Ontario Canola Growers Association April 2015 Newsletter

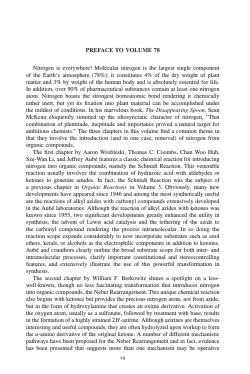

Ontario Canola Growers Association April 2015 Newsletter President’s Message The slow warm up this spring provides a good demonstration of the value of including canola in your rotation in order to get your winter wheat crop planted and off to a good start. If you are in southern Ontario, be sure to consider that extra yield for winter wheat going in right after canola when you are deciding on rotation options. On the heels of last year’s successful return to “bin buster” yields in southern Ontario, we anticipate acres in this area are poised to rebound. In the northern Temiskaming area, learning more about controlling Swede Midge remains a priority for OCGA. We will be monitoring swede midge traps on several of last year’s canola fields for indications of how quickly populations decline and the positive effect of canola within a more diverse rotation. In central Ontario we will continue our swede midge control trials adding the variable of moving to larger field trials and we will be offering swede midge traps to agronomists and producers who are committed to monitor for improved control. See more on this on Page 2. Our commitment at OCGA is to continue to provide the tools for “Profitable Canola Production.” With the ongoing issue of access to rail freight in the west, Ontario basis is high again, providing opportunities for profitability for Ontario farmers again in 2015. I assure you that OCGA is working hard to find a management program to control Swede Midge and return canola as a viable and sustainable rotation option for Ontario Farmers. Have a safe spring season, Terry Phillips, President, Ontario Canola Growers Association Canada Post Publications Agreement #40013291 2015 Swede Midge Monitoring Monitoring your swede midge populations is part of the 2015 recommended swede midge management program. OCGA will sponsor the trap costs of any grower who monitors a canola crop for the first 8 to 10 weeks after emergence and shares the results with OCGA on a bi-weekly basis. This is how it will work: To effectively monitor swede midge the population counts must be recorded twice each week for 8 to 10 weeks after emergence. This is a commitment that will take time during the busy spring season. If you do not have the time to commit to this, we suggest you consider the services of an agronomic consultant to help. 1. Send an email to [email protected] to request monitoring supplies, including: Name Home address and location of field (GPS and physical location). Phone contact (preferably cell phone). 2. If you are an agronomist, please include the same information for each of the growers you will be providing monitoring services for. 3. Participate in the monitoring program by checking traps bi-weekly and sending the swede midge population numbers to OCGA. We will make this as easy as possible for you. You can text or phone your population counts in right from the field. OCGA will assist with your initial identification of swede midge caught on trap liners. Please note: We recommended a 20X magnifier (10X minimum) for identification. The swede midge populations you report will be posted on the swede midge monitoring map on OCGA’s website at www.ontariocanolagrowers.ca Alerts on rising swede midge population counts will be circulated by email and other social media. Page 2 Ontario Canola Growers Association April 2015 Newsletter Goodbye and a Huge Thank You to Brian Hall I’m sure most have heard the sad news (well at least for us) that Brian Hall will be retiring from his position as Canola Specialist with OMAFRA later this spring. What a gap this will leave for OCGA and what gratitude and appreciation we extend to Brian for all the effort and dedication he has provided to Ontario’s canola industry. Brian demonstrated great commitment to Ontario farmers through his career’s work of improving and sharing credible information on optimal canola production. There have been so many occasions when someone would recount to me a story of Brian working on trials right through a weekend or in the