Lectured by: Prof. VIRGIL GEAMAN Transilvania University of

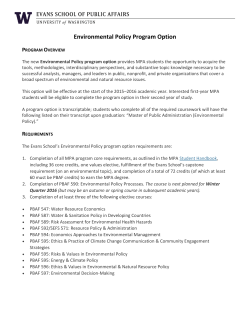

Lectured by: Prof. VIRGIL GEAMAN Transilvania University of Brasov, Romania IISS’15 KARABUK – TURKEY (01-03 April 2015). Departments: Materials and Welding Engineering Materials Science Bachelor’s degree programmes – full-time education Industrial Engineering field: Welding Engineering ; Industrial Safety Engineering Materials Engineering field: Materials Science; Computer Science in Materials Engineering Engineering and Management field: Economic Engineering in Mechanics Master’s degree programmes – full time education Industrial Engineering field: Welding Engineering of Advanced Materials Materials Engineering field: Engineering and Management of Advanced Metallic, Ceramic and Composite Materials Ph.D. programmes Industrial Engineering field: Materials Engineering field: supervisors supervisors Technology; Equipment used; Applications: ◦ ◦ ◦ ◦ Powder consolidation Healing of casting defects Diffusion bonding Food processing Hot Isostatic Processing (HIP) ◦ Application of high temperature and high pressure to remove internal porosity, consolidate powder for alloys, and diffuse bond. ◦ Materials that can be HIPped: Titanium, beryllium, steel, aluminum, superalloys; Castings, ceramics, etc. Food processing. Alloys are sometimes created using Powder Metallurgy Alloys have trouble becoming chemically homogeneous When they are allowed to form on their own they form large grains that do not mix as shown at right Using HIP it is possible to construct an alloy that has good chemical homogeneity and refined microstructures Small grain size, compared to previous slide, can be seen at right Leads to improved mechanical properties Turbine blades Need for a blade that has cooling channels to encounter high temperatures Using HIP it is possible to form a component from multiple components that are diffusion bonded Can maintain low weight while being able to withstand high temperatures and stresses Components can be joined through Hot Isostatic Processing using Diffusion Bonding Two materials undergo no more than a few percent macroscopic deformation Important because welding and fastening produce larger deformation which leads to stress points and weakening of material Surfaces of materials to be joined bond’s collapse and join with each other. The material is then bonded with a 100% perfect bond Barely detectible interface of diffusion bonded material seen at right Pressure vessel contains entire process Furnace enclosed in vessel Pressure vessel insulated from furnace Allows combination of high temperature and high pressure Pressures reach 200 MPa Temperatures reach 2000 degrees Celsius Size of pressure vessel ranges from smaller than 4”X12” up to 46”X80” HIP EQUIPMENT The aluminum alloys are offering the highest degree of hardness by heat treating. The development of the range of these alloys is determined by the fact that alloying is enlarging the possibilities of precipitation hardening. The particularities of the final heat treatment made to pieces from duralumin alloys – obtained through plastic deformation – especially through forging or extrusion, are determined by the characteristics of the plastic deformation structure. The paper presents the influence of the heat treatment applied to pieces made from duralumin alloys, before and after isostatic compaction. There are presented experimental results, conclusions of these experiments and are given some proposals for new technologies with positive effects over the specific industry. Casting defects such as internal pores causes weakness in materials Dark spaces at right are internal pores Voids act as stress risers Leads to inaccuracy when predicting yield and ultimate strengths, scatter With HIPping it is possible to change the material to a plastic state, collapse the voids, and bond the voided surfaces together (right) The result is a stronger material that has less scatter with ultimate and yield strengths. Accomplished though creep mechanisms and/or compressive plastic deformation Lot No. Tensile strength [N/mm2] Compression strength [N/mm2] Elongation [%] Classic test CIP test Classic test CIP test Classic test CIP test 1 131.2 148.0 297.8 336.2 8.92 16.65 2 129.2 142.2 292.6 331.7 7.74 16.90 3 120.4 139.2 287.1 328.2 8.16 16.07 4 118.4 135.0 287.6 335.3 7.16 15.90 5 119.8 137.3 288.7 334.6 7.86 15.82 Lot No. Compacting time [min] 1 0 2 5 3 10 Lot No. 1 2 3 4 5 6 7 8 9 10 Initial porosity [%] Compacting time 1.723 [min] 1.723 0 5 1.723 10 15 20 1.723 25 30 1.723 35 40 1.723 45 Porosity after applying classical heat treatment [%] Initial porosity [%] 1.723 1.723 1.723 