Futuristic working fluids for Refrigeration and Air conditioning

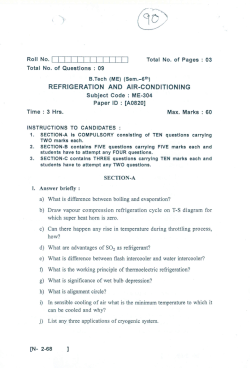

International Journal of Latest Trends in Engineering and Technology (IJLTET) Futuristic working fluids for Refrigeration and Air conditioning Systems - A Review and Outlook P. Elumalai Assistant Professor, Department of Mechanical Engineering Paavai Engineering College, Namakkal, Tamilnadu, India. R..Vijayan Professor, Department of Mechanical Engineering Government College of Engineering, Salem, Tamilnadu, India. M. Premkumar Professor, Department of Mechanical Engineering Paavai Engineering College, Namakkal, Tamilnadu, India. Abstract: A refrigerant is a working fluid used in a heat cycle for enhancing energy efficiency, by a reversible phase conversion from a liquid to a vapor. It comprises the main property of vapor to liquid and liquid to vapor. Coventionally, fluorocarbons, especially chlorofluorocarbons were used as refrigerants, but they are being forbidden because of their effects on ozone depletion. In this paper, a review of available alternative refrigerants and their physical, chemical properties vast literature survey have been carried out. Selection of efficient, eco-friendly and safe refrigerant for future has been attempted in this paper through discussions. Keywords – Refrigeration, Refrigerants, Global warming, zero Ozone Depleting Potential, Air conditioning I. INTRODUCTION Refrigerants have been extensively used in several areas in the industry for a long time. After finding the harmful effects of CFC based refrigerants on the ozone layer, the search to find alternatives to these working fluids gained more interest in the recent few years. Finding drop-in replacements for Chlorofluorocarbons based working fluids is important due to their harmful effects on the ozone layer and international conventions are requesting to reduce their usage. B.O. Baoji et al [1] experimentally investigated the performances of three ozone friendly Hydro fluorocarbon (HFC) refrigerants R12, R152a and R134a. R152a refrigerant found as a drop in replacement for R134a in compression system. the process of selecting environmental-friendly refrigerants that have zero ozone depletion potential and low global warming potential. R23 and R32 from methane derivatives and R152a, R143a, R134a and R125 from ethane derivatives are the emerging refrigerants which have non toxicity, low flammability and environmental-friendly. In these refrigerants need theoretical and experimental analysis to calculate their performance in the system. S. Wong wises et al [3,5] found that 6/4 mixture of R290 and R600 is the most refrigerant to replace HFC134a in a domestic refrigerator. Bagola [4] investigated the exergy performance of R12 and its substitute (R134a and R 152a) in the domestic refrigerator. R152a successes better than R134a in terms of COP and exegetic efficiency Miguel Padilla et al [2] found that R413A (mixture of 88% R134a, 9%R218, 3%R600a) can replace R12 and R134a in domestic refrigerator. Molina et al (1974) have been expanded into a comprehensive and very complex theory emphasis about 200 reactions that CFCs are significantly destroyed by UV radiation in the stratosphere. In the year 1987 Hoffman predicted 3 % global ozone depletion with contact of CFCs emissions of 700 thousand tone /year [4, 5,].Studied the performance analysis of alternative new refrigerant mixtures as substitute for R12, R134a and R 22. Refrigerant blend of R290/R 600a (40/60 by wt. %) and R 290/R1270 (20/80 by wt. %) are found to be the most Vol. 5 Issue 2 March 2015 447 ISSN: 2278-621X International Journal of Latest Trends in Engineering and Technology (IJLTET) suitable alternative among refrigerants tested for R12 and R22. Abishiek Tiwari et al [7] published a review paper on recent development on domestic refrigeration. Alkali Bane Agrawal et al (10) worked on eco-friendly refrigerant as a substitute for CFC (Chlorofluorocarbon). The binary mixture in the ration of 64% and 36% of R290 and R600a found to be a retrofit or drop in substitute of R12 for use in the compression refrigeration trainer. A performance comparison of vapor compression refrigeration system using various alternative refrigerants. A theoretical performance study on a conventional compression refrigeration system with refrigerant mixtures based on HFC134a, HFC152a, HFC32, HC290, HC1270, HC600, and HC600a was done for various ratios and their results are compared with CFC12, CFC22, and HFC134a as useful alternative replacements [17]. The activities of HCFC and HC-290 refrigerant mixture computationally as well as experimentally and found that refrigerant mixture 7/3 as a promising alternative to R12 system. R. Cabello