pouring rain or loading his equipment up late at night only to return for more the next morning. What Brian contributed to the Ontario canola industry is really quite outstanding. Because of OCGA’s small size as an organization, large scale research projects were generally out of our economic reach but Brian was always keen to run field trials on the current April 2015 Newsletter canola issues. He has been tireless in the help he gives to producers. His phone rings constantly. He has spoken at virtually all of our crop tours and annual meetings. He has provided most of the content for our newsletters. Really he was the meat in our sandwich and his loss will be felt greatly. At the time of writing this newsletter we had not yet received a decision from OMAFRA on whether they intend to continue this position. If not, this will most certainly be a tremendous loss to our industry. Quite frankly it will be huge loss and I am not sure how we can effectively carry on without the support of this position. On behalf of the Ontario Canola Growers board, I would like to say a huge thank you to Brian. Your career’s work contributed significantly to our understanding of how to grow canola through profitable and sustainable practices. You will be greatly missed. Carrie James, Ontario Canola Growers Association Ontario Canola Growers Association Page 3 Nitrogen Management Options in Canola for 2015 by Brian Hall, OMAFRA, Canola Specialist 2015 is shaping up to be a challenging year for keeping canola production costs in line with potential returns. Rising fertilizer prices have put the squeeze on potential profits and nitrogen management will play a key factor. The ideal goal is to apply enough nitrogen so that any higher rate won’t produce enough extra yield to pay for the added nitrogen. This nitrogen rate is called the most economical nitrogen rate (MERN) which is commonly stated in corn and canola nitrogen recommendation tables. However identifying this optimum N rate is complex given nitrogen dynamics in soil. What Rate of Nitrogen? Canola has high nitrogen requirements. A one tonne/ac canola crop will remove 85 lb N/ac in the grain + uptake an additional 55 lb N/ac in the straw = 140 lb/ac in total. To optimize the return on nitrogen growers need to account for the price of nitrogen and canola in deciding on nitrogen rates. Table 1 (see page on right), shows the MERN based on the relationship between canola price and nitrogen price. For example using a canola price of $500/tonne and nitrogen price of $615/tonne for Urea ($0.62/ lb of N); the most profitable N rate is estimated at 88 lb N/ac (195 lb/ac Urea). These results do show that for 2015, there is little reason to reduce or increase nitrogen rates, and you should continue to use your optimum rate or 120 lb N/ac. Nitrogen rates have generally increased since these trials were done from 2001 to 2003, with 100 to 120 lb N/ac being more commonly applied today. From 2010 to 2012 we conducted a number of on-farm trials to review these nitrogen rates. Results from these trials do support the higher rate of N as being most profitable. These trials showed that returns improved by $19/acre on average by using 120 lb N/ac vs 80 lb N/acre. However, returns were reduced by using 160 lb N vs the 120 lb N rate. There was variability in response to nitrogen in these trials, where the 120 lb N rate was more profitable than the 80 lb N rate only 57% of the time. This is not the whole story, because many would rightfully ask what the biggest loss in yield was from only applying 80 lb N/ac. At one location in 2011 (very wet spring) the 120 lb N/ac rate yielded 740 lb/ac (over 40% >) more than 80 lb N. I suspect at this site which had a clay loam soil, loss of nitrogen was due to denitrification (lost to atmosphere) from prolonged wet saturated soil conditions. Page 4 Fine Tuning Nitrogen Application Timing Starter N — Seed row placement of N can be efficient, but is not nearly as beneficial as that of seed placed phosphorus. Because of ammonia toxicity problems with starter N, rates should not exceed 10-20 lb N/ac in seed placed fertilizer. On sandy