Yogurt / Ice cream / Pasteurised Milk – a beginner’s guide to processing

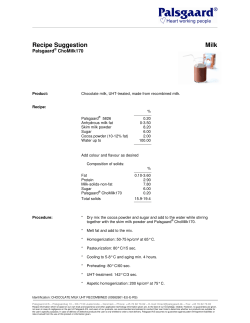

Yogurt / Ice cream / Pasteurised Milk – a beginner’s guide to processing Published in association with the Society of Dairy Technology Contents Introduction and market overview 3 Section 1 - Technical requirements 4 Section 2 - Yogurt 6 2.1. Summary of business plan for Yogurt 6 2.2. Outline manufacture – Stirred Yogurt 6 2.3. Yogurt process flow 8 2.4. Capital and operating costs 9 2.5. Yogurt production area outline plan 10 Section 3 - Ice Cream 11 3.1. Summary of business plan for Ice Cream 11 3.2. Outline manufacture – Ice Cream 11 3.3. Ice Cream process flow 13 3.4. Capital and operating costs 14 3.5. Ice Cream production area outline plan 15 Section 4 – Pasteurised milk 16 4.1. Summary of business plan for Pasteurised milk 16 4.2. Outline manufacture - Pasteurised milk 16 4.3. Pasteurised milk process flow 18 4.4. Capital and operating costs 19 4.5. Milk processing area outline plan 20 Section 5 – Appendices 21 This booklet and the information within are intended as a guide only. Please seek detailed support from your accountant, bank, legal advisor or other specialist support organisations. A list of useful contacts can be found in Section 6 of the DairyCo publication ‘On-farm processing – a beginner’s guide’. Dairy UK has developed a comprehensive guide detailing information on where to source finance, products, training and knowledge for innovation that can be viewed at www.dairyukinfohub.com. The Society of Dairy Technology can be contacted via their web site www.sdt.org 2 Introduction and market overview This booklet is designed to give an overview of the requirements for the capital and cash flow, and some recipes, for the manufacture of yogurt, ice cream and milk. Where costs are quoted these are as a guide only and due to the nature of each project being slightly different, special consideration should be given to the size and suitability of water, electricity and drainage services. Dairy product manufacturing offers a significant opportunity to achieve better returns for the milk producer and with it a more secure future. However, it is hard physical work and demands continuous attention from the maker. Any dairy farmer contemplating these areas of diversification should understand they are not easy options. There has been significant growth in the areas of luxury and indulgent products. It is unlikely any farm-based diversification project will be able to compete in the lower end of the market; the major opportunity lies with the added value, luxury products, with the opportunity to exploit provenance as part of the brand positioning. The liquid milk market is generally split – 60% semi skimmed, 30% whole milk and 10% skimmed milk. Doorstep sales continue to decline unless being specifically developed as more of a ‘service’. These often offer other products or ‘local’, ‘traceable’, ‘farm fresh’ milks. Branded milks are still a large opportunity but must have a genuine unique selling point (USP) and not just a label. ‘Added value’ speciality milks such as milk enriched with Omega 3 remain a significant opportunity and growth sector. Yogurt / Ice Cream and Pasteurised milk processing use similar equipment and have in general terms less technological demands and provide faster cash turn around with significantly less working capital requirements than cheese. For this reason these products have been grouped together. This booklet aims to provide a realistic guide to minimising some of the risks involved in investing in yogurt, ice cream and milk processing. It sets out some of the steps needed to ensure production of the right product, at the right quality and marketed to the right people. The yogurt and pot dessert markets are considered a strong category and one in which consumers demand choice, quality and innovation. Sales have been boosted bringing innovation and new entrants together with significant marketing spend by the major manufacturers of branded produce with year on year growth. The ice cream market can be clearly divided into the commodity ‘value’ sector and the premium, added value sector dominated by major brands and speciality products. 