Tuepm2- Emily Darchuk OSU Milk Hauling

Impact of hauling practices on raw milk quality Emily Darchuk and Dr. Lisbeth Goddik Image Source: https://mackinsondairy.files.wordpress.com/2014/11/cows-pasture.jpg Background Study Objectives 1. Determine the impact of operating trucks for an extended period of time (24 hrs and up to 10 loads prior to CIP) 2. Impact of seasonality 3. Impact of different cleaning procedures Hypothesis: 1) Extended use of tanker trucks will negatively impact raw milk quality 2) Impact will be more pronounced in summer 3) Any impact can be mitigated through intermittent cleaning treatments 3 Study Methodology 4 Study Background A ) Winter Study • Short duration and high frequency tanker use • Up to 9 loads per 24 h with 1-5 farms per load • Average temp: 37°F B ) Summer Study A B • Short duration and high frequency tanker use • Loads averaged 7 per 24 h with 1-3 farms per load • High temp: 97°F 5 Study Design • Impact of different cleaning procedures 1. 2. 3. 4. Standard use ( 24 hr CIP) Water rinse after each load Water rinse after each load & sanitizer treatment after 12 hrs Sanitizer treatment after 12 hrs • Blocked design to account for variability • Truck effect • Sample location (front vs back) • Day effect 6 Areas of Investigation Producer Milk Tanker Milk Provide baseline milk quality data Show the effect of hauling Frequency: •Sample from every farm bulk tank loaded into truck Frequency: •Sample from the front and back of every load Testing : •Bactoscan (IBC) •Thermophilic Sporeformer (TSC) •Preliminary Incubation (PI) Testing: •Bactoscan (IBC) •Thermophilic Sporeformer (TSC) •Preliminary Incubation (PI) Tanker Surface Efficacy of cleaning Frequency: •Before and after each treatment Testing: •Sponge swabs (APC) •ATP Swab (post cleaning treatment only) 7 Study Results 8 Measure of Raw Milk Quality: No impact due to hauling Winter Sanitizer Standard Use (Control) Water Rinse & Sanitizer Water Rinse Difference in Log cfu/mL 0.5 0.25 0 -0.25 -0.5 0 1 2 3 4 5 6 7 8 9 1 2 3 4 Load Number 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 Load Number Load Number Water Rinse Water Rinse & Sanitizer Load Number 9 Summer Sanitizer Standard Use (Control) Difference in Log cfu/mL 0.5 0.25 0 -0.25 -0.5 0 1 2 3 4 5 Load Number 6 7 8 1 2 3 4 Load Number 5 6 7 1 2 3 4 Load Number 5 6 7 1 2 3 4 Load Number 5 9 6 7 Measure of Cleaning Efficacy and Tanker Sanitation Plant Swab Data 4 3.5 cfu/900 cm2 3 ATP DATA PASS < 150 RLU 2.5 2 1.5 1 0.5 0 Plant A Plant B Winter Summer Pre Rinse Post Rinse 10 Discussion of Results • Temperature • All loads arrived <45 °F • Tanker insulation effective in maintaining cold temperature • <4 °F per 24 hr • Time • All loads had short duration within truck (< 5 hr) • Dilution • Limited residual milk left in tanker • Results are based on test methods used, more sensitive methods may find issues that could impact quality down stream 11 Industry Recommendations • Continue current hauling practices • No data to suggest addition of rinses would improve raw milk quality • Rinses could be used as a preventative measure as it does reduce tanker surface bacteria • Focus on conducting scheduled cleans and maintenance of trucks and line • Collect ATP data post CIP for general trending • Focus on maintaining high quality producer milk 12 Future Research • Investigate a more sensitive test methods focused on down stream quality defects • Conduct worst case scenario hauling study • DMI supporting continued hauling research at OSU Contact : [email protected] 13 Acknowledgements • Washington Dairy Products Commission • Gina Shellhammer- Statistician • Dr. Lisbeth Goddik and Dr. Joy Waite-Cusic 14 Thank you ! 15

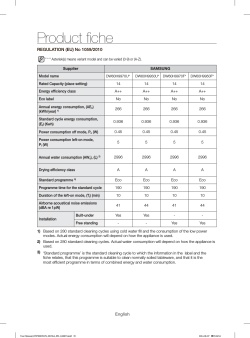

© Copyright 2026