et al [16] studied the influence of the evaporating pressure, condensing pressure and superheating degree of the on the performance of a refrigeration plant using three different working fluids R134a, R407C, R22. Fig.1 Vapor compression refrigeration cycle Jacob Perkins, an American citizen, obtained a patent in 1834 on a compression refrigerating system using ethyl ether in a closed circuit. The patent covers all the elements of the modern compression system, the compressor, the condenser, the expansion valve and the evaporator. From this time there began a search for the ideal refrigerant, which has not yet been, and which perhaps never will be discovered. Perkins used ethyl ether, in his early experiments but later graduated to an organic material produced by the heating of Indian rubber. Ethyl ether is not a good refrigerant because it is both anesthetic and flammable as well as requiring a large swept volume per unit of refrigerating effect. Ethyl ether is denser than air and has no strong smell, thus making it particularly dangerous in an age when illumination was by lamp or candle. It is not comprehensible what components were contained in Perkins’ quintessence from India rubber, but all who came in contact with it, which has been reported that it had an ineffably bad adore. II. HISTORY The traditional refrigerants like ammonia, SO2 and CO2 had been secluded and they were available for use, but complex compressors and prime movers were required to use them and for a while, the original refrigerants, air and water, competed with the water/ammonia absorption machine in the production of artificial cold. None of these refrigerants can fight with the compression system in terms of efficiency. Air, which is used in the Brayton cycle, produces a very low thermodynamic efficiency because of the large temperature range through which the cycle. Water is difficult to use efficiently because of the very low pressure and enormous pumped volumes which are involved. Absorption systems are notoriously inefficient but require a minimum of high-grade energy. However, it is Vol. 5 Issue 2 March 2015 448 ISSN: 2278-621X International Journal of Latest Trends in Engineering and Technology (IJLTET) impossible to imagine more compassionate substances than air or water. Ammonia, being part of the natural nitrogen cycle, is also completely benevolent in environmental terms. Compression refrigeration continued to use the highly flammable ethyl ether, though in 1863 Charles Teller took out a patent on the use of methyl ether, which operated at higher pressure and thus reduced the risk of drawing air into the system and forming an explosive mixture within the machine. Compression systems were improved by James Harrison in Australia but continued to use methyl ether, which was also used by Carl von Linden in 1875. Linden is generally considered to have pioneered the use of ammonia, but the first ammonia compressor for refrigerating purposes was designed and constructed by David Boyle in 1872, 4 years before the first Linden ammonia machine. Boyle produced up to 200 ammonia compressors prior to 1884, mostly for the shipping of beef from Texas. Ammonia is in many respects the ideal refrigerant but it has always had competition from less toxic substances. As early as 1862, Thaddeus Lowe developed a carbon-dioxide refrigerating system using a compressor he had developed for compressing hydrogen for observation balloons during the Civil War. Carbon dioxide has very low toxicity but requires high-pressure machinery and is difficult to use because of its low critical temperature (31.6 o C). Before the end of the 19th century, a fourth practical refrigerant, methyl chloride, had appeared in France, being used for the first time as a refrigerant in 1878. Methyl chloride was the forerunner of the wide range of halocarbon refrigerants, which came to prominence later. However, methyl chloride is odorless, but both are flammable and toxic, which gave the several serious accidents. In practice, methyl chloride proved to be much more dangerous to use than either SO2 or ammonia. SO2 is highly toxic but has a strong smell, which provided warning of any leak. Ammonia is also highly toxic and can be smelled at even lower concentrations than SO2. III. PRESENT REFRIGERANTS All HFCs, HFOs and HCFCs refrigerants brings us to the present day. The only single-component HFC in common use as a refrigerant is R-134a, which is a good match for R-12. Replacements for R-22 and R-502 have been creating by blending components to produce the required properties. In general, blends of volatile substances will evaporate to dryness through a temperature range known as ‘‘glide’’. Some blends however evaporate