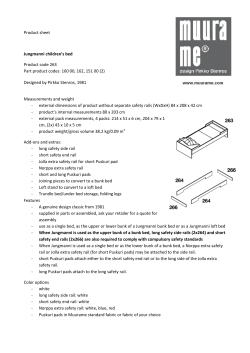

United States Consumer Product Safety Commission