Beckhoff News 05|2015

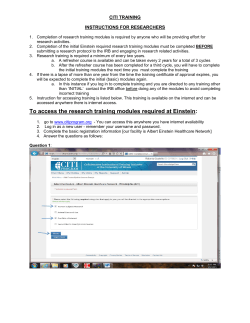

News | 05 2015 CP37xx | Multi-touch Panel PC with Intel® Atom™ multi-core processors With the CP37xx series, a Panel PC with multi-touch can be used directly in the field. The devices in a slender aluminium housing feature complete IP 65 protection and are designed for mounting arm installation. The Panel PCs offer high computing power with Intel® Atom™ processors with up to four cores. Due to its two independent Ethernet interfaces the CP37xx is ideally suited as a compact central processing unit for an EtherCAT control system. There is a choice of seven different multi-touch TFT displays in sizes between 12-inch and 24-inch and in 4:3, 5:4 or widescreen 16:19 formats. The Panel PC features an integrated rotatable and tiltable mounting arm adapter for a 48 mm diameter mounting arm tube. The wiring area can be opened easily without dismounting the device from the mounting arm. It offers fast access to the IP 65 connectors for power supply, Ethernet and optional USB or RS232. The CP37xx is equipped with one or two CFast cards. www.beckhoff.com/CP37xx News | Industrial PC 2 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com 11.6-inch displays complement widescreen multi-touch panels The product range of the CP2xxx and CP3xxx multi-touch panel series is completed by 11.6-inch devices with a resolution of 1366 x 768 in 16:9 format. The widescreen displays are available as built-in Panel PCs as well as Control Panels (built-in and IP 65 variants). Like all Beckhoff multi-touch panels, they feature a high-quality aluminium housing milled from a solid block with metal perimeter protection for the display front. With the new display size the range of application now offers a total of nine device options: 7-inch, 11.6-inch, 12-inch, 15-inch, 15.6-inch, 18.5-inch, 19-inch, 21.5-inch and 24-inch. The multi-touch panel series offers maximum flexibility: different display sizes, horizontal or vertical orientation, 4:3 or widescreen, built-in or IP 65 mounting arm installation. www.beckhoff.com/multi-touch CP27xx | Multi-touch built-in Panel PC with Intel® Atom™ multi-core processors The CP27xx built-in Panel PC series is designed for installation in the front of a control cabinet. The CP27xx combine reliable Beckhoff Control Panel design with state-of-the-art Industrial PC technology. The right display size is available for every application. CP27xx Panel PCs are equipped with Intel® Celeron® ULV 1.4 GHz or with Intel® Atom™ multi-core processors and have one or two CFast cards. Due to its two independent Ethernet interfaces the CP27xx is ideally suited as a compact central processing unit for an EtherCAT control system. A third independent Ethernet interface is available as an option. An optional PCIe module slot offers the possibility to extend the PC, e.g. with additional Ethernet interfaces. www.beckhoff.com/CP27xx 3 We reserve the right to make technical changes. C6915-0010 C6925-0030 News | Industrial PC Fanless control cabinet IPCs with Intel® Atom™ multi-core processors The control cabinet Industrial PCs C6915-0010 and C6925-0030 are now also available with Intel® Atom™ processors with one, two or four cores for scalable control solutions. The C69250020 is also available with Intel® Celeron® ULV 1.4 GHz CPU. The C69xx Industrial PC series is designed for installation in control cabinets. The compact aluminium housing of the C69xx Industrial PCs is equipped with a 3½-inch motherboard. Cooling of the C6915 and the C6925 requires no fan. The basic configuration of the C6915 and C6925 features a CFast card, thus creating PCs without moving parts. A hard disk or a second CFast card can be integrated in all of the PCs of this series as an option. www.beckhoff.com/C6915 www.beckhoff.com/C6925 4 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com C6670 | Many-core control Industrial server for control cabinet installation In combination with TwinCAT 3, two Intel® Xeon® processors, each with 6, 12 or in future also 18 cores on one motherboard with two Gigabit Ethernet controllers and a powerful graphics card produce a machine or plant controller that offers computing power for completely new ideas. Apart from the extremely high performance, up to 2048 GB DDR4 RAM, one PCIe Gen2 x4, one PCIe Gen3 x8 and four PCIe Gen3 x16 plug-in card slots are also available for several interface cards for video evaluation. Long-term availability is ensured for the processors and the motherboard. www.beckhoff.com/C6670 5 We reserve the right to make technical changes. EtherCAT Coupler Colour coding signal type Additional functions, e.g. relays or DIP switches Safety plug-in modules: – EJ1904: 4-channel digital input, TwinSAFE – EJ2904: 4-channel digital output, TwinSAFE – EJ6900: TwinSAFE PLC Digital and analog plug-in modules Motion modules Status and diagnostic LEDs Machine-specific connection level News | I/O Highlights – – – – – – – – – – very compact EtherCAT I/O solution made by Beckhoff: the inventor of EtherCAT reduced installation costs application-specific connector interface safety integrated use of cable harnesses avoids wiring errors modular and flexible based on the same technology