Innovative total station training for Ironworkers launches in California

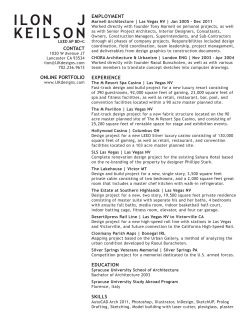

Innovative total station training for Ironworkers launches in California Many jobs these days demand new skills. It’s no longer enough for firefighters to just fight fires. And it’s no longer enough for ironworkers to just tie rod and weld. “We want ironworkers to be involved in all phases of work, and that is why we’re training as many as we can in the skills to operate a total station,” says Mike Silvey, business manager of Ironworkers Local 433 in Los Angeles and Las Vegas. Jason Corder, apprenticeship coordinator at Ironworkers Local 416/433 training center in Las Vegas, teaches total station instrumentation throughout California. A total station is a surveying instrument that combines the functions of a theodolite, also known as a transit, and an electronic distance meter. It is used by land surveyors, civil engineers and crime scene investigators. Total station instruments are increasingly being used on job sites as the highest form of construction layout as more jobs rely on Building Information Modeling, digital plans that make available the coordinates of every beam, pipe, conduit and duct. Ironworkers and their contractors recognize the need for the training so that they continue providing the highest quality workmanship and skills on the job site to the benefit of project owners, says Silvey, an early advocate for total station training within the International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers. Other advocates for the training were from the Ironworker Management Progressive Action Cooperative Trust (IMPACT), including Rick Sullivan, director of education and training, and instructors Gene Matthews, Russ Gschwind, as well as Keith Lantz of Leica Geosystems. The new program is an asset to contractors, says instructor Jason Corder, apprenticeship coordinator at the Ironworkers Local 416/433 training center in Las Vegas. He is traveling to University of Iron campuses around California to teach the 40-hour course to experienced journeymen with a firm grasp of mathematics, including trigonometry. “Through this program, our contractors will have a team in place with the ability to check the layout of other trades and find layout issues before work begins,” says Corder. The high-tech instrument is a major time-saver in erecting steel and curtain-wall systems, says Silvey. For example, when doing the layout of a curved wall with 15 segments using a transit, measurements must be taken from 15 points. Using a total station allows the measurements to be taken from a single center point, he says. As building designs become more complex, the time savings increase. And, as Silvey notes, “architects are not keeping the buildings square anymore.” Says Silvey: “It’s my opinion that total station instruments are going to be the same thing in the field as computers are in the office.”

© Copyright 2026