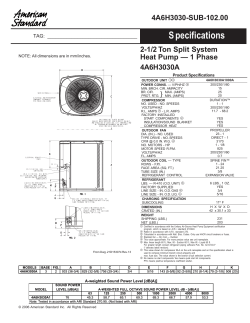

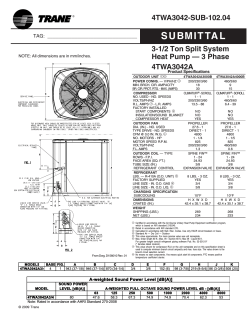

Features/ Benefits (cont)