soils or very dry conditions, do not use more than 10 lb N/ac. There is no difference in seed row safety between ammonium nitrate, ammonium sulphate and urea. One way to apply higher rates of N in starter is to use polymer coated urea (ESN). The safe rate of ESN can be up to 2-3 times the amount of straight urea. Growers need to note that MAP (11-52-0) is usually safe at rates below 45 kg/ha (40 lb/ac) or 22 kg/ha (20 lb/ac) of actual phosphorus. MicroEssentials S15 (1333-0-15S) has also demonstrated better canola seed safety at similar phosphorus rates to MAP. Do not apply potash or sulphur in starter fertilizer because of risk of injury and reduced emergence. Timing of Application – Canola is like many other field crops that typically utilize less than 50% of the applied nitrogen in the year of application. The goal in timing nitrogen application is to supply adequate N when the crop needs it without it being lost to the environment or supplying more than the crop can utilize. Canola requires only a small fraction of total N up to the 5th leaf stage at which point rapid vegetative growth requires a large amount of N up to pod development. Canola has an extremely rapid growth between the rosette stage and flowering, unmatched by most other crops. This huge biomass production is driven directly by nitrogen and is closely related to yield. Two approaches to reduce the risk of N losses to leaching or denitrification and improving nitrogen efficiency use are by either split nitrogen application timing or use of a ‘stabilized’ nitrogen source like ESN at planting. ESN®, Environmentally Smart Nitrogen is a polymer coated urea prill that slows the release of nitrogen, thereby reducing potential for loss due to leaching or denitrification. The cost of ESN adds about $0.23 per lb of N to the cost of urea. ESN can be used to replace part of the nitrogen supplied from other sources; thereby providing both a readily available and slow release N source that is more economical than straight ESN. ESN is reported in tight supply this spring, so growers are advised to contact their dealer early. In talking to one dealer, they reported that a secondary benefit of ESN is improved fertilizer flow ability. Adding some ESN in with some other fertilizers improves the flow ability in certain applications like air-fertilizer carts. Ontario Canola Growers Association April 2015 Newsletter Canola price per tonne2 Table 1 $400 Nitrogen Cost $/lb N1 $440 $480 $520 $560 Most Economic Nitrogen Rate (MERN) lb N/ac 0.55 85 88 90 92 94 0.60 82 85 88 90 92 0.65 79 82 85 88 90 0.70 76 80 83 86 88 0.75 73 77 80 83 86 0.80 70 75 78 81 84 1. Nitrogen is cost per pound actual N. Example: In 1 tonne of urea (45% N) there is 992 lb N and if urea cost is $615/t; the cost of N is $0.62/lb N. 2. Based on Ontario nitrogen rate trials on hybrid canola from 2001 to 2003. Table 2 Canola Nitrogen rate trials 2010 to 2012 - 21 total sites 2010-2012 Canola Nitrogen Rate Response1 Nitrogen Rate lb/ac Average Yield1 lb/ac 80 1989 120 2184 160 2247 Yield Increase vs 80 lb N/ac %> $ return/ acre vs 80 lb/ac N rate2 % Dollar wins vs 80 lb N/ac3 198 9.8% $19.00 57% 258 12.9% $8.93 48% lb/ac 1. Results are average of 21 trials; 6, 7, & 8 conducted in 2010-2012 respectively. 2. Dollar return per acre vs 80 lb N/ac rate is increase or decrease in returns at 120 or 160 lb N/ac using nitrogen cost of $0.62 /lb N (urea= $615/t) and canola price of $500/tonne. 3. % Dollar wins is % of trials from 2010 to 2012 in which returns were improved with either 120 or 160 lb N/ac vs 80 lb N/ac. Table 3 Comparison – Nitrogen Cost/acre based on 120 lb N/ac rate Program Nitrogen Treatment N rate & timing Cost/ac Total Cost/ac 1-3 Ammonium sulphate @ 100 lb/ac 21 lb N/ac $22.00 $22.00 1 Urea (46-0-0) Pre-plant incorporated 100 lb N/ac $61.00 $61.00 2 Urea:ESN blend (75:25) Urea (46-0-0) ESN (44-0-0) Preplant incorp. 