3 Section 1 - Technical requirements - Hazard Analysis Critical Control Point (HACCP) HACCP or equivalent system for safe dairy products production is required by law. Specialist advice will be required in the preparation of this part of the project. Introduction Having deciding to manufacture dairy products, the next step is to prepare the HACCP system for the type of product to be manufactured. The preparation of the HACCP documentation assists in the design of the production premises to ensure that they are safe and appropriate for the products to be made. Some of the key HACCP areas to be considered are given below. This is not meant to be a comprehensive HACCP description for the manufacture of dairy products, but a general overview. Purpose The purpose of a HACCP system is to ensure the production of safe food. Potential hazards to food safety relating to all aspects of the manufacturing process are identified as Critical Control Points (CCPs), and suitable records must be produced to prove that they are controlled. Some benefits of HACCP • Preventative system • Systematic approach • Assists due diligence defence • Facilitates verification activities • Demonstrates management commitment The HACCP system The first task is to address the HACCP pre-requisites, and these are: • Food manufacturing practice (hygiene) • Good laboratory practice • Calibration • Pest management systems • Incident and recall management systems • Preventive maintenance programmes • Training • Supplier quality assurance The next task is to identify the process / product hazards, and document the CCPs on a process flow diagram. 4 Hazard analysis overview • Good personal hygiene • Correct cleaning and disinfection • Adequate pest control • Trained and aware operatives Key process controls • Pasteurisation / cooling • Correct control of the manufacturing / filling process • Correct storage temperature Examples of hazards and recommended food safety principles to consider in relation to milk production Hazard Source / Cause Control / Evidence Raw milk contamination by harmful bacteria / other substances. Poor animal husbandry (eg, animal disease, udder infections). Milk from treated animals not segregated. Contaminated animal feed. Herd health and veterinary records. Medicine / movements book. Mastitis records. Milking machine test reports. Feed supplier assurances. Good herd records and practices. Periodic raw milk antibiotic tests. Growth of harmful bacteria in milk after pasteurisation. Inadequate pasteurisation. Post pasteurisation contamination. Dirty plant and equipment. Poor manufacturing practice. Poor personal hygiene. Pasteurisation records. Calibration certificates. Plant and equipment cleaning and inspection records. Laboratory results. Operator training records. Hygiene training records. There are a number of useful sources for HACCP and good manufacturing process guides. For example: Dairy UK website (Technical Guidance) Basic Food Hygiene Level 2 & 3, and HACCP, and Hygiene in Focus series produced by the Society of Food Hygiene and Technology (SOFHT) 5 Section 2 - Yogurt 2.1 Summary of business plan for Yogurt – case study A real ‘on farm’ operation - an organic farm - was chosen for this exercise to produce a case study. This farm keeps about 110 cows, producing around 3000 litres of milk per day in the summer. The farm commenced on-farm production of clotted cream in 2004. The clotted cream business is now well established but created a large volume of skimmed milk. Initially the skim fraction was used as animal feed on the farm and any left over had to be discarded. To make use of some of the skim fraction, a small production facility was set up to produce yogurt. This facility is capable of producing yogurt regularly, on average three to four days per week, with a maximum capacity of 100 litres per batch per day. The equipment considered in this production facility is as follows: • Milk reception tank • 100 litres batch heater, incubator and cooler • Milk separator • Yogurt pump • Pot filling and sealing unit • Two yogurt chillers • Large walk in chilled store • Hot water boiler and air compressor When considering an appropriate building and equipment it is essential to involve the Environmental Health Officer (EHO), and Planning and Building Regulations Control at the earliest stages. It is also strongly recommended that an appropriately qualified and experienced technology consultant be used to progress planning permission and building regulation approval, and for the preparation of a robust HACCP system. Disposal of waste also requires specialist advice as it will probably be classed as a Product of Animal Origin (POA) and needs to be handled carefully and correctly. 