Handcrafted Fishing Lures: The Art of Wooden Lure Making

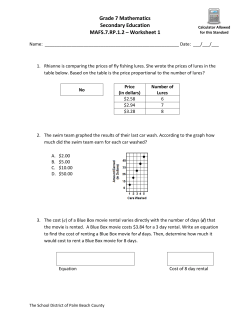

…Trolling Lures Hooks Aluminum Towers Rod Blanks Swimming Plugs SwivelS Soft Plastics Boat Lifts Handcrafted Fishing Lures Anchors Fighting Belts… MA E IN FLOD R SER IDA IES Mission Objective: Investigate & Reveal Target Acquisition Handcrafted Fishing Lures Have you ever wondered what goes into producing the tackle, gear and accessories we use today? Anglers and boaters often take for granted the tremendous effort it requires to engineer, design and manufacturer the countless components that combine to enhance our on-the-water experiences. You name it, and somewhere in Florida skilled craftsmen are dedicated to producing the finest equipment in the world. We wanted to learn more about these professionals and about the products they take such great pride in. We’re confident that you, too, will be fascinated with what we discover in our ongoing investigation. Staff Report 76 FLORIDA SPORT FISHING MAR.APR.2010 Handcrafted Fishing Lures ››› Similar to hunting, fishing originated as a means of providing food for survival. The harvesting of fish for substance likely began in prehistoric times when the methods of procuring a catch were quite primitive. The techniques and introduction of specialized tackle slowly evolved over time and while the earliest known lures were made of metal, it wasn’t until 1883 when the first wooden lure was offered to the Caption public. The introduction of wooden lures was a result of advanced techniques, as anglers looked to a more buoyant offering to entice game fish on the water’s surface. Introduced by Harry Comstock of Fulton, New York, and distributed by Pfleuger, the Flying Hellgramite is considered the first known wooden fishing lure. From the early 1900s, the firm of Heddon and Pflueger led the production of commercially made wooden lures. Except for a cult-like following of striped bass anglers in New England, the introduction of new-age materials and construction techniques have pretty much wiped wooden fishing lures off the market. Until now! For this edition of Made In Florida we thought it would be fitting to focus on a father and son duo that continues the tradition of handcrafting wooden fishing lures. Dr. Fred Hall, a semi-retired veterinarian, 78 FLORIDA SPORT FISHING MAR.APR.2010 MA E N FLOD RIDIA SER IES and his son David have enjoyed fishing Florida’s fertile waters for many decades. Having a deep love for both fishing and woodworking, they merged the two hobbies into a full-time business venture and have developed a very unique and highly effective series of lures. Located in Orlando, Florida, Hall Em In Lures is the proud producer of what are arguably the world’s finest handcrafted top-water plugs. 1 2 3 4 When it comes to fabrication, it should come as no surprise that the process starts with wood selection. Depending on the desired action, weight, and density, Spanish cedar, cherry, maple, walnut or hickory lumber is selected. Spanish Cedar is used as the standard selection for most of their lures because of its density, lightweight attributes and superior strength. Custom orders can also be fulfilled, with wood selection significantly affecting the buoyancy, retrieve and action. The lumber arrives in 5/4 planks and before the process can begin the timber is inspected for quality control. It’s essential to check the density of wood, as older growth cedar is much more desirable. Over the years the forestry industry has worked on methods to accelerate the growth of trees. They’ve accomplished this through science, but the faster-growing trees aren’t as dense as old growth lumber. The older trees produce much stronger wood that’s not as porous. When the planks are selected they are cut to size so they are easier to handle (Image 1). The planks are then measured (Image 2) and cut into 6” sections (Images 3 & 4). Depending on the desired finished product, a rattle may or may not be installed. If a rattle is selected, the 6” blanks are cut in half and a hole is bored through the middle or both pieces. A single flange 7mm glass rattler is placed in the hole and the two components are then epoxied back together. Without the use of cutting edge technology or advanced CNC machines, these FLORIDASPORTFISHING.COM 79 E IN MADRIDA