Dominant selection - Mejeriteknisk Selskab

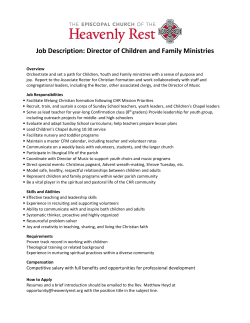

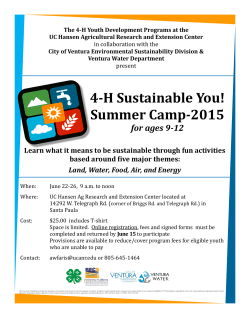

Naturlige strategier til forbedring af industrielle mælkesyrebakterier Kim I. Sørensen Senior Principal Scientist Bacterial physiology and improvement, Discovery Chr. Hansen A/S _ Copyright © 2014 Chr. Hansen A/S. All rights reserved New Product Development for the DAIRY Industry Finding & Improving Lactic Acid Bacteria Taste Texture Yield Shelf life Health benefits Add in Take out Sugar, Fat, Protein Texturizers Stabilizers Preservatives Copyright © 2015 Chr. Hansen A/S. All rights reserved Chr. Hansen’s Strain Discovery platform Combining LEAN principles and a State of the Art Automation & –Omics platform* A platform designed to find and improve novel bacterial functionalities 2- Classical Strain Improvement Non-GMO Two approaches: High Throughput Screening Dominant Selection Strain Supply Chain 1- Natural Diversity Wild type/natural isolates Chr. Hansen Culture Collection Robotized semi-automated setup for characterization * Johansen et al. in Advances in fermented food and beverages. 2013. Copyright © 2015 Chr. Hansen A/S. All rights reserved. Diversity Screening of Lactic Acid Bacteria Chr. Hansen Culture Collection - CHCC Genera-sorted MTP screening collection Chr. Hansen strains depository > 20.000 deposits Worldwide origin Sourcing in compliance with Convention on Biological Diversity/Rio (1992) Lactococcus Streptococcus Lactobacillus …………… >70% of species in CHCC = Lactic Acid Bacteria Brevi 1% Bifido 5% Propioni 1% Others 17% Bacillus 4% Single strain deposits (individually purified) >25% of CHCC deposits available in MTP 96-Well MTP for fast retrieval and automation Robotics to automate characterization Datasets for each individual strain from >40 assays Enabling fast new product development Enterococcus 2% Streptococcus 15% Oenococcus 2% Leuconostoc 3% Lactobacillus 28% Lactococcus 22% Copyright © 2015 Chr. Hansen A/S. All rights reserved Primary characterization of strains Assay portfolio Primary characterization Assay 1 Species identification 16S sequencing Growth M17/MRS + different C-sources Fermentation media – upscaling Temperature (30, 37, 40 & 43 ºC) O2 tolerance Bile / acid stress Acidification speed Milk acidification in microtiter plates (100 to 2000 ul) Assay 2 Salt Tolerance (0 vs. 4% NaCl) Antibiotic resistance Database Erythromycin (2 µg/ml) Tetracycline (2, 4, 8, 16 & 32 µg/ml) Metabolite fingerprinting (typically milk) Volatile Organic Compounds Assay 3 Phage-HTS profiling Milk acidification in microtiter plates Mitomycin induction (prophage) Enzymatic activities Urease Arginine deiminase Peptidases (& proteinases) Assay 4 Bacteriocin screen Stress tolerance Temp, pH, EtOH, SO32-, … Copyright © 2015 Chr. Hansen A/S. All rights reserved. Automated Characterization of LAB Collections Assay Development - Acidification Acidification - Color of pH MTP based method to measure pH in acidified milk* Bromocresol based pH indicators Measure “color” (hue angle) in flatbed scanner Clustering of >800 Lactococci Clustering of >800 unique Lactococci based on their ability to acidify milk under different conditions** Fast grouping, visualization and selection of strain leads Phenotypic overlays based on primary screening data (species ID, antibiotic resistance profiles & bacteriophage sensitivity, enzymatic activitities a.o.) *: Houlberg et al. (2007) WO 2005/068982 **: Johansen et al. (2014) in Advances in fermented food and beverages: In Press Copyright © 2015 Chr. Hansen A/S. All rights reserved New Product Development for the DAIRY Industry Finding & Improving Lactic Acid Bacteria Example 1-Screening Taste Texture Yield Shelf life Health benefits Add in Take out