Using copper sulphate to control snails

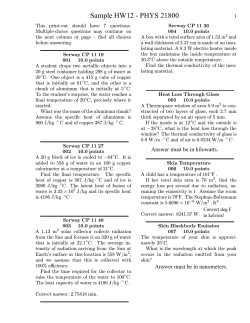

Managing rice snails with copper sulphate Mark Stevens1 & Greg Doran 2 NSW Department of Primary Industries, Yanco Agricultural Institute School of Agricultural and Wine Sciences, Charles Sturt University, Wagga Wagga 1 2 QUICK TAKE ›› Snails in rice crops are becoming a more significant problem for growers because of increased levels of repeat cropping aimed at maximising water use efficiency. Repeat cropping allows dormant snails to survive in the soil. ›› Research on copper sulphate aimed at gaining product registration and ensuring its ongoing availability for snail control has shown that its variable performance relates strongly to soil type. Higher application rates are needed to the water above soils rich in dissolved organic carbon. ›› Even above soils low in dissolved organic carbon, biologically active copper concentrations fall dramatically within an hour of application. ›› Although soil testing could allow copper application rates to be ‘fine-tuned’ for individual fields, finding alternative chemicals Snails in rice crops can be effectively managed through crop rotations, however this conflicts with the need for farmers to minimise total farm water use by using water remaining in the soil profile from the previous crop. Chemical control is the only other option for snail control, and copper sulphate is the only chemical currently available. Although generally effective, its behaviour in the environment means its use has several drawbacks. Crop rotation practices play a significant role in the extent of snail problems in rice crops. Research has shown that when crops are drained prior to harvest a proportion of snails enter dormancy in the top layers of the soil, and survival through to flooding of the next crop in spring can be around 45%. Dormant snails cannot survive the additional 12-month period if a summer fallow is used, and consequently breaking the cropping cycle has been an effective method of reducing snail problems during crop establishment. Rice crop rotations come at a price, however. Repeat crops use approximately 10% less water than crops on ‘new’ ground because water remaining in the soil profile reduces the amount of water required for initial bay filling. The need to conserve water has led to increased repeat cropping and consequent increases in snail problems. Copper sulphate has been the only chemical used against snails in rice since they first became a major problem in the mid-1970s. Its use was legitimised under a number of APVMA permits, however around 2006 the APVMA indicated that no further permits would be issued and that they required copper sulphate to be registered. This necessitated research on the efficacy and environmental fate of copper in rice fields, and copper sulphate gained formal registration prior to the 2012–13 rice season. The results of this work have helped us understand why copper performance can be so variable between different areas. Field trials Trials conducted at Yanco using snails in stainless steel enclosures proved that copper is effective against adult snails, with conditions at our trial site requiring around 6.4 kg/ha of copper sulphate pentahydrate for 95% snail mortality. This is at the lower end of the 6–12 kg/ha rate range that has been in use for many years. Of particular interest was the rate at which dissolved copper concentrations declined in the water in the rice field, as only free ionic copper has significant activity against snails. unaffected by soil type should be a higher priority. The native snail Isidorella newcombi is responsible for over 95% of damaging rice crop infestations. IREC Farmers’ Newsletter – Large Area No. 189: Spring 2013 15 snails in rice sediment copper concentration (mg/kg) 30 Whilst total copper (dissolved and bound to particulate matter in the water column) fell by an average of 13.7% in the first hour after application, the corresponding fall in dissolved copper was much larger at 46.2%. Of the dissolved copper that remained only a proportion would be ionic copper with activity against snails; the remainder would have been bound up with dissolved organic carbon compounds. 28 26 24 22 One of the major drawbacks of copper is that it remains in an active form for only a very limited time, necessitating a high application rate to expose snails to a lethal dose in a very short time frame. 20 18 So where does the copper go? 16 14 12 0 2 4 6 8 Figure 1 shows the copper concentrations in sediment samples from the bottom of our trial bays 30 days after copper application. Trial 1 Trial 2 r 2 = 0.91 10 12 copper sulphate applied (kg/ha) Figure 1. Effect of copper sulphate application on sediment copper concentrations 30 days after treatment. dissolved copper (mg/L ±SE) 1.0 Murrami Yanco Leeton 0.8 Factors affecting site to site variability To examine how local conditions might be affecting the performance of copper against snails, we collected three soils from Yanco, Leeton and Murrami, and used them in soil/water systems to bioassay rice snails against copper. 