2013 Infiniti JX35 David Coakley / John Latimer

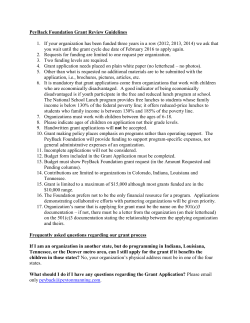

2013 Infiniti JX35 David Coakley / John Latimer Nissan Technical Center North America www.autosteel.org Infiniti JX35 www.autosteel.org What does the Segment look for? How does JX Win? Styling (Exterior/Interior) Seating Capacity/Room Safety Brand Experience Value for the Money www.autosteel.org Unique Selling Points for JX35 USP 1 : For Family Best Space and Packaging with Style USP 2 : For MOM Multi-Tasking and Smart Driving USP 3 : For KIDS and GRAND DAD/MOM Hospitable Interior for Children and Adults www.autosteel.org For Family- Interior Interior reflects Design Cues from the Award Wining Infiniti M Interior – Flowing shapes, high quality “Best in Class” Space” (Class defined as Ward’s Large Luxury CUV Segment) Best in Class Total Passenger Volume (149.8 cu. Ft.) Best in Class 1st Row Head Room and Leg Room Best in Class Cargo Space behind 2nd Row (3rd row seats folded flat. 2nd row seats in forward-most slide position) www.autosteel.org For Family- Exterior Grille Exterior design cues with the stunning Infiniti Essence concept “Clean”, not polarizing Double Wave Hood Crescent Cut D-pillar www.autosteel.org For Hectic Mom Infiniti Connection Telematics Service with Infiniti Personal Assistant Google Calendar integration Drive Zone & Speed Alert World’s First Backup Collision Intervention system (BCI) Next generation Around View Monitor with MOD (Moving Object Detection) Best in Class fuel economy Combined MPG (21 MPG) for FWD www.autosteel.org For KIDS AND GRAND DAD/MOM • 2nd row Seat Slide Function Long slide (5.5”) and tilt function provides class leading 3rd row • Unique Child Seat Folding Seat Feature on 40% side Easy access to 3rd row without removing a child seat in 2nd row. • Tri-Zone HVAC system It offers optimum comfort in each row, including 3rd row • Dual DVD Theater System Rear passengers can choose individual video sources (DVD, USB, VTR Jack) www.autosteel.org JX 35 Vehicle Exterior www.autosteel.org JX35 Development www.autosteel.org New development schedule Infiniti JX was NNA’s first V3-P project which is a shortened development schedule, key reductions are: Enhanced Digital phase activity by CAD data quality and CAE Physical phase schedule 19.5 month (6.5 month compressed) -16 -14 -12 -10 -8 -6 -4 -2 2 4 6 8 10 12 14 16 18 20 22 24 26 Previous development schedule Start SOP 26.0 month Digital Activity Prototype trial Production trial’s 6.5 month savings V3P schedule for JX Start Digital Activity 19.5 month 1st Trial Lot Production trial lot www.autosteel.org SOP Nissan Integrated Manufacturing System Concept of NIMS We can build more models We can build in ANY plant Reduced development for new models Conventional assembly line NIMS Increase by > 6 Models Production Model Capabilities 22% Reduction Tooling cost per additional model (B/Side, E/Con, PF) 4 Month Reduction Timing for tooling modification www.autosteel.org Strategy for Unibody vs. Frame Key Benefits of Improvement Ride & Handling NVH Body Stiffness Mass Reduction Fuel Economy www.autosteel.org D-Platform Strategy (common D-Platform design) Improved Roominess and 3rd row seat ingress/egress All new Platform for JX35 www.autosteel.org JX35 Torsion Targets Rear Torsion requires a higher target to make up for reductions in other systems: Tire width decrease for fuel economy improvement Mass reduction JX35 Competitor #3 www.autosteel.org JX35 Torsion Targets Several iterations of CAE were run to fine tune stiffness and increase mass reduction. Critical parts for Body stiffness are: Red = Primary Orange = Secondary www.autosteel.org Design Challenges www.autosteel.org