at a constant temperature; these blends are known as zoetrope. Glide is considered to be inconvenient so blends are generally selected to have zero, or minimal, glide. Such blends are zoetrope or near-zoetrope. Zoetrope are given refrigerant numbers in the 500 range. The actual numbers have no significance beyond indicating the order in which the blends were accepted by ASHRAE. Current requirements for a successful blend are that it should have an Ozone Depleting Potential (ODP) of zero, that it should be efficient to use in conventional refrigeration machinery, which should be non-toxic, nonflammable, and that it should have low global warming potential (GWP). It is very difficult to meet all these requirements. The only methane derivative which comes anywhere near is R-23, and it has a very high GWP. The only acceptable ethane derivatives are R-134a and R-125. It becomes observable that flammable substances have to be pressed into service, provided they can be included in blends which are non-flammable and do not fractionate to flammable. The flammable substances R-32, R-161, R-152a and R-143a can be added to the list of possible blend components. This still provides only seven substances from which to permutated halocarbon refrigerants for today and for tomorrow. Attention turns to derivate of propane but, out of 45 such compounds, only R-227, R-236 and R245 are apparently suitable. None of these substances has a normal boiling point which makes it very suitable for commercial refrigeration. Another problem which arises when considering substances which are derivatives of propane, butane, or even heavier hydrocarbons, is that the critical temperature, and therefore the latent heat, of such substances tends to decrease as the molecular weight increases. It is a serious disadvantage for a refrigerant to have a low critical temperature and a low latent heat. A major disadvantage of all the HFC refrigerants is that they have relatively high GWPs compared to the natural refrigerants. IV. ALTERNATIVE REFRIGERANTS A.CO2 CO2 is substance that it has virtually no impact on global warming or ozone depletion. CO2 is also nontoxic in small doses but concentrations over 5% can be lethal. It is also cheap and nonflammable, but when used as a refrigerant, CO2 (which is called R-744) requires extremely high operating pressures compared to R-134a. B. HFC-152a - Vol. 5 Issue 2 March 2015 449 ISSN: 2278-621X International Journal of Latest Trends in Engineering and Technology (IJLTET) HFC-152a is almost a straight drop-in replacement for R134a. The molecule is similar to R-134a except that two hydrogen atoms are substituted for two fluorine atoms. It has similar operating characteristics to R-134a but cools even better. An environmental benefit of HFC-152a is a working fluid which has a global warming rating of 120, which is 10 times less than R-134a, but still a lot higher than CO2. That is why HFC-152a is currently used in many aerosol products as a propellant. Its main drawback is that it is slightly flammable. C.HFO-1234yf Another new refrigerant which is being considered is HFO1234yf and developed jointly by Honeywell and DuPont; it is being promoted as a possible drop-in replacement for R134a in both new vehicles and older vehicles, should that become necessary in the future. HFO-1234yf has thermal characteristics that are very close match to R134a, there is no major modifications to the A/C system. Better yet, HFO-1234yf has a global warming potential of only 4, compared to 1200 for R-134a, allowing it to meet the European requirements for a GWP of less than 150. D. Ammonia Ammonia is produced in a natural way by human beings and animals; 17 grams/day for humans. Its ODP and GWP both are zero and posses excellent thermodynamic characteristics: small molecular mass, large latent heat, large density and excellent heat transfer characteristics .Its smell causes leaks to be detected and fixed before reaching dangerous concentration also available at relatively low price. The only drawback of NH3 is that it is toxic, flammable and not compatible with copper. E.134a R 134a is a HC-based refrigerant and which is a blend of environmentally harmless hydrocarbon fluids designed as a direct replacement and retrofit with refrigerant option for replacing R123a and R12 refrigerants in automotive air conditioning and refrigeration systems outside of the US.. Super-freeze 134a operates at lower head pressures and offers improved cooling properties and performance. V. APPLICATIONS OF REFRIGERANTS F. Domestic refrigeration The vast majority of domestic refrigerators use R134a, which is a relatively close match for R-12. Disadvantages of R-134a include relatively poor performance