as the Beckhoff EtherCAT Terminals, the largest EtherCAT I/O portfolio on the market optimised for high-volume production improved diagnostics 6 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com “Plug & Work” – Bus Terminals for circuit boards The EtherCAT plug-in modules are electronically-based on the well-known EtherCAT I/O system, while their design allows them to be directly attached to a circuit board. The circuit board is an application-specific signal distribution board that distributes signals and power to individual application-specific plug connectors in order to connect the controller to machine modules as required. Elaborate manual wiring of single wires, common in conventional control cabinet construction, is replaced. In combination with industrially manufactured cable harnesses, the signal distribution board – a circuit board specially designed by the user or by Beckhoff – distributes signals and power supply between the EtherCAT plug-in modules and the machine. The unit costs are lowered through the automated production of circuit boards and cable harnesses. The risk of incorrect wiring is reduced to a minimum, since the EtherCAT plug-in modules and the plug connectors of the cable harnesses offer coding options. The manufacturing process can be accelerated as far as possible and the risk of wiring errors is minimised. This saves working time and thus costs. It allows production at different worldwide locations with a minimum of risk, since errors are avoided through automation and coding. 9 Machine module 1 9 Machine module 2 Signal distribution via single-core wiring 9 Machine module 1 9 Machine module 2 Signal distribution via signal distribution board www.beckhoff.com/EtherCAT-plug-in-modules Latching grid Mechanical coding 7 We reserve the right to make technical changes. Stepper motor terminals with vector control The EL70x7 EtherCAT Terminals are intended for stepper motors with low (EL7037) or medium (EL7047) performance range. The PWM output stages cover a wide range of voltages and currents. Together with two inputs for limit switches, they are located in the EtherCAT Terminal. The EL7037/EL7047 can be adjusted to the motor and the application by changing just a few parameters. Stepper motors from the AS10xx series can be operated with vector control. This control technique offers various benefits, such as better dynamics and lower power consumption. www.beckhoff.com/EL7037 www.beckhoff.com/EL7047 www.beckhoff.com/AS1010 News | I/O Standard IP 20 components for increased industrial requirements In addition to the extended temperature range (-25… +60 °C), Beckhoff now offers I/O and Embedded PC products with coated electronic components. The coating protects the components against environmental influences. I/O and Embedded PC products can be ordered on request with PCB coating. These products are functionally compatible with the standard products. The increased mechanical load capacity of many of the I/O products opens up new application options for the I/O system, thanks to approval for an extended shock and vibration range. These components are vibration-resistant up to 5 g and shock-resistant up to 25 g. The standard Beckhoff I/O terminals are thus not only characterised by increased temperature and weather resistance, but also by high mechanical strength. New uses and applications with requirements that go beyond the standard application can be realised. +60 °C -25 °C www.beckhoff.com/IO www.beckhoff.com/CX 8 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com IO-Link devices extend the portfolio Since October 2013, the IO-Link communication system has been available worldwide as an international standard (IS) according to IEC 61131-9 and is thus the first globally standardised technology for communication with sensors and actuators below the fieldbus level. Based on this standard Beckhoff offers a new, extensive range of IO-Link box modules with IP 67 protection for digital and analog sensors for the implementation of inexpensive pointto-point connections directly in the field. With their compact and space-saving design the IO-Link box modules are suitable for the most diverse applications. The IO-Link connections are integrated in the proven plastic housings (EPI) and in the die-cast zinc housings (ERI) for additional protection in extremely harsh environments. The modules are connected via an IO-Link master, e.g.: – EL6224 EtherCAT Terminal (IP 20) – EP6224 EtherCAT Box (IP 67) – KL6224 Bus Terminal (IP 20) www.beckhoff.com/IO-Link-box Precise load cell analysis in IP 67 With the IP 67-rated EP3356, the functionality of the proven, IP 20-rated EL3356 eXtreme Fast Control (XFC) EtherCAT Terminal is now also available for decentralised installation in the field. It enables the direct connection of a resistor bridge (strain gauge) or a load cell with 4-wire connection technology. With automatic self-calibration (which can be deactivated if desired), dynamic filters, support for distributed clocks and a scanning rate of up to 100 μs, the EtherCAT Box is ideal for the fast and precise acquisition of signals from load cells, torque or vibration sensors. www.beckhoff.com/EP3356 The flexible gateway