2.2 Outline manufacture – Stirred Yogurt Note: Rigorous hygiene standards must be observed at all stages of the process. 2.2.1 Milk for Yogurt production The highest quality milk should be used for yogurt production as poor bacteriological quality inhibits the growth of the yogurt culture during incubation. Residues of penicillin and cleaning and sterilising solutions also impede culture growth. For low-fat or fat-free yogurt production the milk fat content of the milk is standardised by separating off some, or all of the fat. A normal (full-fat) yogurt has butterfat content greater than 3%. The fat content of a low-fat yogurt is greater than 1.5%, and for a fat-free yogurt about 0.1%. 2.2.2 Ingredients addition Dry ingredients, skimmed milk powder, sugar, stabilisers and emulsifiers, are weighed and added to a measured volume of milk in the manufacturing tank according to the recipe to produce the base mixture. 6 Skimmed milk powder is used to increase the total solids content of the milk to produce a firmer and more stable set when incubated. Stabilisers, gelatine and pectin for example, increase the viscosity of the product and help to minimise the risk of whey separation in the finished yogurt. 2.2.3 Stirring / heating The yogurt base mixture is heated to ~ 60 to 70°C while continuously being stirred to dissolve the ingredients. 2.2.4 High shear mixing The yogurt base mixture is thoroughly blended with a high shear mixer. 2.2.5 Homogenisation The mixture is passed through a homogeniser to break the milk fat globules into smaller sizes and aid even distribution throughout the mix. This process improves the stability and consistency of the yogurt by preventing fat separation. 2.2.6 Pasteurisation / cooling The yogurt base mixture is batch pasteurised at 90°C for 10 - 15 minutes then cooled to 35°C. This heat treatment provides a ‘clean’ medium for culture growth and also improves consistency by denaturing the whey proteins. 2.2.7 Culture addition A culture of harmless micro-organisms, which converts the milk sugar, lactose, into lactic acid, is added to the mixture and stirred. The yogurt can be filled at this stage and incubated in the pot if ‘set’ yogurt is required. 2.2.8 Incubation The yogurt mixture is incubated until the required acidity has been reached. Incubation temperatures and acidities may vary depending on cultures used and final product requirement. 2.2.9 Cooling and flavour addition The incubated yogurt mixture is cooled to ~ 12 - 15°C to retard any further increase in acidity. Colours, flavours, fruit etc. are added and mixed as required by the recipe. 2.2.10 Filling The finished yogurt is filled into pots and lids and labels applied. 2.2.11 Storage / testing The finished product is transferred to a cold store and cooled to below 4°C ready for despatch and sale. Product testing for compliance with legal requirements is carried out at this stage. 7 2.3 Yogurt process flow Ingredients addition Milk Skimmed milk powder Sugar Stabilisers Emulsifiers Manufacturing tank Stirring / heating (60 - 70°C) High shear mixing Homogenisation Pasteurisation (90°C for 10 - 15 min) Cooling (35°C) Culture addition Incubation Cooling (~10 - 15°C) Colour / flavour addition Filling / lid label application Cooling (below 4°C) Storage / testing 8 2.4 Capital and operating costs for yogurt manufacture The costing in this section was based on the procedure used for set yogurt manufacture with a daily production capacity of 100 litres of skimmed milk. The farm is a registered organic milk production farm and therefore the price used for costing reflects the prevailing ex-farm price for organic milk. The capital investment required for start-up of on-farm production is as follows: (See appendix 1) • Equipment, mostly reused £18,600 • Or alternatively use all new equipment £38,350 • Building premises, 7m x 3.5m food process area £30,625 Table 2.1 – Cost of production of organic yogurt Item Costs per day (pence) Using reused equipment Using new equipment Daily production costs Processing 234 234 Labour 3000 3000 Ingredients 3077 3077 Equipment 1488 2192 490 490 540 602 Product delivery 1000 1000 Building repairs 123 123 Return on capital 297 329 Return on working capital 571 663 Product storage 250 250 11070 11960 110.7 119.6 Sub total to produce 500ml 55.4 59.8 Packaging cost per 500ml 14.2 14.2 Buildings Daily admin and other running costs Admin and maintenance Sub total excluding packaging Sub total to produce 1 litre Total cost before profit 69.6 74.0 Profits at 20% 13.9 14.8 Ex-farm cost per 500ml 83.5 88.8 Note 1: Capital costs for equipment (new and second-hand) will depend on availability. Note 2: The prevailing milk price in this illustration was 28 ppl. Note 3: The costs for other packaging sizes can be evaluated by adding the cost of packing with the processed product. For example, cost of processed product for 200ml is 22.2p from the above table. The cost of plastic container and foil lid would be about 9p. Therefore, the total cost before profit would be 31.2p. Note 4: No two enterprises will be able to cost products similarly. Producers will need to carry out their own detailed costings. 