70 lb N/ac as urea 30 lb N/acre as ESN 120 lb N/ac total $42.70 $26.30 $69.56 3 Split Application Urea (46-0-0) UAN (28-0-0) 70 lb N/ac Pre-plant 30 lb N/ac Post emergent 120 lb N/ac total $42.70 $18.30 + $10.00 UAN $71.00 This table compares nitrogen cost for treatments mentioned above. Note for each of the programs listed, 100 lbs/acre of ammonium sulphate (21-0-0-24) would be applied in addition to other nitrogen sources applied pre-plant application to supply 24 lb/ac sulphur. April 2015 Newsletter Split N Application – Split applying N has gained a lot of traction with corn producers and some canola growers. Delaying part of the N application can reduce the risk of N loss and crop deficiency, improve profitability by improving nitrogen use efficiency and benefit the environment. It also allows the grower to assess their crop before committing to applying the full allotment of nitrogen. One strategy that is being used is to pre-plant apply the amount of nitrogen that might suffice in most years (e.g. 80-90 lb N/ac). Then when the canola reaches the 3-5 leaf stage, reassess the stand and yield potential, adjust for spring weather related potential N losses and apply up to an additional 40 lb N/ac. Growers contemplating split applying nitrogen should have most/all of the nitrogen applied before the 5– 6 leaf stage (rosette) when canola enters its rapid growth stage and the demand for nitrogen is greatest. Canola producers in Western Canada that are split applying nitrogen are using either dry or liquid nitrogen sources. If using a dry nitrogen source, either ammonium nitrate, ammonium sulphate or urea can be used. Agrotain® (NBPT) should be used with urea in top dressed applications to reduce volatilization losses and applied below crop residue. If applying a liquid N source like UAN or ammonium thiosulphate, use a streamer bar at the correct height to minimize directing nitrogen onto the canola growing point. Applying in the evening, under cloud, heavy dew or prior to a rain will also help minimize the risk of leaf burn. Split nitrogen may be uneconomical because of extra cost of application, damage to the standing crop or missing the correct timing due to weather. Wait until the crop has sufficient leaf area (i.e. 3-4 leaves) before applying to minimize leaf burn damage. Summary: In extremely wet springs and with major rain events in May and June, some loss of nitrogen occurs in canola fields. It s important to understand the risk of nitrogen loss from your fields to help in deciding on the value of ‘stabilized’ nitrogen products or split nitrogen application. On coarse textured soils, leaching of nitrate nitrogen is the biggest concern. Fine textured soils hold on to water tightly limiting downward movement and denitrification plays a larger role in potential nitrogen loss. Denitrification occurs when soils become waterlogged for 2-3 days so that nitrogen is converted to nitrogen gas and lost to the atmosphere. Ontario Canola Growers Association Page 5 The Canola Council of Canada has produced a video that describes the key factors involved in establishing a strong canola stand. Growers share their experiences in a question and answer format. Growers share: What seeding rates they use and why. What speed they plant at. How often they check drill performance for depth and evenness. The video is posted on the OCGA website at: www.ontariocanolagrowers.ca. A canola crop that emerges evenly with seven to ten plants per square foot is better able to compete with pests, mature more evenly and provide a better return on your investment. Spray Weeds Early For Higher Yields! Trials have shown a 10% yield improvement by spraying at 1 to 2 leaf stage versus the 5 + leaf stage. Concentrate on controlling weeds that emerge with the canola, and less on weeds that come up after the 4 to 6 leaf stage. Page 6 Ontario Canola Growers Association April 2015 Newsletter Calculating Canola Seeding Rates CANOLA SEEDING RATE (lb/ac) Establishment is the greatest challenge in growing canola, because it is sown shallow where soil is most subject to rapid drying. 