Ahmed Noori AL Raisi Asst. Directorate Of Public Health

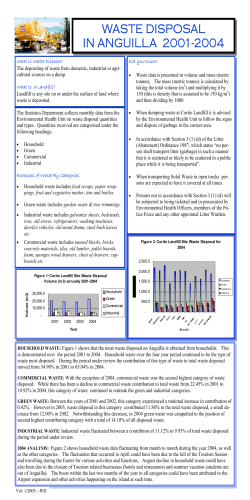

Waste Management in Muscat 60322 187145 123016 Quriyat Al Amerat Al Seeb Bowsher Matrah 354721 529480 10684 33879 79579 Matrah Bowsher Al seeb Al Amerat 198090 Quriyat 134352 - Waste collection and city cleaning - Underground waste collection system - Transfer station - Engineered landfill - Green Waste management - C&D waste management - Rehabilitation of the closed dump - site in Muscat Waste Management is a public service affecting both health and environment. Waste management is include collection, transportation, disposal and treatment responsible body for handling the solid waste management in Governorate of Muscat takes care of all stages of the waste from collection till disposal own resources i.e. human resources and equipment city and road cleaning is the responsibility of the Municipality Refuse Collector 11 24 10 Matrah Bowsher Al Seeb Al Amerat Quriyat 41 39 [CELLRANGE]; [VALUE] [CELLRANGE]; [VALUE] [CELLRANGE]; [VALUE] [CELLRANGE]; [VALUE] [CELLRANGE]; [VALUE] AL AMERAT Engineered Landfill Present situation Engineered Landfill 1 المردم الهندسي بالعامرات المرحلة KEY FIGURES Void Volume to filling : 1 000 000 m3 • Expected quantities : 250 000 tons per • year Start date : February 2011 • Expected life time : 4 years • Actual quantities : > 800 Tons a day (7 • days a week) Opening Time : from 06.00 am to 6.00 • pm AL AMERAT SANITARY LANDFILL CELL 2 2 المردم الهندسي بالعامرات المرحلة 2400 000 ton 14.2 ha Lining Cell bottom Leachate treatment system Cell 1 covering Cell 2 In Progress final covering BioGas colletion & traitment Materials requirement and balance for the site operation مليون طن2.4 هكتار14.2 حماية منظومة معالجة العصارة 1 تغطية نهائيةللخلية 2 تغطية حسب التقدم للخلية .تجميع و معالجة االنبعاثات تحضير المواد االزمة للتغطية اليومية طوال مرحلة التشغيل AL AMERAT SANITARY LANDFILL CELL 2 CELL BOTTOM LINING The landfill engineering barrier will comply with USEPA design and technical requirements and will consist of the following lining system from bottom moving upward ad as shown in the below detail. AL AMERAT SANITARY LANDFILL CELL 2 LEACHATE TREATMENT SYSTEM A reliable, flexible and very robust system for the treatment of the effluent which guarantees to meet the outlet requirements. Evaporation pond AL AMERAT SANITARY LANDFILL CELL 2 LEACHATE TREATMENT SYSTEM We propose to treat the leachate using the following steps: • A Lagoon • An anaerobic pond • A Membrane BioReactor (MBR) • 2 successive aeration basins for maximal COD/BOD5 and NH4-N reduction • Ultrafiltration for retention of biomass • A Reverse Osmosis (RO) plant for removal of nonbiodegradable COD-fraction, AL AMERAT SANITARY LANDFILL CELL 2 LEACHATE TREATMENT SYSTEM ANAEROBIC POND AERATION SYSTEM ULTRAFILTRATION (UF) REVERSE OSMOSIS AL AMERAT SANITARY LANDFILL CELL FINAL COVER The landfill engineering barrier will comply with USEPA design and technical requirements and will consist of the following lining system from bottom moving upward ad as shown in the below detail. AL AMERAT SANITARY LANDFILL CELL 2 ٍ BIOGAS COLLETION & TRAITMENT SYSTEM Efficient and effective landfill gas management system to provide full environmental control by coordinating and integrating gas monitoring, collection, extraction and the gas supply to flare or utilization projects No pre-segregation - No segregation or recycling plant - Some recycle materials collectors \ - FOOD GREEN WASTE CARDBOARD PAPER 13% 12% TEXTILE 1% 0% 3% 1% 1% SANITARY TEXTILE 0% 0% PLASTIC BOTTLES 1% PLASTIC WRAPS 12% 3% OTHER PLASTICS METALS 3% GLASS 10% WOOD OTHER COMBUSTIBLES 20% NON COMBUSTIBLES 10% HAZARDOUS WASTE 3% 7% WEEE projects are being carried out for rehabilitation of the entire closed dump primary studies to collect data on the sites Geotechnical investigation Topographic survey Waste Characterization The waste characterisation exercise has been completed for all three dump sites. Inerts, soil, concrete, rocks and stones comprise from 63% to 91% of the wastes. Waste Composition at Al Seeb Other residues, 1.46% Paper and cardboard, 1.75% Plastics, 3.79% Concrete, rocks and stones, 13.07% Wood, trees and branches, 2.11% Textiles, 2.90% Inerts and soil, 74.28% Landfill gas flow rate obtained through extrapolation of pump test over entire site is as follows: Site Gas Production rate (cu.m/hr) Al Amerat Al Seeb Bausher 2,300 7,000 3,400 Based on flow rates, recommended flare capacity 4,000 m3/hour (2 flares at Seeb). Gas Collection 9% Excellent Acceptable below standard 36% 55% Privatization of the waste collection will start in Muscat at 2016 (Beah)

© Copyright 2026