Design Challenges Conventional Design JX35 Design Blue – Pathfinder RR Roof Section 40mm of headroom improvement Orange – JX35 Section Hinge was moved to improve head room www.autosteel.org Design Challenges Deep clearance pocket was required to eliminate Styling bump at Hinge area. This reduced section caused larger stress issues than expected in the digital phase Details on next slide www.autosteel.org Design Challenges UPR D-PLR HAS THICKER PARTS AND LESS REINFORCMENTS. ROOF DITCH HINGE LOCATION Hinge Loading www.autosteel.org Material Usage BIW UHSS utilization: High strength with reduced weight High strength performance Roof Crush Front Crash Side Impact Material Utilization Upper Body Utilization 35% UHSS by mass Platform 39% UHSS by mass www.autosteel.org Safety – Roof Crush www.autosteel.org IMPACT SAFETY (Roof Crush) The upper body construction minimizes the intrusion into the occupant compartment through the application of high strength steels. - Roof strength achievement with smaller section sizes to meet visibility and roominess targets. www.autosteel.org IMPACT SAFETY (Roof Crush) www.autosteel.org IMPACT SAFETY (Roof Crush) UHSS application and optimization: - 8.8kg mass savings in upper body - Approx. 20% performance improvement Baseline www.autosteel.org Final Safety – Rear Impact www.autosteel.org IMPACT SAFETY (Rear Impact) www.autosteel.org Safety – Side Impact www.autosteel.org IMPACT SAFETY (Side Impact) <Key points for side impact> <Body Structure> Designed to maintain integrity of the cabin in the event of a side collision by use of Multi-Load Path impact force dispersion structure and use of high strength steel. <Restraints> Side airbag Energy absorption airbags with separate chambers for chest/abdomen and pelvis areas allows for occupant injury reduction. Inflatable Curtain Occupants of all 3 rows are protected by the inflatable curtain airbags. <The Merit to Users> Safety Zone Body structure and efficient restraint systems allow for improved Safety performance. www.autosteel.org IMPACT SAFETY (Side Impact) www.autosteel.org IMPACT SAFETY (Side Impact) <Impact Force Dispersive Side Body Structure> Multi-Load Path Structure Side SILL reinforcement for dispersion to front and rear cabin www.autosteel.org Safety – Front Impact www.autosteel.org IMPACT SAFETY (Front Impact) <Key points for frontal crash> <Body Structure> Crushable zone Efficient Energy absorption side member structure was achieved with the use of high strength steel. Safety zone Designed to maintain its integrity in the event of a front collision by use of MultiLoad Path impact force dispersion and use of high strength steel. <Restraints> Seatbelts Pre-tensioner & load limiter are equipped for driver & passenger as Standard. Front Airbags SRS airbags are equipped for driver & passenger as Standard. <The Merit to Users> Body structure crushable zone & safety zone with efficient restraint systems allow for improved Safety performance. www.autosteel.org IMPACT SAFETY (Front Impact) <Key Points for JX35 Frontal Crash Body Structure > Multi-Load Path for Impact Force Dispersion Front pillar Front Side Member Side Sill Safety Zone: Rigid zone designed to maintain its integrity with minimal deformation to protect the occupants and the fuel tank. Crushable Zone: Crash energy management zone designed to absorb the energy generated upon impact. www.autosteel.org IMPACT SAFETY (Front Impact) Crushable Zone SIDE-MBR Structure Safety Zone Multi-Load Path for impact force dispersion Bottom view Side view www.autosteel.org Thank you! www.autosteel.org Great Designs in Steel is Sponsored by: w w w . a u t o s t e e l . o r g www.autosteel.org

© Copyright 2026