Bentley Solutions for the Digital Factory

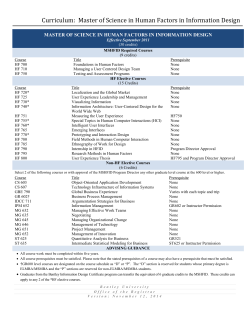

Redefining the Digital Factory Integrating the Factory Lifecycle with PLM Lutz Bettels, Vice President Manufacturing & Facilities, Bentley Systems Inc. Bentley Systems Inc. – a global software leader 2 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the World‘s Infrastructure … 3 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Site Infrastructure and Master Planning Operate Build – Geospatial Mapping – Surveying Data Display – Utility Planning and Documentation – Site Design and Civil Engineering – Site Master Planning 4 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Design Bentley Solutions for the Digital Factory • Space Programming and Block Layout – – – – – – Import space program and schedules from Excel Create block layouts in 2D or 3D Run graphical space reports (thematic maps) Query data model and analyze space layout Create professional space schedules Integrate reporting tools 5 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Factory Design (BIM) incl. Point Cloud Data – Architectural Design • Any building types (factories, warehouses, offices …) – Structural Design and Analysis • Building structures, platforms, conveyors – Building Mechanical Design • HVAC, plumbing, media – Building Electrical Design • Raceways, cabeling, lighting, network, security 6 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • JT Data Exchange – – – – – JT import, export and referencing 3D clipping capabilities to export partial models Support of levels and structured data export Level of detail support File size and performance optimizations 7 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Teamcenter Integration – Automaticaly generate JT renditions of factory model in continuous quality – Distribute partial factory JT models and PLMXML to process engineering – Receive process layouts through JT and PLMXML in factory design and layout 8 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Point Clouds for Layout and Design Validation – Leverage point cloud directly for early phase layout design – Evaluate early layout designs without need for 3D modeling – Validate 3D layouts in context of or against point clouds 9 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory Courtesy of Volvo 10 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Factory DMU – Reference process layout in digital factory model to create mockup model – Inspect complete digital factory model – Perform clash detections and identify interferences – Create markups and distribute in factory design, layout and process engineering – Manage versions and revisions 11 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Construction Management and Progress Monitoring – Define work packages and analyze construction sequenzing – Distribute work packages to contractors and capture construction status with mobile devices – Monitor construction progress through status visualization in digital factory model – Compare as-built scanned vs. as-designed 3D model throughout construction to avoid subsequent errors and omisions 12 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory 13 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory 14 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated 15 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Bentley Solutions for the Digital Factory • Asset Lifecycle Information and Performance Management Master Asset Register Change Events Asset People Asset Organizations Location Documents Drawings Transmittals Federated Factory World Requirements 16 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Impact analysis Bentley Solutions for the Digital Factory • Bentley completes the Digital Factory with solutions for: – – – – – – – – – Site infrastructure and master planning Space programming and block layout Factory design (BIM) and layout As-built point cloud data utilization, editing and management Process engineering integration through JT Information mobility with Teamcenter Factory DMU Construction Management Asset lifecycle and performance management 17 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Redefining the Digital Factory Seamless Integration of Factory Infrastructure Design and Manufacturing Engineering 18 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Digital Factory Building Blocks for Discrete Manufacturing Factory Process Product Process Factory 19 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Product Process and Factory Planning Fields Building Floor Line Cell Operation Single Process 20 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Process Planning Product Engineering Software Manufacturing Engineering Software (Process Design, Simualte and Program) Orders Purchasing CAD Plant BOM CAE Mass BOM BOP Prototype Testing ERP Production Planning Serial Planning Software Siemens PLM Software Integrated Product/Production Definition Process Planning Environment • Product Design, Analysis and Simulation • Tool and Equipment Design • Process and Resource Planning • Manufacturing Sequencing and Workflows • Process Analysis and Simulation • BOM and SAP Integration • Manufacturing Cell and Line Layout • Production Simulation 21 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Plant Floor Devices Quality Factory Planning Asset Information Management Engineering Work-In-Progress Management Pointtools Master Planning Bentley Map Factory Model AECOSim Building Designer Factory Layout Facilities Space Planner Site Infrastructure Bentley sisnet Detailed Factory Layout & Design Factory As Built Scan Factory DMU Building, HVAC, Electrical, Media AECOSim Building Designer Conveyor Systems MicroStation Logistics Facilities Space Planner Bentley Navigator Clash Resolution AECOSim Building Designer Bentley Facilities eB Asset Performance Management Ivara Operate Factory Infrastructure Design & Build Factory Planning Environment • Building Design • HVAC and Electrical • Structural Analysis. • Integration to Production