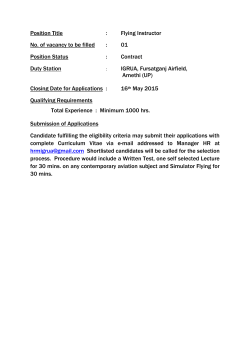

Mar #100