Sugar, Fat, Protein Texturizers Stabilizers Preservatives Copyright © 2015 Chr. Hansen A/S. All rights reserved The needle in the Haystack Lb. rhamnosus - Giving low-fat yoghurts a good taste - Low-fat yoghurt are healthy Customers want low-fat, clean label & good taste Screening of >250 Lactobacilli for the ability to produce Acetaldehyde & Diacetyl/Acetoin to improve “fat perception” in low-fat yoghurts One new strain identified: Lactobacillus rhamnosus Diacetyl (Acetoin) Acetaldehyde Temperature range 35-43ºC Jiminez et al. patent WO2012/136832 Copyright © 2015 Chr. Hansen A/S. All rights reserved. New Product Development for the DAIRY Industry Finding & Improving Lactic Acid Bacteria Example 2-Screening Taste Texture Yield Shelf life Health benefits Add in Take out Sugar, Fat, Protein Texturizers Stabilizers Preservatives Copyright © 2015 Chr. Hansen A/S. All rights reserved An Example How some of the most effective bioprotective strains were selected. Searching in the Chr. Hansen strain collection for LAB candidates 200 strains 55 Target contaminants isolated from Russian Tvarog (fresh cheese) + library of spoilage yeasts and molds Screening of multiple combinations in laboratory assays imitating conditions in the final application Challenge tests 17 Secondary characterization 10 Copyright © 2015 Chr. Hansen A/S. All rights reserved. Secondary characterization Packages of six strains selected from primary characterization showing the selected properties for the future product FreshQ Question: do they resemble one another or strains already in production? 11 100 80 60 Answer Yes or NO via DNA fingerprint comparison PFGE1-AscI . Lactobacillus paracasei L. casei 01 . Lactobacillus paracasei PDA10058 . Lactobacillus paracasei LBAca-14676 – the canidate is OK . Lactobacillus paracasei CRL-431 . Lactobacillus paracasei PDA10066 . Lactobacillus paracasei LBAca-3808 . Lactobacillus paracasei Contract strain FreshQ® cultures Currently available: F-DVS FreshQ®1 developed primarily for mesophilic applications FD-DVS FreshQ®2 and 4 developed primarily for thermophilic applications The strains used in FreshQ® are from the species L. rhamnosus and L. paracasei and both species are Qualified Presumed as Safe (QPS) by EU EFSA and have been tested to confirm that they do not produce unwanted metabolites or harbor any acquired antimicrobial resistance genes Copyright © 2015 Chr. Hansen A/S. All rights reserved. Different molds are strongly inhibition by FreshQ®1 - 18% sour cream Ref. Inhibition after 45 days storage: Top two rows: 7ºC/45ºF Bottom rows: 12ºC/54ºF FreshQ®1 Challenge moulds: • • • • • • Ref. 208: 216: 151: 329: 416: 214: P. crustosum P. glabrum P. brevicompactum P. commune P. solitum A. versicolor Contamination level: 1000 spores/spot, The contamination level is substantially higher than normal industrial contamination. FreshQ®1 208 216 151 329 416 214 Copyright © 2015 Chr. Hansen A/S. All rights reserved. Mold inhibition of FreshQ® in sour cream Challenge test on sour cream produced at Chr. Hansen (6% fat; 0.01% DSG-200070) Reference Benchmark 30 days at 7°C FreshQ 2 FreshQ 1 P. Commune A. versicolorP. Brevicompactum P. crustosum P. glabrum 14 Copyright © 2015 Chr. Hansen A/S. All rights reserved. Chr. Hansen’s Strain Discovery platform Combining LEAN principles and a State of the Art Automation & –Omics platform* A platform designed to find and improve novel bacterial functionalities 2- Classical Strain Improvement Non-GMO Two approaches: High Throughput Screening Dominant Selection (Work Smart) Strain Supply Chain 1- Natural Diversity Wild type/natural isolates Chr. Hansen Culture Collection Robotized semi-automated setup for characterization * Johansen et al. in Advances in fermented food and beverages. 