Systems • Conveyor System Layout and Design • Visualization and Interference Detection • Factory Layout (overall, line, cell) • Factory Mockup • Energy Simulation 22 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Factory As Built Documentation Bentley Siemens Positioning Building Floor Line Cell Operation Single Process 23 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Product Lifecycle Complements Factory Lifecycle Product Engineering Software Manufacturing Engineering Software (Process Design, Simualte and Program) Orders Purchasing Plant BOM Mass BOM Prototype CAD CAE BOP Software Testing ERP Production Planning Serial Planning Plant Floor Devices Quality Siemens PLM Software Integrated Product/Production Definition JT JT JT Asset Information Management Engineering Work-In-Progress Management Factory Model Pointtools Building Designer Master Planning Bentley Map AECOSim Factory Layout Facilities Space Planner Site Infrastructure Bentley sisnet Detailed Factory Layout & Design Factory As Built Scan Factory Infrastructure Design & Build 24 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Building, HVAC, Electrical, Media AECOSim Building Designer Conveyor Systems MicroStation Logistics Facilities Space Planner Factory DMU Bentley Navigator Clash Resolution Factory As Built Documentation AECOSim Building Designer Bentley Facilities eB Asset Performance Management Ivara Operate Integrated manufacturing process planning and factory layout design Detailed Production Planning DEVELOP BUILD SUPPORT 3 Robot line engineering Production Planning Factory Planning OEM OEM Line Builder PLAN 2 • Planning a new body-in-white line in an existing facility (brown field project) 5 Process planning in factory context Update planning and validation 4 1 3D factory and point cloud model 25 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Detailed factory design and analysis • Integrated workflow scenario for process planning and factory layout • Challenging scenario due to data amount and complexity Line Builder Detailed Production Planning OEM Production Planning Integrated Workflow for Process and Factory Design based on JT Visualization Standard Format Robot Line Engineering Line Layout Concept Process & Layout 3 Detailed Process & Layout Process Planning in Factory Context Update Planning and Validation 2 5 Factory Planning OEM Factory Layout Model Line Layout & Clearance Zones Detailed Factory Layout Model 3D Factory and Point Cloud Model Detailed Factory Design and Analysis 1 4 26 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Integrated manufacturing process planning and factory layout design PLAN DEVELOP BUILD SUPPORT • Planning a new body-in-white line in an existing facility (brown field project) • Integrated workflow scenario for process planning and factory layout • Challenging scenario due to data amount and complexity 27 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated 28 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Factory As-Built Model Advantages Benefits Collect existing 3D designs and 2D layouts in one environment Accurate and up to date 3D as built information model Perform and incorporate 3D laser scans in factory model Aggregate information to be passed on to Process Design Prepare 2D space program in 3D factory context Leverage point clouds to make early layout decisions Build 3D factory information model on top of point cloud 29 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated High quality initial layout related to 3D factory model 30 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Process Planning Concept Advantages Benefits Process planning in building context Synchronize process and factory development stages faster and with greater collaboration Start concept process planning with current plant layout Sharing 3D-footprints between manufacturing engineering and facilities engineering through JT Process (change) validation in as-built point cloud scans 31 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Align virtual production model and physical production equipment 32 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Detailed Planning and Validation by Supplier Advantage Benefits Detailed cells and line planning by line builder • Synchronize process engineering development stages faster between OEM and supplier • Analyze the impact of changes quickly and continuously improve with iterative validation Robot programming & validation Robots smart placement for best location of robot Resulting in consolidated line design 33 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated 34 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated 35 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Volvo Cars – Case Study with Point Clouds and Tecnomatix 36 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Detailed Factory Layout Advantages Benefits Complete factory layout and design (HVAC, Electrical, Media) with process engineering context Reduce factory design iterations by incorporating relevant process design information in factory layout process Update laser scans into 3D information model Avoid errors and omissions because of factory mockup Perform Factory DMU between product, process and factory Decrease effort for creating building performance simulations 37 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated 38 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated Update Process Planning Advantage Benefits Update process planning after collision was found in factory layout • React quickly to changes by creating process plans and factory design more efficiently Process change in the context of the real factory layout • Connecting distributed people with the right information in the right context on time Send collision free line design back to factory layout design 39 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated For more information: 1-800-BENTLEY (1-800-236-8539) www.bentley.com 40 | WWW.BENTLEY.COM | © 2012 Bentley Systems, Incorporated

© Copyright 2026