between different worlds of control in IP 67 The EP9300-0022 EtherCAT Box connects PROFINET RT networks to the EtherCAT Box modules (EPxxxx, EQxxxx and ERxxxx) and converts the telegrams from PROFINET RT to EtherCAT. One station consists of an EP9300-0022 and any number of EtherCAT Box modules. The box is connected to PROFINET RT via a d-coded M12 socket. In EtherCAT, the PROFINET RT box has at its disposal a lower-level, powerful and ultra-fast I/O system with a large selection of EtherCAT Box modules. The EP93000022 supports the PROFINET RT profile and fits seamlessly into PROFINET RT networks. www.beckhoff.com/EP9300 9 We reserve the right to make technical changes. TwinSAFE SC (TwinSAFE Single Channel) With the aid of the TwinSAFE SC technology it is possible to make use of standard signals for safety tasks in any network or fieldbus. To do this, EtherCAT Terminals from the areas of analog input, postition measurement or communication (4…20 mA, incremental encoder, IO-Link, etc.) are extended by the TwinSAFE SC function. The data from these extended EtherCAT Terminals is fed to the TwinSAFE Logic, where they undergo safetyrelated multi-channel processing. In the Safety Logic the data originating from different sourc- es is analysed, checked for plausibility and submitted to a “voting”. This is done by certified function blocks such as Scale, Compare/Voting (1oo2, 2oo3, 3oo5), Limit, etc. For safety reasons, however, at least one of the data sources must be a TwinSAFE SC component. The remainder of the data can originate from other standard Bus Terminals, drive controllers or measuring transducers. In this way, it is possible to use all the process data existing in the system for the safety technology. The TwinSAFE SC technology thus opens up com- pletely new possibilities in the Beckhoff system world and offers a simple, efficient and inexpensive possibility to fully integrate the safety tasks into the existing infrastructure. With the aid of the TwinSAFE SC technology it is typically possible to achieve a safety level equivalent to PL d/Cat. 3 in accordance with EN ISO 13849-1 or SIL 2 in accordance with EN 62061. www.beckhoff.com/TwinSAFE-SC TwinSAFE SC I/Os Analog input EL3124-0090 EtherCAT Terminal, 4-channel analog input 4…20 mA, differential input, 16 bit EP3174-0092 EtherCAT Box, 4-channel analog input ±10 V or 0/4…20 mA, differential input 16 bit EL3214-0090 EtherCAT Terminal, 4-channel analog input PT100 (RTD) for 3-wire connection EL3314-0090 EtherCAT Terminal, 4-channel thermocouple input with open-circuit recognition Position measurement EL5021-0090 EtherCAT Terminal, 1-channel SinCos encoder interface, 1 VPP EL5101-0090 EtherCAT Terminal, incremental encoder interface Communication EL6224-0090 EtherCAT Terminal, IO-Link terminal 10 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com TwinSAFE SC TwinSAFE SC EL6910 EL3124-0090 Analog signal EP3174-0092 Analog signal Safe analog value processing with TwinSAFE SC EL6910 EL3214-0090 PT100 EL3314-0090 Thermocouple Safe temperature monitoring with TwinSAFE SC News | TwinSAFE 11 We reserve the right to make technical changes. Power supply module Axis modules Alignment for simple mounting Status display EtherCAT interface Connection for external brake resistor Power supply 100…230 V AC (1~, 3~), 400…480 V AC (3~) Power supply for 24 V DC control voltage One Cable Technology (OCT) motor circuit 12 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com 4 digital inputs, e.g. safety, capture, enable AX8000 | Multi-axis servo system The AX8000 multi-axis servo system greatly simplifies the implementation of multi-channel drive solutions. The required number of 1-channel or 2-channel axis modules are attached to the central supply module. The modules are connected without screws or tools using the built-in AX-Bridge quick connection system, which is based on spring-loaded terminals. The 1-axis and 2-axis modules can optionally be equipped with TwinSAFE for safe drive technology. TwinSAFE The EtherCAT-based AX8000 multi-axis servo system combines powerful FPGA technology with multi-core ARM processors. An optional TwinCAT 3 runtime enables programming in C++, IEC 61131 and MATLAB®/ Simulink®. The new multi-channel current control technology realises extremely short sampling and response times. The entirely hardwareimplemented current controller combines the advantages of analog and digital control technology: reaction to a current deviation from the setpoint value is possible within 1 µs; the velocity controller cycle time is around 16 µs at a switching frequency of 32 kHz. The processing of EtherCAT process data (actual and setpoint values) is carried out without a processor almost without delay in the hardware, so that the minimum EtherCAT cycle time is only 62.5 µs. The AX8000 multi-axis servo system supports OCT, the One Cable Technology for power and feedback from Beckhoff. In connection with the servomotors from the AM8000 series, the wiring is reduced to the standard motor cable, via which the feedback signals are also transmitted. www.beckhoff.com/AX8000 News | Motion AX-Bridge connects 24 V DC, EtherCAT, DC-Link 13 We reserve the right to make technical changes. XTS: New