9 Step Over Bench Area to remove outside clothing and footwear. Sit on bench swing legs over and put dairy protective clothing and footwear on. Boiler Mix Tank Shear Hand Wash Sink Drain Wash Sink Chilled Water Unit Drain Drainer Drain Rinse Sink Drain Incubation Tank (Optional) Hand Wash Sink Drain Drainer Air Compressor Pasteuriser (Batch) Raw Material Store (Ingredients) Drain Incubation Tank (Optional) Drain Rinse Sink Filling Machine Drain Wash Sink Yogurt Additions Area Drainer Packaging Store Please Note: Not to Scale Always consult the Local Environmental Health Officer (EHO) and Planning and Building Regulations departments at all stages. Chemical Store Toilet (with hand wash sink) Protective Clothing Personal Lockers Hand Wash Sink Covered Unloading Area Homogoniser Fig. 2.1 Hose 2.5 Yogurt production area outline plan Hose 10 Drain Drainer Cold Store Compressor Room Cold Store 4˚C Covered loading Area Section 3 – Ice Cream 3.1 Summary of business plan for Ice Cream – case study The calculations for this study are based on a pilot facility used for ice cream production for industrial training courses, students’ projects and for sales via an on-site shop. The daily production capacity is 100 litres using batch preparation method. The equipment required for ice cream making is as follows: • Raw milk storage tank • 100 litre jacketed tank for product mixing and heating • Homogeniser • 100 litre jacketed tank for cooling and storage of ice cream mix • Continuous ice cream freezer • Tub filler • Hot water boiler and air compressor When considering an appropriate building and equipment it is essential to involve the Environmental Health Officer (EHO) and Planning and Building Regulations Control at the earliest stages. It is also strongly recommended that an appropriately qualified and experienced technology consultant be used to progress planning permission and building regulation approval, and for the preparation of a robust HACCP system. Note 1: There are many different styles and types of ice cream for example: standard soft scoop, Italian, and frozen yogurt. Note 2: This example is based on premium ice cream from quality ingredients and whole milk; different technologies are used to produce different ice creams. Specialist advice should be taken from ingredients suppliers, equipment manufacturers, specialist consultants or organisations such as the Ice Cream Alliance. 3.2 Outline manufacture – Ice Cream Note: Rigorous hygiene standards must be observed at all stages of the process. 3.2.1 Ingredients addition Dry ingredients, skimmed milk powder, sugar, stabilisers and emulsifiers, are weighed and added to a measured volume of milk in the manufacturing tank according to the recipe to produce the base mixture. Skimmed milk powder is used to increase the total solids content of the milk. Stabilisers and emulsifiers improve the viscosity and texture of the finished product by binding in water molecules and assisting emulsification of the mix. 3.2.2 Stirring / heating The ice cream base mixture is heated to ~ 60 to 70°C while continuously being stirred to dissolve the ingredients. 3.2.3 High shear mixing A high shear mixer is used to thoroughly blend the mixture. 11 3.2.4 Homogenisation The mixture is passed through a homogeniser to break the milk fat globules into smaller sizes and aid even distribution throughout the mix. The correct combination of temperature and homogenisation pressure is important in helping to determine the consistency of the finished product. 3.2.5 Pasteurisation / cooling The homogeneous ice cream base mixture is gently agitated during batch pasteurisation at 66°C for minimum 30 minutes or 72°C for minimum 10 minutes then cooled to 7°C within 90 minutes. 