Hurricane Recovery Operations Overview

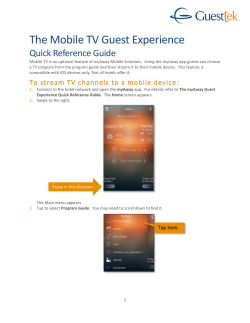

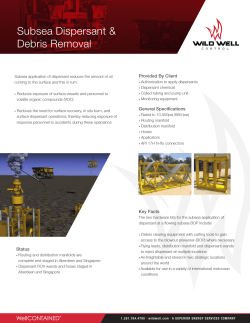

Hurricane Recovery Operations Overview Dick Green General Manager, North Sea Business Unit Wild Well Control Presentation Overview • • • • • • • • • Challenges of Recovery Ops Project Safety Phase 1 – Survey/Initial Assessment Phase 2 – Project Planning Phase 3 – Site Prep/Debris Removal Phase 4 – Well Bore Access Phase 5 – Well Intervention/P&A Phase 6 – Site Clearance Misc. Tool Technologies Platforms Destroyed Platforms Destroyed # Operators Involved Water Depths Hurricane Katrina 44 10 30 - 340 ft Hurricane Rita 69 27 28 – 254 ft Hurricane Ike 52 26 25-480 Totals 162 63 * * Some Operators sustain damages in both hurricanes. The Challenge •Stored Energy •Explosion Danger from Trapped Gas •Indeterminate Integrity and Interactions of Structure •Must Avoid Disturbing Wells Until Pressure Is Bled Off •Wells Sometimes Breached in Inaccessible Locations •Identification of Structural vs. Product-Containing Pipes •Dive Excursion Limits; ROV Tether Constraints •Poor Structural Drawings and Well Records •Offshore Logistics & POB Limits •Station-Keeping Limits and Run-Offs Marine Life in Area •Marine Life in Area •Regulatory Oversight of Releases •Offshore PERSONALITIES •High Pressure Gradients “DP” •Visibility esp. Near-Shore •Adherence to Client Policies •Ongoing Work in Area •High Pressure Gradients And Much More! GOM 2003 Med 2004 Angola 2004 GOM 2005-2008 Typical Storm Damage Referred to as “Downers” Typical Storm Damage Referred to as “Leaners” Typical Storm Damage For “In-Between-ers” Shallow Debris and Accessible Wellheads Deck Settled on Wellheads Extensive Damage Deeper Water Mud-line Failure Subsea Recovery Project Types Project Safety Safety Management System Employee Orientation Management of Change is a key part of the operations Site Safety Plan and Job Safety Plan Emergency Response & Evacuation Plan Spill Contingency & Recovery Plan Safety Award Program Emphasis On Awareness & Teamwork Recognition & Involvement • On-board Safety Representative • JSA’s & JSEA’s • Permit to Work • STOP Program • Risk Assessment Program • HazMat Plan • MSDS’s Preliminary Data Gathering – Latest operational platform survey – As built platform drawings and structural drawings – Slot location and well relationships – Well bore schematics – BHP and surface pressure data – Status of wells – Wellhead schematics – Pipeline maps – Field maps – Any other pertinent data or information Assessment Objectives of Assessment – – – – – – – – – Dive Safety Debris removal targets Well intervention Vessel selection Tooling requirements Scheduling of project Cost scenarios Risk scenarios Develop and execute (Debris / Intervention) plans Survey Equipment – ROV – Mesotech Sonar – Echoscope Multi-beam Sonar – Viper Fish Data Recorder – Export to RHINO Model – Create a mosaic of debris field Phase 1 – Survey Typical Data Gathered Photographs ROV Footage Mesotech Well Files As-Built Drawings 3-D Sonar/Imaging Phase II Project Planning • Cost Estimation – Budgetary and forward planning • Scheduling – Determination of project timelines and milestones • Asset vetting and surveying – Surveys of OSCV and support vessel (s) • Asset selection & procurement – Determination of fit for purpose – Contracting and negotiations • Logistics – Equipment – Personnel – Dock Facilities Working Model of Downed Platform Developed From Survey Info Review Survey to identify wellhead access and visible conductor breaches which dictate well bore access plan Before Katrina After Katrina Develop “As Built” vs “As Is” Models Procure Equipment & Services • Personnel • • Experienced Recovery Personnel Service Technicians • Vessels • • • DP Moored Jack-up • Dive Systems • • • Surface Mixed Gas Saturation • Navigation and Positioning • Survey & Mesotech • Cutting Tools • Construction & Wells • Wellheads • ROV & Tooling • • • • Hot stabs AHPU Chop saws, grinders, etc. Subsea Lighting • P&A Equipment • • • Subsea BOP/Lubricators Pumping Wireline Select Vessel • • • • • Water Depth Debris Field/Bottom Conditions Lift Capacity Deck Space POB DP 2/3 Moored Lift Boat/Jack-Up Phase III Site Prep/Debris Removal Phase III-Site Prep/Debris Removal – – – – – – – – – – Jacket Technical Data Sheets Lift Size And Weight Philosophy Cutting And Shearing Methodology Rigging Philosophy Dive Safety and Navigation Debris Placement / Removal & Mapping Debris Disposal (If not reefed or required) Stored Energy Issues (safety contingencies) ROV Support (Visual & Intervention Support) Media & Data Capturing / Storage (Viper Fish) Phase III – Site Preparation Typical Equipment Shears ROV Tooling Diamond Wire Diver Burning/Hand Cutting Gated Shear Minimum Debris Clearance to make safe for Well Access & Intervention ops Area where Hot Tap, Wellhead Install and Intervention Ops will take place Phase IV Well Access Well Investigation and Access • • • • • • • • Survey and Trace conductors, Tag conductors w/ well #s. Evaluate Access Options Repair existing wellhead and kill well if wellhead is accessible Strongback and Hot Tap or Direct Hot Tap if wellhead is not accessible Once Secure make DWC Cut on Conductors Wedding Cake Casings and Install Wellhead Install tubing hanger/ pack off and tension tubing Install Tree Secure well pending final P&A Initial Wellbore Access Through the Wellhead (if accessible) or Hot Tap the Casing/Tubing Phase IV – Well Bore Access Typical Equipment Diamond Wire Longitutadal Cutting Tools Strong Back Hot Tap Radial Cutting Tools Direct Hot Tap (if required) Direct Hot Tap Basic Example Direct Hot Tap is faster than a conventional hot tap with strongback, ring & peel. But it must be used appropriately… Re-Heading on vertical Fresh Head Wedding Cake Install Wellhead Phase V Well Intervention / P&A • Phase V Well Intervention – – – – – – – – – – Wellhead Intervention Direct Hot Tap Strong back placement as required Hot Tap of casing strings Shearing of conductors as required Annuli isolation Pollution containment & decanting Pumping of kill fluids and cement Removal of horizontal sections of conductors Install wellheads on verticals Wells Secured Awaiting Final P&A Plug & Abandonment Operations Riserless Subsea Intervention Well P&A Schematic Miscellaneous Tool Technologies SeaSun Subsea Lighting System Excavation Phase VI Site Clearance Even in the presence of a reefing permit, the platform deck is often targeted for removal due to hydrocarbon-containing equipment. Platform & Wreck Removal • Experience and personnel to plan and execute the salvage and or recovery of vessels and platforms • Heavy Lift Assets – Superior Performance • 800 ton DB Questions? Questions?

© Copyright 2026