1000 Seed Weight gm Seeding rates and plant counts are critical because of wide differences in seed size with newer varieties and seeding by pounds per acre can really throw off the actual plant stand count. An error in seeding can be a costly mistake. Seeding rates need to be based on the 1000 kernel seed weight (grams per thousand seeds). Begin with the desired final plant stand. In canola the optimum plant stand is 7 to10 healthy plants/sq foot (5 plants/ft2 is minimum). In 7.5 inch rows this is equivalent to 4.5 to 6 plants per foot of row. Target seeding rates need to account for large differences in seed size between varieties and seed lots. Under good seeding conditions a 75% emergence rate is reasonable, but under average conditions a 60% emergence rate is a reasonable reference point to calculate seeding rates. Target Seeding Rate lb/acre 75% Emergence 60% Emergence 6.7 seeds per foot of row 8.2 seeds per foot of row 2.5 2.6 3.0 Grams of Seed per opener per 100 feet (30.5 m) of travel (7.5 inch rows) 75% Emergence 60% Emergence 3.1 1.7 2.0 3.1 3.8 2.0 2.5 3.5 3.6 4.4 2.3 2.9 4.0 4.1 5.0 2.7 3.3 4.5 4.6 5.6 3.0 3.7 5.0 5.1 6.3 3.3 4.1 5.5 5.7 6.9 3.7 4.5 6.0 6.2 7.5 4.0 4.9 6.5 6.7 8.2 4.4 5.3 Note: Use 75% emergence rate under good/optimum seeding conditions. 60% emergence is based on 90% germination and 32% seed mortality when seeding under less ideal conditions including soils prone to crusting, very early seeding ,or poor depth control. These seeding rates are based on final plant population of 8 plants/ft 2 . Remember these key points when seeding... Calibrate seeding equipment before heading to the field! Bulking of seed with MAP (11-52-0), pelletized sulphur or corn cob grits are options for improving seeding rate accuracy. Seeding through the grass seed box is another option, with the seed tubes inserted into the disc openers. Check fluted cup opening across the drill. Watch for excessive grinding of seed in seed cup, especially under low humidity conditions. Speed kills. Even emergence is more important than plant spacing. Drill bounce is more of a problem at speeds over 5.0 mph. Trials have shown that compared to 5.0 mph, a speed of 5.5 mph required an extra 1.5 lb/ac seed to achieve the same plant population. Ideal target seeding date is when soil temperatures are 50 C or higher, but let soil conditions and 5-7 day weather forecast guide you on when to seed. Seed 1/2" to 1” deep into a firm and slightly cloddy seedbed, keeping moisture near the surface. Deeper seeding reduces emergence and vigour, decreases seedling and root growth, and increased risk of crusting issues. Packing before and after planting has given the best results in a dry year. Be aware that packing following planting covers over the seed furrow, and can place seed deeper than intended. If moisture is more than five cm (2 inches) deep, it is advisable to wait for moisture. Avoid having the seed start to germinate and run out of moisture. April 2015 Newsletter Ontario Canola Growers Association Page 7 The Canola Challenge 2015 – Six Chances to Win! Can YOU bring in the winning yield? Ontario growers are bringing in amazing yields. The Canola Challenge recognizes their accomplishments. And then they share their winning management practices. A Win – Win for all! 1st place winner – $2,000 cash 2nd place winner – $1,000 cash 3rd place winner – $ 750 cash 4th, 5th and 6th place winners – $500 cash Winners will also receive a “Canola Challenge Winner” jacket. INTENT TO PARTICIPATE How Do You Enter and What are the Rules? Fax or email information below by July 17, 2015 1. Complete “Intent to Participate” and submit by July 17, 2015. Grower Name ____________________________________ 2. Work with a supporting agronomist. 3. Minimum 10 acre canola plot. 4. Record your yield from 1 acre of your field which must be recorded by weigh wagon and verified by your supporting agronomist. 5. Record your crop management and yield information and submit to OCGA by Nov 2, 2015. 6. Entry must be for one individual grower (one jacket per entry). 2015 CANOLA CHALLENGE Grower Phone ___________________________________ Grower Email Address _____________________________ Supporting Agronomist _____________________________ Agronomist's Company _____________________________ Phone: 519-986-3519 Fax: 519-986-3811 Email: [email protected] Box 106, Markdale, ON N0C 1H0 Canola Challenge Sponsors

© Copyright 2026