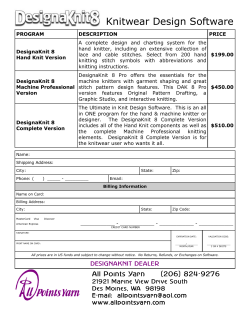

Document 105986