Document 105446

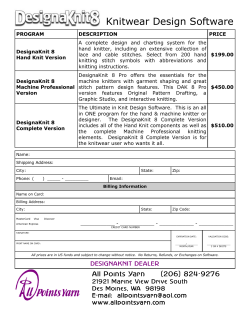

Seamless Knitting Technology and Trends 2012 Topic 1. Seamless History & Definition 2. Seamless Functional Features & application in the sportswear. 3. Seamless Sportswear Products: How to develop it 4. Seamless Sportswear Combination of Fashion and Function 5. Seamless Sportswear Market Trends – High performance / Low cost 6. Santoni Seamless machinery Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless History & Definition Year Historical Events Contributing to Development of Seamless Knitting 1589 William Lee in England invented the first flat-bed frame to create hosiery. 1798 The circular knitting frame is born. 1860 The first circular sock machines were small but heavy English and French hand cranked machines which produced circular stocking lengths. Early models go back as far as the 1860’s and were hand powered they could only produce narrow tubular lengths of knitted fabric. 1866 Clever inventors soon made improvements and machines were developed that could produce seamless stockings complete with turned heel and toe. In 1866 Mr Mac Nary from Saxony was one of those inventors. Circular hand powered knitting machines were widely circulated in the USA and Britain and gradually spread to most developed countries in the world. 1867 William Cotton of Loughborough patented his rotary-driven machine that used a flat bed to produce fully-fashioned garments. 1930 Spiers produced a succesful circular knitting machine with the revolving cylinder and internal sinker capable to knit garment-lengths with the tubolar rib border. 1938 The company Wildt Mellor Bromley introduced in the market the fully-automatic garment-length machinery able to produce rib, jacquard, transfer stitch, stripe, in the same garment. 1984 The the modern bodywear garment machine come to the market . The machine, whose simple construction owes much to knowledge gained from development of hosiery, tights, and body size circular knitting machinery. Few Italien Knitting manufactory start to develop this machine type. (OSGSandonini, Lonati, Sangiacomo) . 1988 Santoni becomes a company of the prestigious LONATI group. Started to relate his name to the “SEAMLESS” phenomenon. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless History & Definition • • Seamless technology can produce nearly finished products. Thus, seamless knitting has the capability for production time and cost saving. It reduces the traditional process of the production costs compared to traditional knitting. Seamless garment by body size circular knitting technique concept. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless History & Definition Streamlining the Manufacturing Process Dramatically Reducing the Number of Production Steps Conventional Knitting Ware housing Dyeing & Finishing Ware housing Layingout Cutting & Cleaning Side Sewing Waist Sewing Body Size Machines Knitting Ware housing Dyeing & Finishing Ware housing Seamless Machines Knitting Bottom Sewing Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Dyeing & Finishing Cutting & Cleaning Waist Sewing Bottom Sewing Side Sewing Bottom Sewing Seamless History & Definition • Between 1998-2001 seamless underwear production reached 9% of the total global production and 35% in 2007. • SEAMLESS was born as a phenomenon of collective custom, a sort of new way of approaching the apparel culture. • SEAMLESS production is at the same time strongly connected with the story and the evolution of SANTONI as a CompanySantoni belongs to Lonati Group - a worldwide leader in knitting machinery manufacturing Santoni started to develop the modern body size seamless machine in 1988 . • Santoni Shanghai starts seamless machinery production in 2005 .After more than 20 years the seamless technology flourished around the world. • Santoni group has expanded becoming the leader of the Seamless World Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Seamless technology is an innovative concept in clothing free of the side seams 9 Different stitch structures in different areas 9 Different kind of yarns in different areas 9Better And Wider Range Of Fit 9Invisible Comfort 9Freedom Of Movement 9Natural Softness 9Light, Smooth And Soft To Touch 9Performance Features Linked To Combination Of Fibers 9Smooth, Streamlined And Sleek 9Custom Apparel At An Affordable Cost Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear 9 Various stitches such as rib, net, jacquard, piquet, stripes, laces, as well as pre-shaped structures, hidden supports, pockets, collars and hoods. 9 Finished garment in a few minutes starting from the yarn and without passing through cutting and sewing operations. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear 9 Laid-in elastic yarns inserted in the welt bands and equipped with area shaving gradual compression featuring Tubular Fabrics without seams 9 Give direct way to the realization of finished products ready to be put into the commercial distribution channels, and reduce to a minimum the usual steps of the production process. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Unique two-layer construction the outside layer provides perfect microclimate for the skin, releases the sweat and keeps the skin dry. The inside layer assures better protection and keeps the natural body temperature Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Functional Features & application in the sportswear Protects from cold The two graphs demonstrate the speed and enhancement of the blood circulation in relation to wearing a traditional garment (fig.1) and a 3D Wear shirt made with fibres containing nanoparticles of Silver and Titanium (fig.2). Please note the considerable increase of the blood flow when wearing the new 3D Wear line in Tienergy fabric. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Products how to develop them • Before producing any sportswear, it is necessary to start from the right design study in term of function. You must decide on what kind of sports the application refers to and what will be worn for. You won’t wear the same thing for baseball as you do for basketball, and a tennis dress will not get you very far in a water polo match. FOCUS ON THE SPORT BEFORE YOU BEGIN DESIGNING WILL SAVE YOU TIME AND MONEY • Functional design for seamless sportswear knitted on body size circular knitting machine relates to: a) Moisture Management (sweat control) b) Thermal management (heat dissipation) c) Pressure management (muscle power) • To produce a high-quality seamless sportswear, it is also essential a correct finishing. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Products how to develop them • • • a)Moisture Management (sweat control) Moisture Management Fabric improves the sweat expelling effect. It can be designed and manufactured by the application of: 1) Functional yarn (combination and distribution of hydrophilic or hydrophobic fibers in fabric, capillary attraction benefited from special cross section) (coolmax, pp, tactel) 2) Fabric structure (plating for single jersey, sandwich structure for double jersey) b)Thermal management (heat dissipation) Dynamic heat control by power net: 1) Elastic yarn or fiber (Lycra, XLA, PTT) 2) Mesh structure (mesh size and distribution). c)Pressure management (muscle power) Fabric stretch properties design 1)Yarn (yarn elasticity) 2)Stitch structure (miss stitch distribution and density) 3) Knitting parameters (loop length, elastic yarn pre-elongation) Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Products how to develop them 3Dwear garments are characterised by the use of Lycra, Tactel, Meryl and Nylon yarns, which combine to produce elastic and flexible garments, developed for those who prefer a looser fit. Seamless technology actually eliminates stitching, allowing for the perfect adherence of the garment and the total harmony of body and fabric. 3Dwear Seamless accompanies and emphasises every movement, with breathable inserts which allow greater air circulation and the escape of excess heat. Ideal products for sportspeople: it is like a second skin as it is made to be very light, wrinkle-free, hard wearing and easy to look after and dry. RUNNING SHIRT Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Products how to develop them Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Combination of Fashion and Function A combination of «fashionable» with «functional» introduces the great outdoors to mainstream clothing, the idea is for sportswear to become both leisure wear and to retain its functional element. Seamless performance strap tank Weekender Seamless wool ski long tights underwear Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless Sportswear Combination of Fashion and Function Winter Sports Running Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Seamless wool ski long tights underwear Seamless wool ski long sleeve undershirt Seamless Sportswear Market Trends High-performance low/Cost As Chinese people’s life concept changing, more and more people are willing to spend money and energy on outdoor equipments, in order to achieve their target of sports. Professional sports apparel is an un-negligible part of sports equipment. And seamless sportswear is providing high performance with low cost. We believe it will be popular in the coming few years. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Santoni Seamless Machinery for sport wear Seamless Single Jersey Santoni China Productions CHN Wrap Seamless Santoni Italy Productions SM8-TOP2 E40 Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 SM4-TL2 Santoni Italy Productions SM8-TR1 SWD8 Seamless double Jersey Santoni Italy Productions SMDJ 2T CHN MF88 – New generation CHN model • • • The products made with this type of machine are night underwear for men and women; leggings for external use and sports leggings. Different kind of stitches that are possible to be produced: Single jersey; Fleece; Jacquard (with needles out work), Jacquard Vanise` (with one color yarns plus ground yarns in a single course), Mesh, Terry. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 SM8-Top2 E40 Circular single jersey Top2 HIE 8 feeds 40 E. To face the rising demand for the finer gauges, this machine which has an excellent record in seamless underwear has now been upgraded to knit in the finest gauges up to 40 E, while maintaining its advantageous features. The realizable products with this type of machine are the intimate garment for man and woman the swimwear for woman and the fine compression underwear and swimwear. . Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 SM8-TR1 Differents Brands are looking for TR1 machines to redefine the sportswear apparel This machine is widely accepted as the best machine for knitting sporswear garments because it can provide unique performance benefits . a special patented needle, allows to transfer the stitch on the single jersey machine creating an excellent quality mesh construction. The gauge of the machine starts to play an important role: 24 GAUGE- the same weight and look of the garment but wider yarn’ s count range and easiness of work with ecofriendly natural yarns. SM4 -TL2 Thanks to the reciprocal knitting action, machine can knit intarsio and three dimensional design 4 feeds single jersey circular electronic machine, having 2 selection points for every direction for knitting fishnet or jacquard inlay structure (Santoni patent). The machine allows knitting of seamlesswear single garments for underwear, outwear, swimwear, sportswear and sanitary garmen Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 SM9-MFS Circular Double Jersey SM9MF 12 feeds up to 20 E Santoni’s know-how and expertise for a Universal circular Seamless-wear machine. This is the most complete circular double jersey weft machine presented by Santoni recently on the world market that has required Santoni’s vast experience and knowledge so as to create this competent all around model. It will knit a vast range of both man made fibres as well as all types of natural fibres. This machine is Santoni’s latest “State of the Art” circular seamless model that can be typified in 3 words: Accessible, Versatile and Productive. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 SWD 6/2J Seamless warp machine SWD6/2J Keeping in mind that our users are garment manufacturers and by using our experience in knowing their needs well, the Santoni seamless Warp machine has many distinguished features that offer unique performance benefits. Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司 Thank you for your attention Factory #5-7-9, 2000 Wei Qing (E) Road , ShanYang Town, Jinshan Dist. 201508 SHANGHAI , P.R.CHINA Santoni Shanghai Knitting Machinery 圣东尼(上海)针织机器有限公司

© Copyright 2026