at low evaporating temperatures compared to R-12 and a requirement to use synthetic lubricants like Polyol ester. Hydrocarbons took over from R-134a for domestic refrigerators in certain parts of the world. The most commonly used hydrocarbon is butane (R600) and isobutene (R-600a) are, at first sight, a astonishing choice because of the large volumetric flow required but the high critical temperature, 135 oC, and low cycle pressures combine to produce a very quiet and efficient system. The safety testimony has been excellent. G. Automotive air conditioning The dominant refrigerant for car air conditioning is R-134a. Emissions to atmosphere from this source are causing concern. H. Commercial refrigeration The dominant refrigerants in this field were R-22 and R-502. Zero ODP replacements for these substances tend to be blends of several HFC refrigerants, including R-32, R-125, R-143a, R152a, R-134a, sometimes with the addition of a hydrocarbon to improve transport of lubricant within the system. Replacement blends in the 400 and 500 series have performed relatively well in filling the gap left by R-22 and R-502 but serious concern is being expressed about their high global warming potentials and their low critical temperatures. More efficient substitutes are being sought but the availability of substances to replace the methane and ethane type HFCs is limited. They have been some use of hydrocarbons in the commercial refrigeration industry but the practice is not widespread. I. Air conditioning Air conditioning has come to be almost completely carried out using halocarbon refrigerants. R-134a is used for small, fully sealed, systems and for centrifugal systems. R-404A and R-407C are the most commonly used refrigerants for larger systems. R-404A has very little glide but operates at higher pressures than R-22 and has lower theoretical efficiency at extreme pressure ratios. Vol. 5 Issue 2 March 2015 450 ISSN: 2278-621X International Journal of Latest Trends in Engineering and Technology (IJLTET) J. Industrial refrigeration Ammonia continued to be used in the more traditional sections of the industrial refrigeration industry, though its use declined significantly with the advent of the non-toxic, non-flammable halocarbons. Two unrelated events reversed the tendency away from ammonia. The first was the emergence of the oil-cooled screw compressor, which overcomes the high discharge temperature problems which have to be countered when using reciprocating compressors with ammonia. The second was the publication of their ozone depletion theory by Roland and Molina. Use of ammonia has been increasing in recent years and the use of ammonia is extending back down into regions which, in the past, would have been served by reciprocating compressors using halocarbon refrigerants. K. Halocarbons Halocarbons are so convenient to use that a strong case can be made for their continuing use. However, better methods of containment are essential and more efficient refrigerants with higher critical temperatures and lower GWPs should be sought. It is clear that most losses of refrigerant come from "serviceable" systems, such as car air conditioning, and from distributed and serviceable systems, such as supermarket installations. By contrast, refrigerant loss from fully sealed, factory-constructed systems, such as domestic refrigerators and window air conditioners, is much less. The charge of such systems is also small. As previously indicated, there are few possible compounds available which are not halocarbons.SF6 would have some potential as a refrigerant but it has a very high GWP of 22,200.HFE are theoretically possible but they too have high GWPs. E-125 (CHF2-O-CF3) has an ideal boiling point of –42oC but is prohibitively expensive to produce and has a GWP of 15 300. I’ve long been an advocate of the use of R-218 (C3F8) because it forms a zoetrope with a large number of halocarbons and therefore allows the production of a wide variety of potentially efficient blends. The GWP of R-218 is 7000 but, as far as I am aware, it has not been detected in the atmosphere despite being used in some industrial processes for many years. Table 1. Currently used Zero ODP Refrigerants Refrigerant Formula NBP0C Glide K T c (0C) GWP R-134a R-413A R-404A R-507A R-407C R-417A R-410A R-508 R-717 R-600a R-290 R-1270 CH2F.CF3 R- 134a.218/600a R-143a/125/134a R-143a/125 R-32/125/134a R-125/134a/600 R-32/125 R-23/116 NH3 CH (CH3)3 C3H6 C3H6 -26 -35 -47 -47 -44 -43 -51 -86 -33 -12 -42 -48 0.0 6.9 0.7 0.0 7.4 5.6 0.2 0.0 0.0 0.0 0.0 0.0 101 101 73 72 87 90 72 13 133 135 97 92 1300 1900 3800 3900 1700 2200 2000 12000 0 20 20 20 Safety Group A1 A1/A2 A1/A1 A1 A1/A1 A1/A1 A1/A1 A1 B2 A3 A3 A3 Table 