1.723 1.723 1.723 1.723 1.723 1.723 1.723 Porosity after applying classical heat treatment 1.723 [%] 1.688 1.723 1.688 1.612 1.612 1.544 1.502 1.544 1.454 1.376 1.502 1.123 0.876 1.454 0.542 Porosity after classical heat treatment with CIP applied in the incubation period [%] Porosity after classical heat treatment with CIP applied in the incubation 1.723 period [%] 1.723 1.671 1.531 1.452 1.324 1.131 1.022 0.007 0.000 0.000 1.671 1.531 4 15 1.452 5 20 6 25 7 30 1.723 1.376 1.022 8 35 1.723 1.123 0.007 9 40 1.723 0.876 0.000 10 45 1.723 0.542 0.000 1.324 1.131 From this analysis it clearly results that the porosity is quickly eliminated, respectively at the same time of compaction the number of pores is decreasing with approx. 20-25%. All mechanical properties are increasing with a medium value of 16.54 N/mm2 for Tensile strength, with 42.44 N/mm2 for Compression strength and with 8.30% for Elongation. The hardened alloy is becoming mild and formable (as after solid-solution quenching), if it is reheated a short period 0.5-2 minutes, at the temperature of 250oC, process called reversion. It is also useful from technological point of view, as high formability from the incubation period after quenching. According to these aspects, the authors are proposing a new technological way of compaction by using cold isostatic pressing process, for the given duralumin alloy, with the following parameters: ◦ P = 120 MPa; T = 20 oC; t = 40 min. The old technology used by applying CIP at the final treatment supposed: ◦ P = 150 MPa; T = 20 oC; t = 60 min. The new variant proposed gives us the following advantages: the working pressure can be reduced substantially; the time of exposure can be also reduced in comparison with the classical technology. Although this decreasing in time is major in the case of an industrial production, it has an essential role concerning the productivity and with the decreasing of working pressure, all the components of the high pressure equipment are protected, which leads to the growing of working life and security in exploitation. By analyzing the experimental results, it can be concluded: - after fast cooling, the hardness decreases in all cases - comparing to the hardness after plastic deformation; - after ageing, the hardness of the samples is increasing, but not so high as after applying CIP treatment in the incubation period. The fact gives us the right to say that after plastic deformation, it must be applied the final heat treatment for the pieces that need higher hardness under working conditions - and we especially recommend this type of treatment - with applying CIP treatment after solid solution quenching - in the incubation period. HPP is the application of hydrostatic compression in the range of (100-1000) MPa that is capable of inactivating microorganisms. In the early 1990s, Japan and other nations introduced the use of HPP of food to inactivate barosensitive microorganisms. An advantage of HPP is the minimal effect it has on covalent bonds; thus, minimal damage occurs to flavors, aromas, provitamins, and vitamins. A brief review of high-pressure biotechnology in medicine and pharmaceutical sciences discusses some effects of HPP action on biological substances. HPP has been successfully applied to RTE meats, seafood, marinated raw meats, and some processed fruit and vegetable products. However, HPP caused product damage to watermelon, raw apple slices, and bread. In Figure 1 is presented an HPP unit for food processing, designated for preparing packaging food with discontinuous movement. Microorganism type Comments Food Sausages Enterobacteriaceae and Listeria 500 MPa for 5 min = 80°C for 40 min. Milk L. monocytogenes, Salmonella, and E. coli O157:H7 Required multiple passes for pressures <300 MPa. at 46-60°C, prior to Dynamic High Pressure (DHP) enhanced killing. DHP less effective than HPP. Best if total bacterial load <105. Juices and organic acid liquids S. aureus, Bacillus spp., L. moncytogenes, E. coli O157:H7, Salmonella Enteritidis, S. Typhimurium, yeast 8-log10 reduction at 345 MPa at 50°C - 5 min. except for S. aureus. Most vegetative cells are sensitive to 700 MPa, but not spores. 