3.2.6 Ageing / cooling The mixture is gently stirred and aged for between four and 12 hours then cooled further to below 5°C. During the ageing process the fat crystallises and the protein and stabilisers bind water to improve the consistency of the finished ice cream. 3.2.7 Holding / flavour addition The incubated ice cream mixture is held and colours, flavours, fruit etc added and mixed as required by the recipe. 3.2.8 Freezing / filling The mixture is frozen in a continuous ice cream freezer, which whips air into the mixture and disperses the water content in the form of small ice crystals. The finished ice cream is then filled into tubs or containers, and lids and labels applied. 3.2.9 Deep-freeze storage The finished product is transferred to a freezer at -18°C maximum in preparation for despatch and sale. Product testing for compliance with legal requirements is carried out at this stage. 12 2.3 Ice Cream process flow Ingredients addition Milk Skimmed milk powder Sugar Stabilisers Emulsifiers Manufacturing tank Stirring / heating (60 - 70°C) High shear mixing Homogenisation Pasteurisation (eg, 60°C for 30 min) Cooling (7°C) Ageing (~4 to 12 hours) Cooling (below 5°C) Holding Colour / flavour addition Freezing / filling Note: Different types / styles of ice cream use different types of ingredients and recipe timings. Please follow your ingredient suppliers’ recommendations Lid / label application Deep-freeze storage / testing 13 3.4 Capital and operating costs The system for ice cream making was a batch method of maximum capacity 100 litres. A standard recipe was used for calculation of the ingredients cost using milk, cream, sugar, skimmed milk powder and emulsifier / stabiliser. The capital investments required are as follows: (See appendix 2) • Capital required for equipment, using second-hand equipment £25,600 • Or alternatively using new equipment £75,600 • Capital for building premises, 7m x 3m £16,150 Table 3 - Cost of production of ice cream Item Costs per day (pence) Using reused equipment Using new equipment Daily production costs Processing 404 404 Labour 8000 8000 Ingredients 4903 4903 Equipment 1584 2520 431 431 769 2015 Product delivery 1000 1000 Building repairs 65 65 Buildings Daily admin and other running costs Admin and maintenance Return on capital 321 443 Return on working capital 1454 1565 Product storage 1200 1200 20131 22546 176.6 197.8 12.4 13.4 7.1 7.1 19.5 20.6 3.9 4.1 23.4 24.70 Sub total excluding packaging Sub total to produce 1 litre Sub total to produce 70g ice cream Packaging cost per 70g ice cream Total cost before profit Profits at 20% Ex-farm cost per 70g ice cream (typical pot size) Note 1: The costs of various other sizes of packed ice cream can be calculated from Table 3 – Cost of production of ice cream. For example, 50g of processed and frozen ice cream cost 8.8p and the packaging costs about 5.0p. This makes the total cost 13.8p before profits. With this particular product the volume of the final ice cream is larger due to incorporation of air. Therefore, a 50g of ice cream occupies a volume of 100ml at 100% overrun. That means the container size should be approximately 110ml to fill 50g of ice cream. Note 2: In this illustration the milk cost was 18ppl. Note 3: These costings are a guide only. The availability and price of equipment will vary depending on the area and time. 14 15 Step Over Bench Area to remove outside clothing and footwear. Sit on bench swing legs over and put dairy protective clothing and footwear on. Boiler Mix Tank Shear Hand Wash Sink Cold Store Compressor Drain Drain Wash Sink Hand Wash Sink Drain Drainer Air Compressor Pasteuriser (Batch) Drainer Raw Material Cold Store 4˚C (Ingredients) Chilled Water Unit Drain Raw Material Store (Ingredients) Homogoniser Ageing Tank Drain Drain Drain Drainer Rinse Sink Ice Cream Freezer Drain Wash Sink Packaging Store Covered Unloading Area Please Note: Not to scale Always consult your Local Environmental Health Officer (EHO) Planning and Building Regulations at all stages. Many production sites produce high quality ice cream with a simplified version of the adove. Chemical Store Toilet (with hand wash sink) Protective Clothing Personal Lockers Hand Wash Sink Covered Unloading Area Hose Fig. 3.1 Hose 3.5 Ice cream production area outline plan Homogoniser Drain Drainer Freezer Store Compressor Room FreezerStore -10˚C Covered loading Area Section 4 – Pasteurised milk 4.1 Summary of business plan - Milk pasteurisation and bottling This example of a farm in South Wales shows milk as the dairy product for