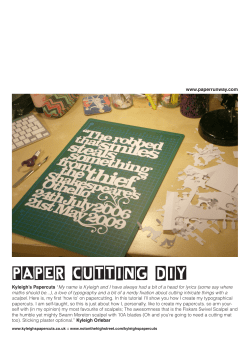

i Setting up Jobs for Production