SEPARATION METHODS

SEPARATION METHODS

Objectives

• Explain the role of separations

operations in industrial chemical

process

• Explain what constitutes the separation

of a chemical mixture and enumerates

general separation techniques

• Explain the use of external fields to

separate chemical mixtures

Introduction

• Early civilization techniques:

– - Extracts metal from ores

– - Perfume from flower

– - Dyes from plant

– - Evaporation of sea water to obtain salt

– - Distill liquor

Introduction

• Chemist – use chromatography to

separate complex mixtures quantitatively

• Chemical engineers – concerned with

the manufacture of chemicals using large

scale separation methods

Chemical Processes

• Conducted:

– Batchwise

– Continuous

– Semi-continuous

Key operations in chemical process

involved:

- Reaction Processes

- Separation Processes

Mechanism of Separation

• Mixture of homogenous phase

• Mixture of two or more immiscible

phases

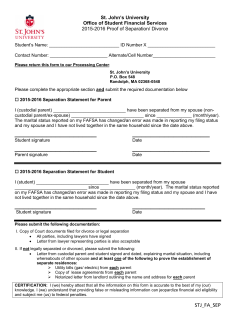

MEMBRANE

PERMEATE

HYDROGEN

Light

Hydrocarbons

RESIDUE

Sieve

Dryer

Feed

FURNAC

E

COOLING

Caustic Scrubber

LIQUIDS

EXAMPLE: SEPARATION PROCESS

Heavier

Hydrocarbons

Mechanism of Separation

• Mixing of chemical is spontaneous,

increase entropy and randomness.

• Separation of chemicals requires the uses

of energy.

• Separation includes:

– - Separation of component A from mixture in

homogenous phase

– - Separation of component A from mixture in

different phases

Mechanism of Separation

• If two or more immiscible phases exist

mechanical separation is preferable

• E.g: Centrifuge, pressure reduction,

electric/magnetic field

Basic of separation

Types of Separation Process

1) Separation

creation

2) Separation

3) Separation

4) Separation

by phase addition or

of barrier

by solid agent

by external field or gradient

- Centrifugation

- Thermal diffusion

- Electrophoresis

- Electrodialysis

Phase creation process

• Involve the creation of a second phase

that is immiscible with the feed.

• Accomplished by energy or pressure

reduction.

• Suitable for mixture that have tendency

to vaporize.

• E.g: Evaporation, sublimation,

crystallization, distillation.

Phase addition processes

• For separation of homogenous, single phase

mixture, a second immiscible phase must be

developed.

• This is achieved by:

– - Creation of energy separating agent (ESA)

– - Mass separating agent (MSA)

• When 2 immiscible fluid phases are contacted,

intimate mixing of the 2 phases is important in

enhancing mass transfer rates.

• After phase contact, employing gravity and/or

enhanced techniques completed the

separation process.

Cont’

• Disadvantages of MSA:

- Need additional separator to recover

MSA

- Need for MSA make up

- Possible contamination of the product

- More difficult design procedure

• Eg: Extractive distillation, liquid-liquid

extraction, leaching

Separation by Barrier

• Includes the use of microporous and

nonporous membrane as semipermeable

barriers

• Membrane are fabricated from polymer,

natural fiber, ceramic, metal etc.

• Microporous membrane – separation occur

at different diffusion rate

• Nonporous – separation based on the

solubility

Cont’

Hydrogen removal in refineries, ammonia plants, and olefin

units.

Separation by Solid Agent

• Process that use solid mass-separating

agents.

• Solid normally in the form of a granular

material or packing. E.g: activated

carbon, aliminium oxide, silica gel, or

calcium aluminosilicate zeolite.

• Example of process: Adsorption,

Chromatography, & Ion Exchange.

Generalized downstream

processing

Bioseparation

Techniques

RIPP Scheme

• Liquid-solids separations (dewatering,

concentration, particle removing) @

Recovery

• Solute-solute separations (Isolation,

Purification)

• Solute-liquid separations (Polishing)

Bioseparation Techniques

Stage

Objective(s)

Recovery

• Remove or collect cells,

(separation of cell debris

insolubles)

• Reduce volume

Typical Unit

Operations

Filtration, sedimentation,

extraction, adsorption,

centrifugation

Isolation

• Remove materials having Extraction, adsorption,

properties widely different ultrafiltration,

from those of target

precipitation

product

• Reduce volume

Purification

• Remove remaining

impurities, which typically

are similar to those of

target product

Chromatography, affinity

methods, precipitation

Polishing

• Remove liquids

• Convert product to

crystalline form (not

always possible)

Drying, crystallization

Example of bioseparation

Separation and purification of intracellular

enzymes

fermentation

lyophilization

Cell removal and

concentration

Cell disruption

Removal of cell

debris

Protein

precipitation or

aqueous twophase extraction

dialysis

Solvent

precipitation

Chromatographic

purification

ultrafiltration

Rules of thumb

• Remove the most plentiful impurities first

• Remove the easiest-to-remove impurities

first

• Make the most difficult and expensive

separations last

• Select processes that make use of the

greatest differences in the properties of

the product and its impurities

• Select and sequence processes that

exploit different separation driving forces

Cyclodextrin

Remove the easiest-to-remove

impurities first: unused starch, linear

Remove the most plentifuldextrins,

impurities

glucose, maltose, etc

first: CD-agent complex

Select processes that make use of the

greatest differences in the properties of the

product and its impurities: decanol and CD

Make the most difficult and

expensive separations last:

CD crystals

Select and sequence processes

that exploit different separation

driving forces

Example 1

You have been given a task to purify the erythromycin antibiotic

from fermentation broth. The information on erythromycin is given

below. What do you think the most likely unit operations that

should be used for the isolation and purification of

erythromycin? Justify the reasons for the selection of the unit

operations.

Information on erythromycin

Formula

: C37H67NO13, Molecular weight

: 733.94

Form

: Salts with acids, Melting point : 56 °C

UV max

: 280 nm, pKa

: pH 8.8

Freely soluble in alcohols, acetone, chloroform, acetonitrile,

ethyl acetate. Moderately soluble in ether, ethylene

dichloride, amyl acetate. Hydrated crystals from water,

melting point 135-140 °C. Resolidifies with second melting

point 190-193 °C

Solution

Erthromycin has limited solubility in water but is

soluble in several solvents, including amyl

acetate. Since the solubility of amyl acetate is

low, isolation could be performed by a liquid-liquid

extraction of erythromycin using water-amyl

acetate system. For the extraction, it would be

desirable to raise the pH of the aqueous phase above

the pKa of erythromycin of 8.8, so that the secondary

amino group is converted from the positively charged

from the neutral free base form. For the purification step,

crystallization is a good choice, since hydrated crystals

have been obtained from water.

g{tÇ~ çÉâ‹AA

© Copyright 2026