andaround the Pharmaceutical Industry. products companies the globe. sensors andtoa many flow computer. Customer Profile Customer Profile Yokogawa Partner Profile PETRAMIN has a strong presence in Europe with the HQ located in Spain. Its main markets are the Foundry Industry PPC (Power Process Control) is a firm of engineers for the Automobile Sector and the Pharmaceutical Industry. dedicated to providing the best solutions for Instrumentation, Traditional Instrumentation valves and control systems technology in partnership with their manufacturers. PPC offers engineering support, pre Reducer Process and post sales, and isControl) aExpander one stop forengineers control and PPC (Power Process is ashop firmProcess of piping piping measurement solutions, including FAST/TOOLS SCADA, dedicated to providing the best solutions for Instrumentation, Short pipe Short STARDOM pipe controls, instrumentation, other Yokogawa Only ONE STARDOM FCN was required to guarantee total valves and control systems technologyand in partnership with products. control of the pilot plant, making all the I/O connections their manufacturers. PPC offers engineering support, pre Flow through the following modules: Upstream side 10D and post sales, and is a one stop shop for control and PPC executedsolutions, this application fromFAST/TOOLS conception through measurement including SCADA, commissioning and continues to support and expand the · 3 Analog Input Modules. STARDOM controls, instrumentation, and other Yokogawa Only ONE STARDOM FCN was required to guarantee total Down stream Upstream system to meet PETRAMIN’s needs. · 2 Analog Output Modules. products. control of the pilot plant, making all the I/O connections side 5D side 5D · 2 Thermocouple Input Modules. through the following modules: PPC executed this application from conception through commissioning and continues to support and expand the · 3 Analog Input Modules. FAST/TOOLS is a full-featured SCADA Host and HMI that system to meet PETRAMIN’s needs. · 2 Analog Output Modules. includes visualization, alarm management, historization, · 2 Thermocouple Input Modules. reporting, mobile interface, and trending. FAST/TOOLS Yokogawa Partner Profile Featured Solutions supports scalableSolutions robust architectures with up to quadFeatured redundant zero deployment clients, New Instrumentation Using Reduced Bore Typeservers, FAST/TOOLS is a full-featured SCADA Host and and very HMI large that Process One slot on the STARDOM FCNpiping (including panel space) was left unused for future bus expansion, which could provide up to 25 modules if needed. Flow Upstream side 10D One slot on the STARDOM FCN (including panel space) was left unused for future bus expansion, which could provide up to 25 modules if needed. All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation point counts (real deployments over 1 million points on a includes visualization, alarm management, historization, single server and testing to 16 million points). reporting, mobile interface, and trending. FAST/TOOLS Process supports scalable robust architectures with up to quadpiping STARDOM represents family of controllers thatvery range from redundant servers, zeroadeployment clients, and large the small DCS-like rackmounted hybrid controller (FCN) point counts (real deployments over 1 million points on a to the robust intelligent RTUto(FCN-RTU) for aggressive operating single server and testing 16 million points). Down stream side 5D environments, control, data-logging, web visualization, e-mail, FTP, and various specialty functions like AGAthat andrange API from STARDOM represents a family of controllers MPMS calculations. the small DCS-like rackmounted hybrid controller (FCN) to the robust intelligent RTU (FCN-RTU) for aggressive operating environments, control, data-logging, web visualization, e-mail, FTP, and various specialty functions like AGA and API MPMS calculations.

© Copyright 2026