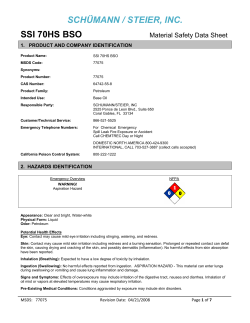

Document 16922