0.6 0.4 We found that approximately twice as much copper was needed to kill 90% of the test snails above the Murrami soil than above the other two soils. 0.2 0.0 0.1 1.0 10.0 100.0 hours since addition (log scale) Figure 2. Dissolved copper in the water column of soil/water systems involving three different test soils. Starting copper concentration 0.8 mg/L, irrigation water. 250 snail LC90 soil DOC overlying water DOC 200 Initially, we thought that the dissolved copper might be adsorbing to the soil surface. To test this we set up large numbers of soil/water systems, treated them with copper, and measured the dissolved copper concentrations over time. Our results are shown in Figure 2, and were essentially the opposite of what we expected—more copper was remaining in solution above the Murrami soil than above the other soils, so losses due to adsorption to the soil surface were not the answer. The copper remained in the water column, but its toxic effect was somehow being neutralised. None of the measured soil or water parameters such as pH, clay content or water hardness correlated with our toxicology results, so we looked at dissolved organic carbon (DOC). Analyses of the soil, and also of the water in the soil/water systems at the time the snail bioassays were conducted showed that variable levels of dissolved organic carbon in the soil are almost certainly the main cause of variable copper performance across different sites. units 150 100 50 0 There is a strong linear relationship between the amount of applied copper and the subsequent sediment copper concentration—at the high end of the scale, an application of 12 kg/ha of copper sulphate has almost doubled the sediment concentration from a baseline concentration of 15 mg/kg to about 28 mg/kg. On average, only 22% of applied copper was recovered from the sediments 30 days after treatment, however all applied copper not removed at trace levels in the crop will ultimately find its way into the soil. In the longer term this has the potential to cause sustainability issues. Murrami Leeton Yanco Figure 3 shows the toxicology results combined with the dissolved organic carbon levels of the soil and water. The Murrami soil contained around three times as much extractable dissolved organic carbon as either the Leeton or Yanco soils, and three days after inundation of the soil/water systems, the dissolved organic carbon levels in the water were twice as high above the Murrami soil relative to the other two test soils. soil type Figure 3. Relationship between the amount of copper necessary to kill 90% of test snails (LC90), soil dissolved organic carbon (DOC), and DOC in the overlying water of soil/water systems. 16 IREC Farmers’ Newsletter – Large Area No. 189: Spring 2013 snails in rice Insights into copper behaviour Aside from facilitating the registration of copper sulphate and ensuring its ongoing availability to rice growers, this project has provided insights into how copper behaves in the rice field environment. Copper applied to control water snails remains active for only a very short period of time, and ultimately ends up in the soil. Adsorption to the soil surface appears not to be the main factor affecting copper efficacy. Rather, leaching of dissolved organic carbon into the water column from the underlying soil is apparently a key factor, and leads to the copper losing its biological activity whilst still in the water column. Crops grown on soils high in dissolved organic carbon will require copper application rates at the higher end of the 6–12 kg/ha allowable rate range to compensate for this effect. Although soil dissolved organic carbon is clearly important, dissolved organic carbon and hardness levels in source water are also likely to have a role in mitigating copper toxicity. Although it is difficult to generalise, darker soils rich in organic matter are likely to be more problematic when snail control is attempted with copper sulphate. With further research it may be feasible to develop a model that, along with soil testing, would allow growers to optimise the copper sulphate application rate within the registered range for individual paddocks, however this would not overcome the underlying problems associated with copper sulphate, including its limited persistence in a biologically active form even when used above soils low in dissolved organic carbon, its lack of effectiveness against snail eggs, and its capacity to accumulate in soils. Identifying and commercialising alternative snail control chemicals should continue to be a high priority. RIRDC Project PRJ-005685 Further information Mark Stevens T: 02 6951 2644 M: 0477 047 216 E: [email protected] Simple soil/water systems were used to determine how snails respond to applied copper above different soils, and to gain an understanding of how soil type affects copper toxicity. IREC Farmers’ Newsletter – Large Area No. 189: Spring 2013 17

© Copyright 2026