The Preparation and Characterization of Hydrotalcite Membranes

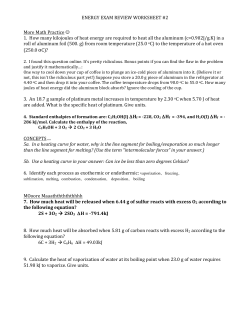

Mork Family Department of Chemical Engineering and Materials Science 2006 Student Symposium The Preparation and Characterization of Hydrotalcite Membranes Taewook Kim (Ph.D. Candidate) Advisors: Muhammad Sahimi and Theodore Tsotsis Global warming is caused by greenhouse gases such as CO2, CH4, NOx. Development of stable Mg-Al-CO3 hydrotalcite microporous membranes with high CO2 selectivity Biggest challenge: CO2 separation technology. (PSA, distillation, membrane technology) Hydrotalcite Novel inorganic membranes can be applied under harsh conditions. M(OH)2 Brucite-like layers ▶ Higher CO2 adsorption capacity at high temperatures ▶ Good thermal stability ▶ Easy to regenerate Interlamellar doamins [MIIII1-xMMIIIIIIx(OH) (OH)2]x]+x+[X [Xm-m-x/mnH nH2O] O]x-x[M 2 2 1-x x x/m Two different types of membranes have been prepared: Electrophoresis: colloids travel through a fluid in response to an applied electric field ■ Large-area membranes prepared by dip-coating, EPD (Electrophoretic deposition), and vacuum suction (w/ silicon treatment) methods on alumina discs or tubes . ■ Micro-membranes prepared on Si-wafers and stainless-steel discs. Adding the HT Etching with KOH -w/, w/o sublayer (γ-alumina) HT coated Si HT Membrane Micromembrane process MG70Dcoat Mg70Dparticle 4000 3500 α− alumina peak 3000 Intensity Silicon treatment HT + γ-Alumina coating Silicon wafer silicon layer HT layer HT peak 2500 5㎛ 2000 1500 1000 HT layer 500 0 10 ㎛ -500 10 20 30 40 2θ 50 60 70 Micromembrane XRD spectra Micromembrane 8.0E-09 8.0E-09 Permeance Permeance (mol/m22sec secPa) Pa) (mol/m 6.0E-09 6.0E-09 Memb 4.0E-09 4.0E-09 CO2 Ar 1.0E-11 1.0E-11 2.5 2.5 ddk (Ǻ ) k (Ǻ ) 33 ∆P 30psi N2 2.0E-09 2.0E-09 22 Gas (MW) Permeance × 10-8 (mol/m2 s Pa) 3.5 3.5 44 Permeance order : He> CO2>N2>Ar Su #1 He(4) 5.292 N2 (28) 1.18 Ar (40) 0.873 CO2 (44) 0.611 X 5K Vacuum suction membrane (before and after silicon treatment) Silicon treatment Vacuum-suction membrane Perm Permenace enace He 10 ㎛ X 5K Permselectivity ∆P He/gas Experimental Result 40 psi Ideal Knudsen value 30 psi 40 psi 4.93 1.0 1.0 1.0 1.24 0.883 0.604 2.65 3.16 3.32 4.52 6.08 8.72 3.96 5.60 8.15 (psi) Before coating 40 After coating Gas Permeance 30 Permeance [× 10-9 (mol/m2 s Pa)] N2 26.5 CO2 18.1 N2 24.9 CO2 17.5 CO2/ N2 Permeance 0.0159±0.0014 0.68 0.494±0.002 0.70 0.0165±0.0013 0.450±0.008 Permeance order : He> N2>Ar>CO2 CO2/ N2 silicon-coated on alumina membrane Permeance 31.1± 2.5 0.204 27.3± 1.8 0.204 CO2/ N2 9.6 1.97 10.0 2.04 Permeance order : CO2> H2>He>N2 □ A number of techniques have been developed and studied for the preparation of HT membranes. □ Different membranes have been tested for their permeation characteristics towards single gases and their mixtures. □ A number of the membranes were shown to be nanoporous, with some of them showing permselectivity towards CO2. The support of the U.S. Department of Energy is gratefully acknowledged.

© Copyright 2026