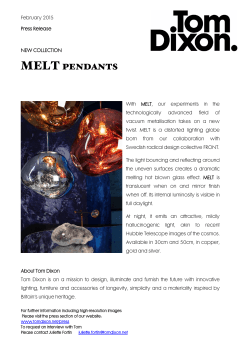

PhD_Thesis_Sachin_Thakre