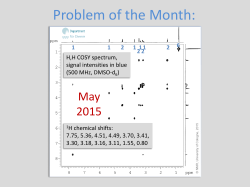

Organic Chemistry