8-log10 reduction in yeast at 304 MPa at 25°C, pH 4.0 for 10 min. Generally, Gram-negative bacteria are more sensitive to HPP. Yogurt, jams, jellies, juices, tomato sauces, and other acidic products, fish, sliced meats Multiple pathogens Use where spores are not an issue as they cannot grow out at low pH. Variable pressure sensitivities with various commodities. Exponential phase is more sensitive than stationary phase. Strain to strain variability is greater for HPP than other processes. Net volume decrease, proteins may enature, gelation may occur, lipid phase changes may occur, increased ionization of dissociation. Eggs E. coli Accumulation of injured cells at pressures less than 400 MPa. Biphasic inactivation of E. coli at 5°C vs. linear exponential at 25°C. Vegetables and general Small size and cocci Mechanisms of pressure resistance. Small size and cocci shape are generally more resistant to HPP. Specific porins increase resistance. HIP enables to adjust fine, isotropic microstructures in duplex stainless steels, which is fundamental to attain high strength - high toughness combinations. Valve bodies and manifolds for oilfield uses can be produced by hot isostatic pressing of duplex stainless steel powders. Hot isostatic pressing enables to produce bi-metallic compounds by powderpowder or by powder-solid body bonding. The method is successfully applied for cladding of more ore less complex shaped parts like valves. Hot isostatic pressing enables to produce hollow structures by HIPing of a pipe or tube system with a metal powder. The realization of internal cooling passages is a typical example. Hot Isostatic Pressing has long been an essential process in the production of high-performance cast and PM parts for critical applications. Thanks to the recent development of higher capacities, shorter cycles, and precise control systems, HIP today is significantly more cost-effective, and will be even more so in the future. As a result, this proven technique is becoming economically justifiable to a growing number of manufacturers, and innovative new applications are continually being tested and adopted. There are a lot of phenomena that occur to make a good practice for industrial application in the field of HIPing consolidation for metallic or ceramic materials. But these phenomena are very difficult to be controlled. In the last years a lot of scientist are trying to give more details in this field to help the designers to have more complete data bases for practice use. [1]. Boeckeler, B.C. -“Development of Keziz Process”, Keziz Seminar, Kennametal, Inc., Latrobe, PA, September (1971). [2]. Hebeison, J.C. - “HIP Technology – The State of the Art After 50 Years”, HIP International Conference, Paris, France, May 22-25, (2005). [3]. Mashl, S.J. - “The Metallurgy of Hot Isostatic Pressing”, HIP Seminar, Grand Rapids, MI, October 24-25, (2001). [4]. Hebeison, J.C. - “HIP from Aerospace to Automotive”, HIP Seminar, Grand Rapids, MI, October 24-25, (2001). [5]. Zimmerman, F.X. Toops, J. - Hot Isostatic Pressing: Today and Tomorrow, Avure Technologies, Inc. www.avure.com [6]. Semlitsch M. & Dawihl D. - Basic requirements of alumina ceramic in artificial hip joints balls in articulation with polyethylene cups. Technicals principles, design and safety of joint implants. Hogrefe & Huber Publ, Seattle, pp. 99-101 (1994). [7]. Lerouge S. & Sedel L. - Alumina ceramic in total joint replacement. HIP Surg, pp. 31-40 (1998). [8]. Masson B, Willmann G, Von Chamier W. - Fiabilite ´du couple alumine-alumine dans la prothe`se totale de hanche. Journe´es lyonnaises de la hanche, pp. 397-402 (1999). [9]. Burger W. & Richter H.G. - High strength and toughness alumina matrix composites by transformation toughening and in situ Platelet Reinforcement (ZPTA) The New Generation of Bioceramics. Bioceramics, Vol. 13 pp. 454-548 (2000). [10]. Garino J.P. - The status and early results of modern ceramic-ceramic total HIP replacement in the United States. Bioceramics in HIP joint replacement. 5th Symposium CeramTec Stuttgart. Ed Thieme pp. 88-91(2000). [11]. Stewart T.D., Tipper J.L., Insley G. et al. - Wear of alumina matrix composite ceramics for HIP prostheses, ISTA-San Francisco, California, USA pp. 24-27 (2003). [12]. Willmann G. - Survival rate and reliability of ceramic femoral heads for THA. Material Science and Engineering, Ed. 29, Issue 10, pp. 595-604 (1998). [13]. Atkinson H.V. & Rickinson B.A. - Hot isostatic processing, Adam Hilger Series, Great Britain, (1991). [14]. Geamăn V. - Theoretical and experimental researches regarding to isostatic processing of poured blanks made from non-ferrous alloys, Ph.D. Thesis - "Transilvania" University of Braşov, (1995). [15]. Geamăn V. - Proc. Int. Conf. Hot Isostatic Pressing, Andover – Massachusetts, U.S.A., pp. 221-223 (1996). [16]. Ratke L. - Lectures on sintering. Institute for space simulation DLR Cologne Germany, (1993). [17]. Froes F.H. - Fourth International Conference on Isostatic Pressing, Journal of Materials, U.S.A. MA. (1991). [18]. James P.J. - Isostatic Pressing Technology, in Metals and Materials, Nr. 10, pp. 541- 546 (1992). THANK YOU FOR YOUR ATTENTION !

© Copyright 2026