2. Possible Future Blend Components Refrigerant Formula NBP (oC) CT (o C) ODP GWP R-23 R-32 R143a R-161 R-218 R-134a R-227ea R-236fa R-143 R-245fa R125 CHF3 CH2F2 CH3.CF3 CH3.CHF2 C3F8 CH2F.CF3 CF3.CHF.CF3 CF3.CH2.CF3 CH2F.CHF2 CHF2.CHF.CHF2 CHF2.CF3 -81.2 -51.7 -47.2 -37.2 -36.6 -36.6 -15.6 -1.4 5.0 15.1 -48.1 25.9 78.2 72.9 102.2 71.9 101.1 102.8 124.9 156.6 154.1 66.2 0 0 0 0 0 0 0 0 0 0 0 12000 550 4300 12 8600 1300 3500 9400 300 950 3400 Vol. 5 Issue 2 March 2015 451 ISSN: 2278-621X International Journal of Latest Trends in Engineering and Technology (IJLTET) V. CONCLUSION People are at a time of transition in refrigeration. Such times are always interesting but some accasion painful and dangerous. It is a time of challenge the changes of refrigerants .and opportunity for professional young researchers. Ammonia, Hydrocarbons and Carbon dioxide that may lead to zero ODP and minimal GWP. For making the refrigerant more efficient system need to have low TEWI factor. In the future, the development agents will further develop more refrigerants which will not only be making the work system more efficient but also having the eco-friendly nature, leading to the accomplishment of the refrigeration goals and enhancing the wellbeing and safety of the worker. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] three Ozone- Friends HFC Refrigerants in a Refrigerator Journal of Sustainable Energy &Environment 2 (2011) 61-64. T.O. Palade, Comparative analysis of performance of three ozone-friends HFC refrigerants in a compression refrigerator, Journal of Sustainable Energy and Environment 2 (2011) 61-64. S. Wong wises, A performance of compression refrigeration system using various alternative refrigerants, International Communication in Heat and Mass Transfer 37 (2010) 1340-1349. Bagola O. Baoji, Exegetic performance of a domestic refrigerator using R12 and its alternative refrigerants, Journal of Engineering Science and Technology, Vol. 5, No. 4 (2010) 435-446. Wong wises, Nares Chimers, Experimental study of hydrocarbon mixtures to replace HFC-134a in a domestic refrigerator, Energy Conversion and Management 46 (2005) 85-100. Tiwari, R.C. Gupta, Recent developments on domestic refrigerator-a review, International Journal of Engineering Science and Technology, Vol. 3, No. 5(2011) 4233-4239. Agrawal R S (2001) Montreal protocol on refrigeration and air conditioning industry. Proc. of Int. conf. on emerging technologies in airconditioning and refrigeration, New Delhi, India, Sept 26-28. Pp13-25. Zhejiang Liu, Imam Haiden, B.Y. Liu, Reinhardt Test Results of Hydrocarbon Mixtures in Domestic Refrigerator freezers Center for Environmental Energy Engineering (CEEE) University of Maryland College Park, Maryland, USA. Agrawal and Vidin Srivastava, Retrofitting of compression refrigeration trainer by an ec0-friendly refrigerant, Indian Journal of Science and Technology, Vol. 3, No. 4 (2010) 455458. S. Wong wises A performance comparison of compression refrigeration system using various alternative refrigerants. International Communications in Heat and Mass Transfer 37 (2010) 1340–1349. Zhou X, Lien Z, Li Z, Yao Y, Experimental study on HFC125 critical heat pump, Applied Thermal Engineering 27 (2009) 988-993. [13] ASHRAE, Thermo physical Properties of Refrigerants Chapter 20, ASHRAE Fundamental, Inc. Atlanta 20 (2001) 1-67. Biter, Refrigerant Report, Blitzer International, 13th Edition, 71065 Sindelfingen, Germany, http://www.bitzer.de Accessed on June 24, 2007. Johnson 1998, Global warming from HFC, environment impact assessment rev, 18, 485 – 492. Zhou X, Lien Z, Li Z, Yao Y, Experimental study on HFC125 critical heat pump, Applied Thermal Engineering 27 (2009) 988-993. R. Cabello, J. Navarro-Esbri, Experimental evaluation of a compression plant performance using R134a, RR407C and R22 as working fluids, Applied Thermal Engineering 24 (2004) 1905-1917. K. Raja opal, Computational and experimental investigation of low ODP and low GWP HCFC-123 and HC-290 refrigerant mixture alternative to CFC-12, Energy Conversion and Management 48 (2007) 3053-3062. Calm, J.M., The next generation of refrigerants Historical review, considerations and outlook. International Journal of refrigeration, 31: 11231133. DOI: 10.1016/j.ijrefrig.2008.01.013. Bryan Chambers, 16 April 2009. Introduction of Vapor Compression Refrigeration Cycle. T.O. Palade, Comparative analysis of performance of three ozone-friends HFC refrigerants in a compression refrigerator, Journal of Sustainable Energy and Environment 2 (2011) 61-64. Wendy, 2005, An over view of environmental hazards and exposure and explosive rise of HFCs, chemosphere, 61, 1539-47. Vol. 5 Issue 2 March 2015 452 ISSN: 2278-621X

© Copyright 2026