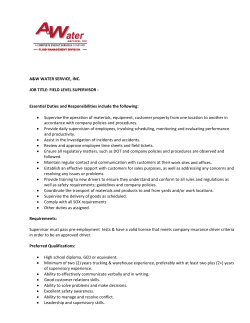

BURLINGTON COUNTY BOARD OF CHOSEN FREEHOLDERS