on-farm production. The farm keeps about 100 cows and the daily milk yield in the summer is about 3000 litres. Previously farm milk was sold to a UK milk co-operative for processing. The opportunity was established to sell pasteurised bottled milk. It was necessary to build a new dairy to facilitate the processing and filling of milk. An initial production level of about 500 litres per day was considered satisfactory for these calculations. The equipment considered for this production is as follows: • Milk reception tank • Continuous milk pasteuriser at 500l/hr • Milk separator at 500l/hr • Homogeniser • Pasteuriser milk storage tank • Poly bottle filler • Chilled store • Batch cream pasteuriser • Hot water boiler and air compressor When considering an appropriate building and equipment it is essential to involve the Environmental Health Officer (EHO), and Planning and Building Regulations Control at the earliest stages. It is also strongly recommended that an appropriately qualified and experienced technology consultant be used to progress planning permission and building regulation approval, and for the preparation of a robust HACCP system. 4.2 Outline manufacture – Pasteurised milk 4.2.1 Pasteurisation / homogenisation / separation Raw milk is pumped to the pasteuriser balance tank and into the regeneration section of the pasteuriser plate pack where it is pre-heated to ~ 60 - 65°C. Whole milk processing: The milk passes into the heating section of the plate pack where it is subjected to the legally required temperature / time combination of 71.7°C minimum for 15 seconds. It is then cooled to 5°C and pumped into a holding tank. If required, homogenisation of the pre-heated milk takes place prior to the pasteurisation stage. Homogenisation breaks the milk fat globules into smaller sizes and distributes them evenly throughout the milk preventing them rising to the top forming a ‘cream’ line. Skimmed milk processing: The pre-heated milk at 60 - 65°C exits the pasteuriser plate pack and passes into a separator, which removes the cream. The cream is transferred to a raw cream storage tank prior to pasteurisation in a dedicated cream pasteuriser. 16 The skim returns to the heating section of the milk pasteuriser and is subjected to the legally required temperature / time combination of 71.7°C minimum for 15 seconds. It is then cooled to 5°C and pumped into a holding tank. Semi-skimmed milk processing: The pre-heated milk at 60 - 65°C exits the pasteuriser plate pack and passes into a separator, which removes the cream. Some of the cream is then blended back with the skimmed milk to provide the required butterfat content. This ‘standardised’ milk is then pumped to a homogeniser, which breaks up the fat globules into smaller pieces and distributes them evenly throughout the milk. It is then returned to the heating section of the milk pasteuriser and is subjected to the legally required temperature / time combination of 71.7°C minimum for 15 seconds. The semi-skimmed milk is then cooled to 5°C and pumped into a holding tank. The surplus cream is transferred to a raw cream storage tank prior to pasteurisation in a dedicated cream pasteuriser. 4.2.2 Filling / capping The cooled, pasteurised milk in the finished milk holding tank is pumped or gravity fed into a filling machine. Bottles are filled, capped and have labels and codes applied prior to being crated and transferred to cold storage at less than 5°C in preparation for despatch and sale. Product testing for compliance with legal requirements is carried out at this stage. 17 4.3 Pasteurised milk process flow Raw milk Pasteuriser plant Pre-heating (60 - 65°C) Pasteurisation (71.7°C for 15 sec.) Separation Standardisation (skim and semi skim) Cooling (5°C) Holding Homogenisation (if required) Surplus cream Cream pasteurisation Filling / capping Cream filling / capping / label / code Label / code Cold store (Below 5°C) 18 4.4 Capital and operating costs – Milk processing and bottling The production unit in this example uses a continuous plate pasteuriser. A homogeniser is required to produce homogenised milk. The aim is to produce 500 litres of pasteurised milk per day but the capacity will allow for doubling the output. The capital investment required is estimated as follows: (See appendix 3) • Capital for equipment – using second hand equipment £27,500 • Or alternatively using new equipment £53,800 • Capital for building premises, 8m x 3m £34,800 Table 4 – Cost of production of