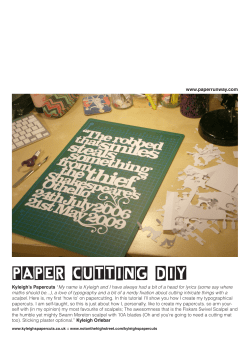

Document 122713