2013. Copyright © 2015 Chr. Hansen A/S. All rights reserved. New Product Development for the DAIRY Industry Finding & Improving Lactic Acid Bacteria Example 1- Selection Taste Texture Yield Shelf life Health benefits Add in Take out Sugar, Fat, Protein Texturizers Stabilizers Preservatives Copyright © 2015 Chr. Hansen A/S. All rights reserved Automated Characterization of LAB Collections Assay Development - Texture Texture – HTS Pressure (Pa) Texture is a key parameter for fermented milks Development of a texture screening method based on back-pressure measurement during pipeting /96 channels Back pressure measurement of fermented milks correlates to conventional rheology/shear stress measurements (R2 = 0,92) Time (mS) Fast & accurate deepwell-MTP based method to determine texturizing properties of LAB collections and mutant pools Proof of Concept: Characterization of >800 unique Lactococci for their ability to acidify & texturize milk* *: Kuzina-Poulsen et al. (2014) EP14182194; Poster LAB11 Copyright © 2015 Chr. Hansen A/S. All rights reserved Toolbox – selection: Texture improvement • Galactose prototrophy – Dominant selection • Texturizing lactic acid bacteria strains by selection of lactic acid bacteria resistant towards D-cycloserine and/or functionally equivalent antibiotics(WO 2012052557 A1) • Lactic bacterium for texturizing food products selected on basis of phage resistance (Patent Application WO/2011/092300) Improving texture in yoghurt: Selection Direct selection for mutants able to grow on galactose as sole carbon source Gal-medium S. thermophilus 6008 Galactose prototrophy – Dominant selection Yomax (CHCC11379) Improved shear stress Galactokinase (galK) promoter mutation in CHCC11379 galK twofold up-regulated 20% reduction in galactose content in milk after 6h fermentation 19 Copyright © 2013 Chr. Hansen A/S. All rights reserved. Christiansen and Janzen EP 2473058 A1 Copyright © 2015 Chr. Hansen A/S. All rights reserved. Chr. Hansen’s Strain Discovery Platform Combining Lean Principles and a State of the Art Automation & –Omics Platform* Example 2- Selection A platform designed to find and improve novel bacterial functionalities 1- Natural Diversity Wild type/natural isolates Chr. Hansen Culture Collection Robotized semi-automated setup for characterization Taste Texture Yield Shelf life Health benefits 2- Classical Strain Improvement Non-GMO Three approaches: Random mutagenesis Directed Evolution Dominant Selection Take out Add in Sugar, Fat, Protein.. Texturizers, Stabilizers Preservatives SWEETY™ Copyright © 2015 Chr. Hansen A/S. All rights reserved Classical Strain Improvement Applied - Sweety The Challenge Yoghurt is considered a healthy natural product; but often contains added sucrose to boost sweetness The Concept Enhancing the natural sweetness of yoghurt by designing LAB mutants which, without the use of recombinant DNA technology, excrete glucose & metabolize galactose instead Pool et al. (2006): Lactococcus lactis** Not appropriate for yoghurt production Use of recombinant DNA technology to make strains unable to grow on glucose Not all sugars are perceived equal, at least with regard to sweetness *: *: Robyt (1998) Sweetness, in Essentials of carbohydrate chemistry, Springer-Verlag, New York **: Pool et al. (2006) Metab. Eng. Copyright © 2015 Chr. Hansen A/S. All rights reserved The Approach: A Multi Step CSI Process * S. thermophilus Step 1: Growth on Galactose Yoghurt starter cultures typically contain 90% S. thermophilus and 10% Lb. delbrueckii subsp. bulgaricus S. thermophilus grown on lactose, metabolize glucose and excrete galactose ** Enabling & boosting the fermentation of galactose by S. thermophilus***: Dominant selection using galactose as sole carbon source G to A