motor modules for even more production flexibility With new motor modules, the high flexibility of the eXtended Transport System (XTS) has been increased yet again. The straight and curved motor modules (180°) are supplemented by new variants with a radius of 22.5° or 45°. Matching guide rails are also available for the new motor modules. The range of applications can now be further extended: – individual track layouts – flexible rotary indexing table – full circle with movers running around the outside – full circle with movers running around the inside – polygon, circle segments connected with straight sections – step- and S-shaped track layouts – rounded-off rectangle with a freely selectable size AT2025 AT2020 AT9020 www.beckhoff.com/AT2000 www.beckhoff.com/AT9000 AT9025 AT2040 News | Motion XTS mover with 12 rollers The AT9012 mover is optimised for applications that require a highly rigid guidance. The rollers of the mover are not pre-loaded by a spring strut. In contrast to the AT9011 mover with six rollers, the AT9012 mover has twelve rollers. It uses a set of six rollers for running on straight sections and a further set of six rollers for optimised running through the curve of the AT9050-0500 rail. www.beckhoff.com/AT9012 14 Product announcement For availability status of the new products see Beckhoff website at: www.beckhoff.com TwinCAT 3, Build 4018 – New features Build 4018 of TwinCAT 3.1 provides users with new and extended functions for the automation software. In addition to general performance updates, it contains many new features in the area of connectivity as well as improved diagnostic functions. Other new items include the integration of TwinCAT PLC HMI, numerous Motion Control functions, e.g. reading from and writing to I/Os or the new MultiCam function block, as well as optimised downloading and quicker verification for TwinSAFE. www.beckhoff.com/TwinCAT3 News | Automation TC3 Bode Plot Base In the TwinCAT 3 Measurement package, the TC3 Bode Plot Base is integrated license-free as a further analysis tool in Microsoft Visual Studio®. The Bode plot is a method commonly used in drive technology to determine the behaviour of a drive axis including its mechanics, so that it can be purposefully optimised. The Bode plot can be carried out in speed or torque modes. With the possibility to simulate various filters in TwinCAT Measurement, from the first-order low-pass filter to the second-order phase correction filter, coupled with the results of the Bode plot, the reaction of the axis to the set filter can be estimated even before it is activated in the drive controller. Thus machine commissioning can be considerably simplified. TC3 Scope View – Extended functionality TC3 Scope is a software oscilloscope for monitoring machine commissioning and data analysis in the production process. Scope View, which is integrated in Microsoft Visual Studio®, can be operated in stand-alone mode or in parallel to a TwinCAT project. The classic application is the continuous visualisation of variables in a chart. For many applications it is also useful to display a variable curve over a second variable which is not time – a so-called XY plot. The XY plot is already included in the license-free basic version, and with the Professional version this new display method is also available for the integration of scope control into your own .NET-based HMI. Further new features simplify orientation in the recorded measuring data, such as signal highlighting, overview chart in the time chart and the fast data picker. In addition, new data export formats are offered in the scope. www.beckhoff.com/TE1300 15 We reserve the right to make technical changes. DK1312-0415 This flyer gives a short overview of the new products; for further information see the Beckhoff News catalog 05'2015 or www.beckhoff.com/news Products online At www.beckhoff.com you can get detailed information on the range of products from Beckhoff. Animations, videos and interactive online presentations supplement the large variety of information. www.beckhoff.com Print media online The Beckhoff catalogs and flyers are available for download on the Internet. Printed copies are available on request. Please use our online order form to specify your requirements. www.beckhoff.com/media No. 1 | April 2015 www.pc-control.net 16 | cover Many-core control: Automation technology with endless possibilities 8 | products Beckhoff Drive Technology: PCc_01_2015_GB_v5.indd 1 Main catalog 40 | worldwide Husky, Canada: High-precision control AX8000, the new high-performance, technology lowers consumption of raw multi-axis servo system materials in injection molding machines 25.03.15 11:33 PC Control magazine Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered trademarks of and licensed by Beckhoff Automation GmbH. Other designations used in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owners. © Beckhoff Automation GmbH & Co. KG 04/2015 The information provided in this brochure contains merely general descriptions or characteristics of performance which in case of actual application do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressively agreed in the terms of contract.

© Copyright 2026