FLO RIES ‹‹‹ Handcrafted Fishing Lures SE 5 6 Without the use of cutting edge technology or advanced CNC machines, these works of art are manufactured one at a time strictly by hand. 7 8 10 80 FLORIDA SPORT FISHING MAR.APR.2010 works of art are manufactured one at a time strictly by hand. The timber blanks are turned on a lathe (Image 5), which requires an extraordinary amount of skill and patience to create a product of exacting specifications. A variety of gouges, chisels and parting tools are used to shape the timber (Image 6). The lure starts to take shape and is sanded to create a smooth surface (Image 7). Once the lure has been turned, knurled and sanded, it is cut off the remaining block (Image 8) and the ends are sanded smooth (Image 9). The lures are then taken to a drill press where they are pre-drilled for the appropriate hardware (Image 10). Various jigs and templates are utilized to pre-drill the plug for molded eyes and hook hangers. 9 11 The lures are then impregnated with a lacquer sealer (Image 11). The sealer bonds to the wood and repels water intrusion if damaged by a toothy predator or errant cast. From here the lures hang dry. Next, an oil-based Zinsser primer is adhered to the wood (Image 12). The plug is then sanded with 600 grit sandpaper and another coat of primer is applied. After a final sanding the plug is now ready to be hand painted (Image 13). A skilled artist applies approximately five coats of enamel (Image 14) and the plug is set aside to cure for 24 to 48 hours. Finally, each lure is then sprayed with either a silver or gold fleck. From here, it’s time to install the molded eyes (Image 15). Next comes the hand-dipping process, and since these offerings are made one at a time they gather approximately 100 lures to streamline the process. The finishing process is the most time consuming of all. Utilizing a two-part epoxy, which has an approximate pot life of 45-minutes, each lure is hand-dipped tail to head (Image 16) and placed on a hanging rack to cure for an additional 24 to 48-hours (Image 17). Once cured, the lures are sanded to remove any bubbles or minor imperfections. The plugs are once Handcrafted Fishing Lures ››› again hand-dipped from tail to head. After another curing and sanding session the lures are finally ready for the third and final dip. The last coating is applied from head to tail to even out resin coverage and increase the lures overall durability. 12 The reason the first two resin coatings are applied tail to head is so there will be a buildup of resin along the head. Toss a typical plug over and over and you will surely notice scratches in the lure’s finish where the front treble hook swings. Hall Em In Lures’ unique dipping process eliminates the possibility of marring the durable epoxy finish. After the third and final dip the excess resin on the head and tail is removed with a belt sander, and the hardware holes are drilled again to 14 remove any excess resin. From here, 1” Because of the personal touch applied to each and every lure, these museum-quality offerings deserve to be displayed in the nearest art gallery, as much as they do your tackle bag. to 1-¼” stainless steel screw eyes are positioned (Image 18). Next, 2x split rings and special order 6x VMC black nickel hooks are installed (Image 19). At this 16 stage other variations such as fore and aft spinners can also be installed. After carefully scrutinizing each and every aspect of the lure’s finish and symmetry, the finished product is placed in a plastic case where it is ready to be shipped to anxious anglers across the country (Image 20). While woodworking is an art form in itself, creating handmade wooden lures that offer consistent symmetry and enticing action is an even more difficult trade. Because of the personal touch applied to each and every lure, these museumquality offerings deserve to be displayed in the nearest art gallery, as much as they do your tackle bag. Through independent field research and extensive testing the 19 father son team of Fred and David Hall has succeeded in combining modern day components with old world craftsmanship to achieve optimum performance in casting, durability and most importantly, fish catching effectiveness. FSF MA E N FLOD RIDIA SER IES 13 15 17 18 20 81 FLORIDASPORTFISHING.COM

© Copyright 2026