pasteurised milk Item Costs per day (pence) Using reused equipment Using new equipment Daily production costs Processing 470 470 Labour 4800 4800 Ingredients 8925 8925 Equipment 2200 2690 696 696 718 1138 Product delivery 1000 100 Building repairs 140 140 Return on capital 434 508 Return on working capital 377 644 Product storage 250 250 20010 21261 40.0 42.5 7.8 7.8 47.9 50.4 9.6 10.1 57.5 60.5 Buildings Daily admin and other running costs Admin and maintenance Sub total excluding packaging Sub total to produce 1 litre Packaging cost per litre Total cost before profit Profits at 20% Ex-farm cost per litre Note 1: Other packed sizes can be calculated using the cost of processed milk and adding the packaging cost. For example, cost of two litres of processed milk is 80p and cost of two-litre poly bottle and cap is bout 10.7p making the total cost of 90.7p before profits. Note 2: The prevailing milk price used in the example was 18ppl. Note 3: These costings are only a guide. The availability and price of equipment may vary. Ensure you consult your financial advisor before proceeding. 19 Hand Wash Sink Personal Lockers Area to remove outside clothing and footwear. Sit on bench swing legs over and put dairy protective clothing and footwear on. Chilled Water Unit Drain Air Compressor Past. Milk Tank Raw Milk Tank Drain Milk Bottle Filling Drain Hydrogeniser Seperator Milk Pasteuriser Drain Drainer Rinse Sink Wash Sink Drainer Cream Filling Cream Batch Past. Packaging Store Covered Unloading Area Please Note: Not to scale Always consult your Local Environmental Health Officer (EHO) Planning and Building Regulations at all stages. Many production sites produce high quality ice cream with a simplified version of the adove. Boiler Toilet (with hand wash sink) Protective Clothing Fig. 4.1 4.5. Milk processing area outline plan Hand Wash Sink 20 Cold Store Compressor Room Cold Store 4˚C Covered loading Area Section 5 - Appendices Appendix 1 Capital items for Yogurt manufacture, 100 litre batch per day Building premises (7m x 3.5m x 2m high) – cost at £1,250/m2 would be £30,625 Capital for Equipment £ Second Hand £ New 4,500 10,300 Separator 1,000 3,500 Walk in chilled store 5,000 7,500 Product Chiller x 2 3,400 5,500 Yogurt pump 850 3,600 Raw milk tank 900 3,500 Compressor (air) 200 600 Hot water boiler 600 800 Dish washer 300 500 1,600 2,300 250 250 18,600 38,350 Batch pasteuriser Pot sealer Buckets, jars etc Total Appendix 2 Capital items for ice cream manufacture, refurbished premises (7m x 3m x 2m high) – Refurbishment of floors, walls ceilings and drains £16,150 Capital for Equipment £ Second Hand £ New Jacketed tanks, 100 litres x 2 3,200 15,800 Homogeniser 5,500 18,500 Continuous freezer 2,000 15,000 Pipes, fittings 300 300 Hot water boiler 600 800 Compressor (air) 200 600 5,800 14,200 200 400 7,800 10,000 25,600 75,600 Cup filler Trays and ancillary items Large freezer store Total 21 Appendix 3 Capital items for milk pasteurisation and bottling Building premises (8m x 3m x 2m high £ New building, fabric only 19,200 Walls and ceiling 5,100 Epoxy floor 1,800 Electrics 6,000 Wash basin, hygiene equipment 2,700 Total 34,800 Process equipment Pasteuriser 500 l/h £ Second-Hand £ New 2,500 14,000 Balance tank 400 800 Homogeniser 7,800 12,000 Separator 1,000 3,500 Poly bottle filler 8,500 11,900 Pipes, valves, pump 3,500 5,000 Pasteurised milk tank 2,500 4,000 600 800 Hot water boiler Compressor (air) 200 600 Batch cream pasteuriser 500 1,200 27,500 53,800 Total 22 This booklet and the information within are intended as a guide only. Costs stated are approximate and were felt to be representative at time of going to press. Please seek detailed support from your accountant, bank, legal advisor or other specialist support organisations available in pdf and printed copy format from the DairyCo, formerly the Milk Development Council Disclaimer: DairyCo seeks to insure that the information contained within this publication is accurate. However, DairyCo shall not in any event be liable for loss, damage or injury howsoever suffered directly or indirectly in relation to information contained within this publication, and no liability will be accepted for errors or omissions. The contents of this publication may not be reproduced in whole or in part without the consent of DairyCo. 23 Trent Lodge Stroud Road Cirencester Gloucestershire GL7 6JN T: +44 1285 646500 F: +44 1285 646501 E: [email protected] www.dairyco.org.uk December 2008

© Copyright 2026