mutation at -10 position in the galK promoter results in a 2.5 to 3.7 fold increase of transcription of the genes in the galactose operon (galK, galT, galE, and galM) *: Johansen et al. (2013) WO 2013/160413A1 **: Adapted from Hols et al. (2005) FEMS Microbiol Rev ***: Janzen & Christiansen (2011) WO 2011/026863 Copyright © 2015 Chr. Hansen A/S. All rights reserved The Approach: A Multi Step CSI Process * S. thermophilus Step 2: Perturbed Glucose Metabolism Selection of mutants with impaired glucose metabolism resistant to 2-deoxy glucose*** Glucokinase (glcK) negative mutants give resistance to 2-deoxy glucose ** To circumvent bypass of glcK, the glucose transporting PTS system has to be inactivated Selection of mutants resistant to higher levels of 2-deoxy-glucose gives mutations in PTS system transporting glucose Glucokinase-negative galactose-fermenting manPTS-negative S. thermophilus mutants (Sweety ST) *: Johansen et al. (2013) WO 2013/160413A1 **: Adapted from Hols et al. (2005) FEMS Microbiol Rev ***: Youderian et al. (1999) J. Bacteriol Copyright © 2015 Chr. Hansen A/S. All rights reserved Glucokinase-negative Galactose-fermenting manPTS-negative S. thermophilus Mutant (Sweety ST) Sweety ST enhances sweetness of fermented milk by excretion of glucose 𝑅𝑒𝑙𝑎𝑡𝑖𝑣𝑒 𝑆𝑤𝑒𝑒𝑡𝑛𝑒𝑠𝑠 𝐼𝑛𝑑𝑒𝑥 = 16 ∗ 𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 33 ∗ 𝑔𝑎𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 74 ∗ [𝑔𝑙𝑢𝑐𝑜𝑠𝑒] 750 Copyright © 2015 Chr. Hansen A/S. All rights reserved Yoghurts made with Sweety ST & LB give limited added Sweetness Sweety ST enhances sweetness of fermented milk by excreting glucose which gets consumed by Lb. delbrueckii subsp. bulgaricus 𝑅𝑒𝑙𝑎𝑡𝑖𝑣𝑒 𝑆𝑤𝑒𝑒𝑡𝑛𝑒𝑠𝑠 𝐼𝑛𝑑𝑒𝑥 = 16 ∗ 𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 33 ∗ 𝑔𝑎𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 74 ∗ [𝑔𝑙𝑢𝑐𝑜𝑠𝑒] 750 Copyright © 2015 Chr. Hansen A/S. All rights reserved Non-glucose fermenting Lb. delbrueckii subsp. bulgaricus growing on Lactose * Maintaining the sweetness in yoghurt Carbohydrate profile & relative sweetness Lb. delbrueckii subsp. bulgaricus growing in milk: Prevent consumption of excreted glucose Selection of mutants resistant to 2-deoxy-glucose on plates with lactose as sole carbon source to give mutations in PTS system transporting glucose Mutants do not grow on glucose as sole carbon source *: Johansen et al. (2013) WO 2013/160413A1 **: Adapted from Hols et al. (2005) FEMS Microbiol Rev Sweety Lb. delbrueckii subsp. bulgaricus mutants excrete glucose and grow on lactose ** Non-glucose fermenting Lb. delbreuckii subsp. bulgaricus mutant (Sweety LB) Copyright © 2015 Chr. Hansen A/S. All rights reserved A Combination of Sweety ST & Sweety LB enhances Sweetness of plain Yoghurt by 3-fold Yoghurt fermentations with both Sweety mutants 𝑅𝑒𝑙𝑎𝑡𝑖𝑣𝑒 𝑆𝑤𝑒𝑒𝑡𝑛𝑒𝑠𝑠 𝐼𝑛𝑑𝑒𝑥 = 16 ∗ 𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 33 ∗ 𝑔𝑎𝑙𝑎𝑐𝑡𝑜𝑠𝑒 + 74 ∗ [𝑔𝑙𝑢𝑐𝑜𝑠𝑒] 750 Copyright © 2015 Chr. Hansen A/S. All rights reserved Conclusions & Future Perspectives Sweety Tailor made mutants without using of recombinant DNA technology which can be used to: Make natural plain yoghurt with increased sweetnesss (2-3 x more sweet) without increasing the caloric content Reduce the amount of added sucrose (by 10 g/l) while maintaining the same sweetness (cost saving & calorie reduction) Significantly lower the levels of residual lactose after fermentation thus making sweety yoghurts a better choice for people with lactose intolerance Taste Texture Yield Shelf life Health benefits Take out Add in Sugar, Fat, Protein.. Texturizers, Stabilizers Preservatives SWEETY™ Copyright © 2015 Chr. Hansen A/S. All rights reserved Thank you for your attention Copyright © 2015 Chr. Hansen A/S. All rights reserved

© Copyright 2026